TIGHT OIL

Site

Contents

Restoring

Our Oil Independence

Contents

Restoring

Our Oil Independence

Chapter 3, Page 1:

The Early Thorium-Fueled Molten Salt Reactors

< Chapter >

Page 2 >

Categories:

INTRODUCTION

*

"The potential utility of a

fluid-fueled reactor that can operate at a high temperature but with a

low-pressure system has been recognized for a long time. Some years ago, R. C.

Briant of the Oak Ridge National Laboratory suggested the use of the molten

mixture of UF4 and ThF4, together with the fluorides of the alkali metals and

beryllium or zirconium, as the fluid fuel. Laboratory work with such mixtures

led to the operation, in 1954, of an experimental reactor, which was designated

the Aircraft Reactor Experiment (ARE).

Fluoride-salt mixtures

suitable for use in power reactors have melting points in the temperature range

850 to 950°F and are sufficiently compatible with certain nickel-base alloys to

assure long life for reactor components at temperatures up to 1300°F. Thus the

natural, optimum operating temperature for a molten-salt-fueled reactor is such

that the molten salt is a suitable heat source for a modern steam power plant.

The principal comparison with one or more of the other fluid-fuel systems are

(1) low pressure operation, (2) stability of the liquid under radiation, (3)

high solubility of uranium and thorium (as fluorides) in molten-salt mixtures,

and (4) resistance to corrosion of the structural materials that does not depend

on oxide or other film formation.

The molten-salt system has

the usual benefits attributed to fluid-fuel systems. The principal advantages

over solid-fuel-element systems are (1) a high negative temperature coefficient

of reactivity, (2) a lack of radiation damage that can limit fuel burnup, (3)

the possibility of continuous fission-product removal, (4) the avoidance of the

expense of fabricating new fuel elements, and (5) the possibility of adding

makeup fuel as needed, which precludes the need for providing excess reactivity.

The high negative temperature coefficient and the lack of excess reactivity make

possible a reactor, without control rods, which automatically adjusts its power

in response to changes of the electrical load. The lack of excess reactivity

also leads to a reactor that is not endangered by nuclear power excursions.

One of the attractive features

of the molten-salt system is the variety of reactor types that can be considered

to cover a range of applications. The present state of the technology suggests

that homogeneous reactors which use a molten salt composed of BeF2 and either

Li7F or NaF, with UF4 for fuel and ThF4 for a fertile material, are most

suitable for early construction.

These reactors can be either

one or two region and, depending on the size of the reactor core and the thorium

fluoride concentration, can cover a wide range of fuel inventories, breeding

ratios, and fuel reprocessing schedules. The chief virtues of this class of

molten-salt reactor are that the design is based on a well-developed technology

and that the use of a simple fuel cycle contributes to reduced costs.

With further development, the

same base salt, that is, the mixture of BeF2 and Li7P, can be combined with a

graphite moderator in a heterogeneous arrangement to provide a self-contained

Th-U233 system with a breeding ratio of one. The chief advantage of the

molten-salt system over other liquid systems in pursuing this objective is that

it is the only system in which a soluble thorium compound can be used, and thus

the problem of slurry handling is avoided. The possibility of placing thorium in

the core obviates the necessity of using graphite as a core-shell material.

Plutonium is being

investigated as an alternate fuel for the molten-salt reactor. Although it is

too early to describe a plutonium-fueled reactor in detail, it is highly

probable that a suitable PuF3-fueled reactor can be constructed and operated.

The high melting temperature

of the fluoride salts is the principal difficulty in their use. Steps must be

taken to preheat equipment and to keep the equipment above the melting point of

the salt at all times. In addition, there is more parasitic neutron capture in

the salts of the molten-salt reactor than there is in the heavy water of the

heavy-water-moderated reactors, and thus the breeding ratios are lower. The

poorer moderating ability of the salts requires larger critical masses for

molten-salt reactors than for the aqueous systems. Finally, the molten-salt

reactor shares with all fluid-fuel reactors the problems of certain containment

of the fuel, the reliability of components, and the necessity for techniques of

making repairs remotely. The low pressure of the molten-salt fuel system should

be beneficial with regard to these engineering problems, but to evaluate them

properly will require operating experience with experimental reactors." - -

*By H. G. MacPherson.

http://www.energyfromthorium.com/pdf/FFR_part2.pdf

Genesis of the Naturally Safe,

Thorium-fueled, Molten Salt Reactor

Molten Salt Reactor:

The reactor technology path not taken.

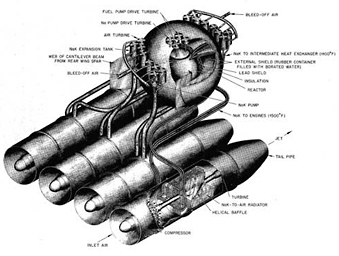

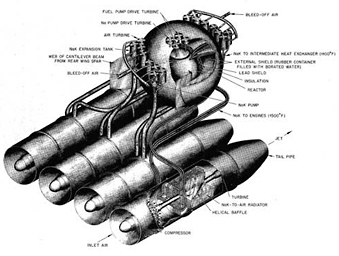

A very light and very powerful

molten salt reactor was developed to power nuclear

bomber airplanes a few years

before Intercontinental Missiles were developed.

The NB-36 made nearly 50 flights in the 1950s

carrying an operating nuclear reactor. The crew worked from a

lead-shielded cockpit.

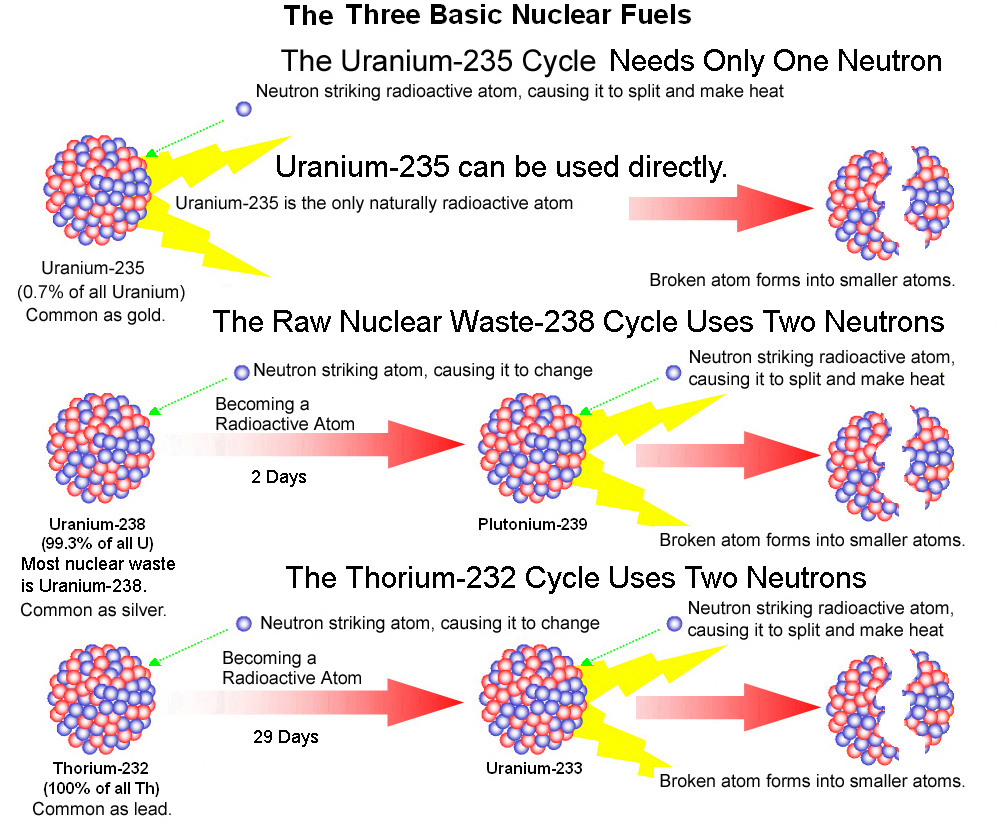

Thorium:

The nuclear energy path not taken.

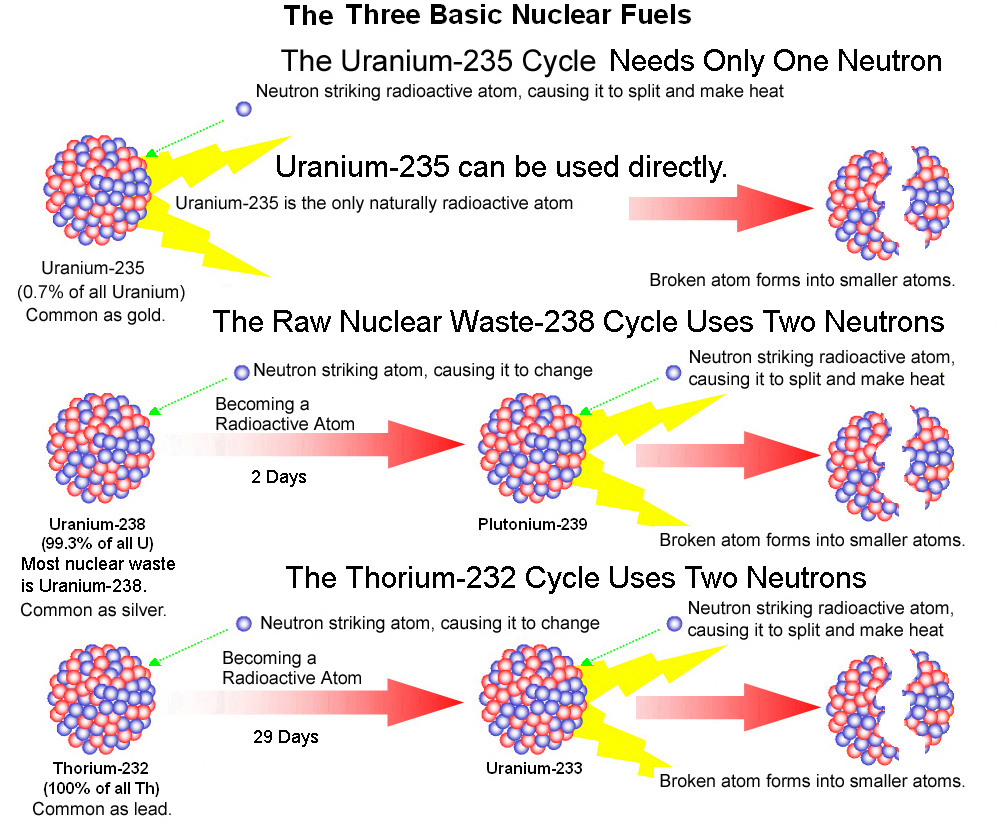

By the time the Manhattan

Project was completed 3 viable nuclear energy paths were identified: Uranium,

Plutonium, and Thorium.

Thorium had very poor weapons potential and was subsequently abandoned and forgotten.

(Left) The

NB-36's "Fireball" reactor using dissolved uranium liquid fuel and

the 4 nuclear jet engines it powered. It has little in common with

today's solid core reactors.

(Right) The USS Nautilus got the first operational solid fuel nuclear reactor.

A major objection to nuclear airplanes was the

possibility of a crash in a large city.

Today's low temperature (550°F) solid fuel core

power plant reactors are massively scaled up versions of the first desk-size submarine solid-fuel core reactors.

They are not hot enough to duplicate the

efficient superheated steam coal makes in a

coal-burning power

plant. The very hot

(1,300°F) liquid fuel

core in airplane nuclear reactors can easily duplicate, and thus replace, any

any steam found in any coal or natural gas power plant.

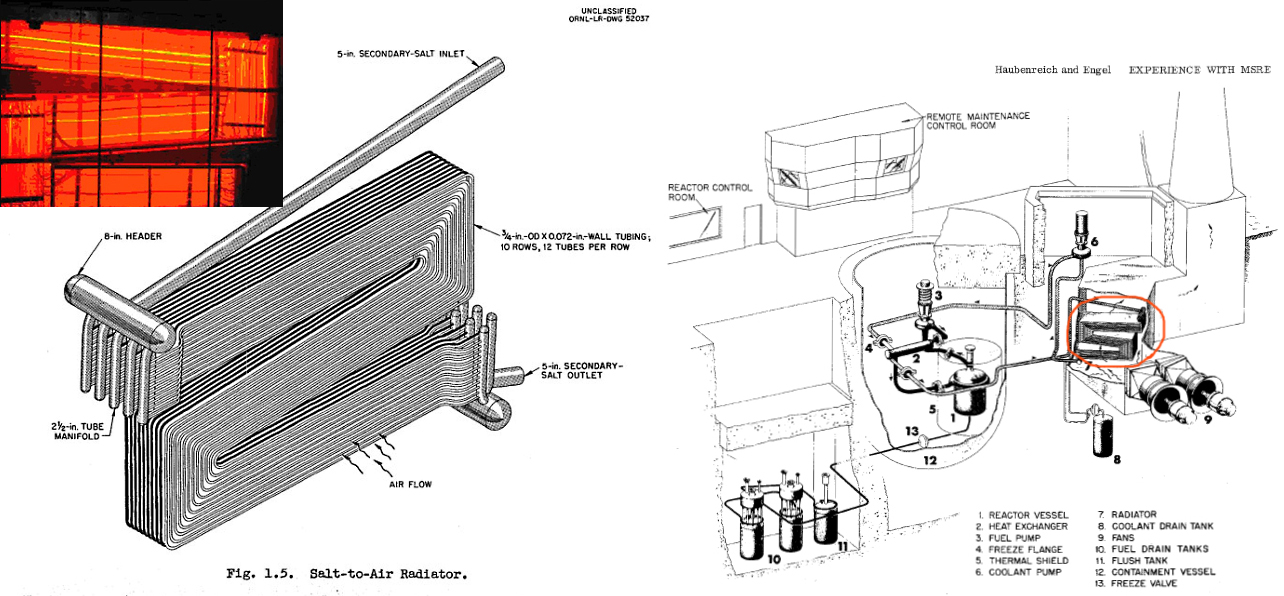

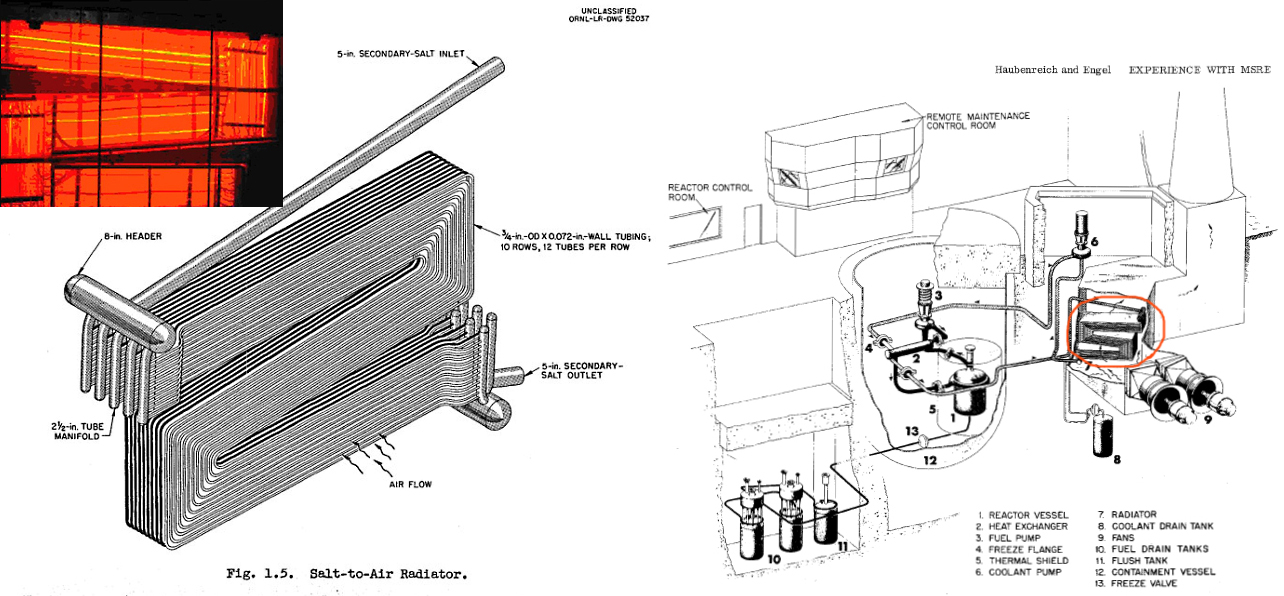

(Right) The Molten Salt Reactor Experiment salt-to-air heat exchanger ran so hot it glowed like the burners on your kitchen range.

(Click on chart to prove to yourself how hot it was. The chart is in Kelvin, an

absolute temperature measurement. 1,300°F = 978 K )

Also:

Color temperature

Liquid Reactors: May, 1946, marked the beginning of

the ultra-secret nuclear powered bomber program that eventually progressed as

far as the NB-36H bomber.

By 1955, this program

produced the successful X-39 jet engine - two modified General Electric J47

jet engines with reactor-heated heat exchangers replacing the standard jet engine's

jet fuel combustors - and

would probably have gone on to power the X-6 successor to the NB-36H had that program been

pursued. Nuclear powered airplane

programs were eventually abandoned in favor of far faster, more difficult to

intercept, intercontinental ballistic missiles.

as

far as the NB-36H bomber.

By 1955, this program

produced the successful X-39 jet engine - two modified General Electric J47

jet engines with reactor-heated heat exchangers replacing the standard jet engine's

jet fuel combustors - and

would probably have gone on to power the X-6 successor to the NB-36H had that program been

pursued. Nuclear powered airplane

programs were eventually abandoned in favor of far faster, more difficult to

intercept, intercontinental ballistic missiles.

The airplane engine's nuclear

reactor was extremely light, simple, fast

responding, powerful,

and hot enough to replace jet fuel. The uranium nuclear fuel, dissolved in molten salt,

flowed through the reactor and its heat exchangers much like energy-transporting

blood flows through the organs of animals. Unlike water, 1,300°F molten

salt produces no vapor pressure and, as a consequence, the reactor cannot

explode like conventional high pressure steam nuclear reactors.

Later, a slightly larger version

of the same type of reactor was built in the same aircraft reactor development

building at Oak Ridge National Laboratories. Completed in 1965, it was

called the "Molten Salt Reactor Experiment" (MSRE) and, over the next 5 years,

ran at full power for the equivalent of one and a half years.

Thorium: The

nuclear energy path not taken.

By the time the Manhattan Project was

completed, 3 viable nuclear energy paths were identified: Uranium, Plutonium, and

Thorium. Thorium had very poor weapons potential and was subsequently abandoned as

being suitable for weapons.

Later, along with uranium and plutonium, thorium was explored as a potential

reactor fuel in both solid fuel reactors (Shippingport, near Pittsburgh, PA) and liquid fuel reactors

(Oak Ridge Molten Salt Reactor Experiment - MSRE).

Unlike polyisotopic

uranium

(

http://en.wikipedia.org/wiki/Isotope ), thorium is monoisotopic and

therefore does not need costly enrichment to be used as nuclear fuel.

Several combinations of liquid reactors and thorium fuels appear to be ideal for

making cheap,

extremely hot heat for millions of years. Unlike solid fuel reactors

which cannot consume more than several percent of their uranium fuel before

becoming too weak to run, liquid fuel reactors are capable of almost completely

consuming their nuclear fuel, and, as a consequence, produce about 250 times the

heat and 1% the nuclear waste of a solid fuel reactor. Further, most of

this small amount of nuclear waste decays to a safe level in less than a decade,

the remainder in several hundred years.

This combination of running

coal-hot and load-following while making about 250 times as much heat and

producing 1% the waste - in a far less expensive to build reactor - attracted

great interest from the electrical utilities. Conceptual designs for large,

utility size molten salt reactors were on the drawing boards as early as 1960.

Today, heat

from thorium could be 8,000 times cheaper than heat from coal.

We have arrived at energy's final frontier where all

of civilization's heat must come from nuclear.

Burning our last remaining deposits of oil, natural gas, and coal will only make

Global Warming worse. The hydrocarbons in oil, natural gas, and coal are

far more valuable for bringing us good lives by using them as feedstock for

plastics and fertilizers rather than wasting them as mere sources of heat.

This book is about re-starting

America's thorium-fuelled molten salt reactor program using a modern version of

the 1972 EBASCO 1,000 megaWatt electricity generating plant reactor.

The Single Fluid (Converter) Thorium-Powered Liquid Reactor

________________________________________________________________________________________

________________________________________________________________________________________

Reactor Safety

Reactor Safety

MSR - Reactor Safety .pdf

How are they "Naturally Safe"?

If,

for any reason, the reactor gets too hot,

a freeze plug in the reactor tank’s bottom melts, causing the reactor's

fuel-carrying molten salt to drain away from the graphite rods down into

passively air cooled dump tanks (blue) located beneath the reactor. There,

away from the graphite rods, the chain reaction ceases and the molten salt will

cool and solidify. Solidification prevents the radioactive materials from

entering the environment. Heaters re-melt the salt to restart the reactor.

Radiation Leakage

Radiation leakage. In this type of

reactor there are 2 or more loops of circulating melted salt. 1) The

inner loop carries the dissolved radioactive fuel

(called "Fuel Salt") first to the reactor's core, where the fuel in

the salt heats the salt, then to a heat exchanger where the salt's heat is

transferred to the outside world via 2) a second loop of melted salt (called

"Clear Salt"). The fuel salt loop is completely contained within

the confinement cell.

In the unlikely event some fuel salt escaped the

confinement cell, it will turn solid when it cools below 680°F. So there

would be a solid lump you could easily locate. Today's conventional

reactors leak radioactive water which quickly sinks into the ground, dispersing

unstoppable

radioactivity far and wide into the

environment.

Unlike table salt, the fuel salt lump would take a long time to dissolve in

rain. At

2.7grams/liter of water,

FLiBe, the salt used to carry radioactive fuel in this reactor, has 133 times

less solubility in water than common table salt at

359 grams/liter of water.

Unlike water, FLiBe cannot become radioactive through

exposure to radioactivity, so if the secondary loop leaks, its just a chemical

spill. You won't be able to find these lumps with a Geiger counter.

Unlike table salt, FLiBe is not safe to eat.

________________________________________________________________________________________

The Thorium Reactor Libraries

How mature is the single-fluid

"converter" molten salt reactor?

How mature is thorium as a nuclear fuel?

The Thorium-Fueled Molten

Salt Reactor

Libraries

Oak Ridge National Laboratories is

a reputable organization and they have hundreds of documents about

several

experimental molten salt reactors, HTRE-1, HTRE-2, HTRE-3, and MSRE,

which ran for about 5 years, some of the time on liquid thorium.

Also, the Shippingport reactor

ran for several years on solid thorium.

ran for several years on solid thorium.

The author knows of no reason to doubt the accuracy of these documents.

These documents may be found, examined, and downloaded without restriction at:

http://moltensalt.org/references/static/downloads/pdf/index.html Bruce

Hoglund's web site ORNL collection.

http://www.energyfromthorium.com/pdf/ Kirk Sorensen's web site ORNL

collection.

MSR - The Molten Salt

Adventure .pdf NUCLEAR SCIENCE AND ENGINEERING: 90, 374-380 (1985)

"The Molten Salt Reactor Adventure" H. G. MacPherson, Consultant, Oak Ridge,

Tennessee 37831, Accepted March 15, 1985

MSR - Safety and Licensing Aspects of the Molten Salt Reactor - 120507.pdf

________________________________________________________________________________________

About Naturally Safe

Liquid Thorium Reactors

ABOUT NATURALLY SAFE LIQUID THORIUM REACTORS

Liquid Thorium Reactors Have Little In Common With Today's Reactors

WHAT THEY ARE, HOW THEY WORK,

how their NATURAL SAFETY FEATURES WORK

Good article by Dr Ralph Moir and Dr. Edward Teller, (inventor of

the hydrogen bomb) explaining a single fluid reactor:

Thorium-Fueled Underground Power Plant

Good article by Dr. Ralph Moir and Dr. Robert Hargraves explaining dual fluid

reactors:

www.energyfromthorium.com/forum/download/file.php?id=791

Note: Like

gasoline engines, there are several different kinds of single fluid reactors.

This is the one that has been built and tested twice.

The Single Fluid (Converter)

Thorium-Powered Liquid Reactor

"A pot, a pump, and a pipe."

- Oak Ridge National Laboratories quip.

Advantages

Walk-away safe.

Extremely simple. Fire hot.

Almost limitless amounts of extremely cheap thorium for fuel.

Produce 1% the nuclear waste of a conventional reactor. Naturally safe

slow neutron nuclear device (atomic bombs are fast neutron nuclear devices).

Small and very cheap for the amount of heat they produce.

Cannot be kept from ending fission upon loss of electricity.

No steam pressure, so can't explode. Run 30 years at full power between

maintenances. Air cooled, can be used in deserts.

Can be installed in underground silos for maximum isolation.

Can be installed in concrete barges so they can be hauled away forever when no

longer needed, leaving no residual radioactive materials at user's site.

The heat transfer cooling salt contracts when it freezes solid so it doesn't burst the pipes.

If any of the heat transfer cooling salt leaks, it turns solid so the radioactivity can't sink into

the ground and make drinking water radioactive like the cooling water from

conventional reactors. You just scoop it up with a very long handle

shovel. Largely naturally self-heat-regulating and

thus load-following: Fuel density changes in the heat transfer salt tend to make

it become warm when it is cool, cool when it is warm.

Disadvantages

Fire hot - runs red-hot. The

heat transfer cooling salt is expensive. The heat

transfer salt that has the radioactive fuel dissolved in it has to be immune to

radioactivity forever. That stuff is very expensive.

The heat transfer cooling salt turns solid if allowed to get too cool.

The heat transfer cooling salt is corrosive so the reactor tank and circulating

pumps have to be made out of expensive Hastelloy-N.

Molten salt reactors are radioactive like

all other nuclear reactors. Special equipment will

be needed for the 30 year maintenance. Unlike

table salt, FLiBe heat transfer salt is toxic like the chlorines. Its

fumes cannot be breathed, it cannot be eaten, it cannot be handled with bare

hands.

________________________________________________________________________________________

The Single

Fluid (Converter) Thorium-Powered Liquid Reactor

The Single Fluid (Converter) Thorium-Powered

Liquid Reactor

Introduction:

We are talking about a

combination of TWO entities:

1. Thorium instead of Uranium as a

nuclear fuel.

2. Unpressurized (incapable of exploding) molten salt cooled liquid fuel

reactors instead of

high pressure (capable of exploding) water cooled solid fuel rod reactors.

A QUICK INTRODUCTION TO THE BASIC "CONVERTER" MOLTEN SALT REACTOR

1.

Solid salt, if heated hot enough, will melt into a clear water-like liquid

(color-coded yellow in sketch at right). At the temperatures discussed here, the salt is far

below its boiling point and, since the salt has little vapor pressure, Molten

Salt reactors are unpressurized and thus incapable of making a steam-like

explosion.

(Click on image for larger view.)

2.

Uranium and Thorium can be dissolved in molten salt.

A tub of molten salt with some radioactive uranium dissolved in it (think blood

- which carries nutrients) will become a

nuclear reactor if rods of synthetic non-flammable "nuclear" graphite (vertical black bars in reactor sketch) are

inserted into the liquid salt pool to promote nuclear fission (think muscle -

which turns nutrients into energy).

Once

running, adding more uranium will keep it running. If non-radioactive

thorium-232 is added instead, the radioactivity will convert

thorium-232 into radioactive uranium-233 (this takes about a month) and the

reactor will continue to run. Radioactive plutonium-239 can also be used

to start and run the reactor.

3.

"Cruise Control" As

the pool becomes hotter, the liquid salt expands, reducing the concentration of

radioactivity near the graphite rods, thereby reducing the intensity of the

nuclear chain reaction. As the pool becomes cooler, contraction of the

liquid salt intensifies the chain reaction, making the fuel salt hotter. A Molten Salt reactor will “load follow” (think

“cruise control”) over a surprisingly large portion of its power range.

Control rods will bring the reactor down to "idle" or allow full

power.

4.

The first heat exchanger heats a second loop of clear non-radioactive

molten salt called "coolant salt." This salt is used to safely carry the reactor's heat to

the outside world. Coolant salt then heats the second heat exchanger to

make steam to drive an electricity generator.

5.

Fresh make-up thorium is added as needed for up to thirty years

- at which

time the fuel salt becomes saturated and has to have its dissolved waste products removed

by precipitation.

How are they "Naturally Safe"?

6. If,

for any reason, the reactor gets too hot,

a freeze plug in the reactor tank’s bottom melts, causing the reactor's

fuel-carrying molten salt to drain away from the graphite rods down into

passively air cooled dump tanks (blue) located beneath the reactor. There,

away from the graphite rods, the chain reaction ceases and the molten salt will

cool and solidify. Solidification prevents the radioactive materials from

entering the environment. Heaters re-melt the salt to restart the reactor.

Thorium's Proliferation Risk

"Thorium fueled [breeder] reactors

may pose a slightly higher proliferation risk than uranium based

reactors because, while Pu-239 will fairly often fail to undergo

fission after neutron capture and produce Pu-240, the corresponding

process in the thorium cycle is relatively rare. Thorium-232

converts to U-233, which will almost always undergo fission

successfully, meaning that there will be very little U-234 produced

in the reactor's thorium/U-233 breeder blanket, and the resulting

pure U-233 will be comparatively easy to extract and use for

weapons. However, the opposite process (neutron knock-off)

happens as a matter of course, producing U-232, which has the strong

gamma emitter Tl-208 in its decay chain. These gamma rays complicate

the safe handling of a weapon and the design of its electronics;

this explains why U-233 has never been pursued for weapons beyond

proof-of-concept demonstrations." - - -

http://en.wikipedia.org/wiki/Breeder_reactor

This is why

the author is suggesting that only the "Single Fluid Converter" molten salt

reactor be built and run as a

DMSR.

________________________________________________________________________________________

The Thorium Cycle

The Thorium Cycle

(We are talking about the basic THORIUM CONVERTER reactor that makes its own radioactive

fuel and then consumes it.)

From

here on, things just get better.

Once started with a small amount of radioactive uranium or plutonium, Molten

Salt reactors will continue to run on non-radioactive thorium by first

converting the dissolved thorium into radioactive uranium-233 and then

fissioning (breaking) that atom. These two reactions will happen naturally

and simultaneously when you get things right.

Thorium is found

everywhere,

is 4 times as common as all forms of uranium combined, and, used this way in liquid form, produces 250 times as much

heat energy in a

single reactor pass as

a solid uranium fuel rod. This means thorium heat could cost

less than 1/8,000th as much as coal heat. This also means, since so little

is needed, we will never consume all the thorium available on

Planet Earth. Today, thorium is simply a waste tailing of rare earth

mining.

In Detail: How non-radioactive

thorium can power a reactor.

HERE IS HOW

NON-RADIOACTIVE 232-THORIUM IS FIRST CONVERTED INTO RADIOACTIVE 233-URANIUM (Breeding Reaction)

AND THEN IS LATER FISSIONED (Chain Reaction). BOTH REACTIONS

MAKE HEAT.

(The author

took the liberty of editing the diagram appearing in the Moir-Teller article to

make it more understandable to non-nuclear folks like himself.)

(The

original Moir-Teller diagram.)

________________________________________________________________________________________

There appears to be no practical obstacle to vastly different sizes of Molten

Salt reactors.

A more

detailed introduction by a professional writer in a hurry.

MSR - The Thorium Paradigm .pdf

A

conservative

introduction.

http://energyfromthorium.com/joomla/index.php?option=com_content&view=article&id=64&Itemid=63

An

on-line Wikipedia article:

http://en.wikipedia.org/wiki/Molten_salt_reactor

http://en.wikipedia.org/wiki/Thorium_fuel_cycle

________________________________________________________________________________________

Quick

History of Thorium-fueled and Molten Salt Reactors

Quick History of

Thorium-fueled and Molten Salt Reactors

Born in

Cold-War secrecy, this reactor type was first developed as a nuclear aircraft engine

in the 1950s by Pratt and Whitney, test-stand run successfully, given multiple rides

in a B-36 bomber to get crew shielding right. Nuclear intercontinental

bombers were abandoned as reliable, extremely accurate, and virtually impossible

to intercept intercontinental missiles were being perfected.

Interestingly, the Soviet version of the nuclear powered bomber weighed

within 5,000 pounds of our 75-ton NB-36. The idea of nuclear civilian

airplanes with their potential of crashing into a city caused the successful

X-39 dual J47 nuclear jet engine to be forgotten.

Thorium as

a weapons material was

abandoned by the U.S. military when it proved to have poor military weapons value

in every respect. After a discouraging test firing of the only atomic bomb

ever made from thorium, MET, 1955, development work on thorium as a weapons

material was ended.

http://en.wikipedia.org/wiki/Operation_Teapot

A ten

megaWatt Molten Salt Reactor was later built at Oak Ridge National

Laboratories. It ran well for about 5 years on both pure and various blends of

thorium, uranium, and plutonium.

and various blends of

thorium, uranium, and plutonium.

Solid

thorium fuel rods were used experimentally in the 1957 conventional 60 MWe "Shippingport"

reactor near Pittsburgh, PA, between 1977 and 1982.

http://en.wikipedia.org/wiki/Shippingport_Reactor (Right, Shippingport

reactor vessel.)

A 1,000

megaWatt (e) Molten Salt electricity generating unit was designed by EBASCO (a

consortium of 15 Midwest power companies) for Oak Ridge National Laboratories in

1965, and then shelved in favor of established conventional solid fuel

reactors.

The MSR

program had very poor weapons material breeding potential and was cancelled about 1974 when the government decided in favor of

funding liquid metal fast breeder reactors which could make far more, and

better, weapons

material far faster.

The liquid

metal fast breeder reactor program, in turn, was killed for nuclear proliferation

reasons in 1994 by an administration with strong anti-nuclear ties.

Czech Republic, France, China (molten salt reactor development,

large thorium deposits, small uranium deposits), India (solid thorium fuel rod

reactors, large thorium deposits), are

currently active in thorium energy research with Norway (large thorium

deposits), Japan, and Russia

looking on.

________________________________________________________________________________________

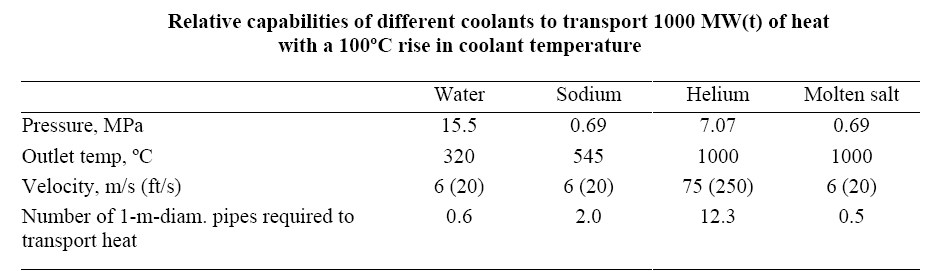

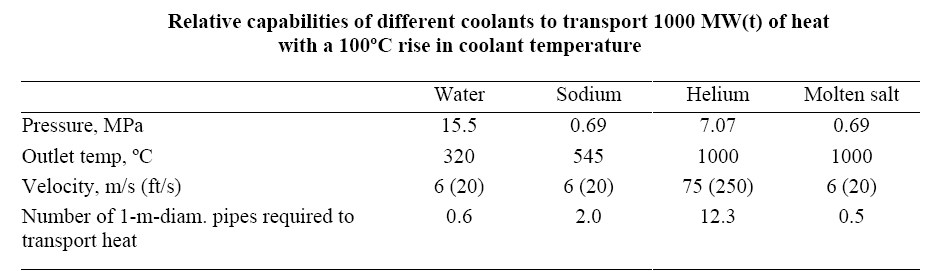

About Using Molten

Salt as a Coolant.

About Using Molten Salt as a

Coolant.

________________________________________________________________________________________

Nuclear Aircraft Engines 1946-1962

Nuclear Aircraft Engines 1946-1962

"Aircraft Nuclear Propulsion (ANP) Program",

Mid-1950s

Molten Salt Reactors (MSRs) - a type of Nuclear

Reactor

The most interesting application of molten salt

technology was the development of the Molten Salt (Nuclear) Reactor

(MSR). Originally developed to power a deep penetration bomber for

targets in the Soviet Union during the early Cold War (1946 - 1962),

it is a remarkable, yet virtually unknown reactor. Part of the problem

was the limited geographical experience of the MSR as both operating

MSRs were built only at Oak Ridge National Laboratory (ORNL), near

Knoxville, Tennessee, USA.

The first MSR was the 1954, 100-hour operation of the

Aircraft Reactor Experiment (ARE) at ORNL. Its sole purpose was to

demonstrate the then unheard of notion of operating a reactor at red

heat (~750°C; ~1,550° F) with a molten fuel and coolant consisting of

melted fluoride salts (sodium fluoride, NaF; zirconium fluoride, ZrF 4;

and UF4 [enriched in 235U]).

The second MSR was a

civilian power plant prototype, the Molten Salt Reactor Experiment

(MSRE)7.

Hugely successful, it was ignored by the US Atomic Energy Commission (US

AEC), which had decided to favor the Liquid Metal Fast Breeder Reactor (LMFBR).

The Director of ORNL, Dr.

Alvin Weinberg, pushed for the MSR, but was fired for his efforts.

The notable features of this reactor are:

● Meltdown proof

● Does not produce weapons grade plutonium

● Has inherent non-proliferation features

● Thousands of years of energy

● Simplified fuel cycle (no fuel elements nor reprocessing required)

● Its wastes are simpler and less toxic than current nuclear wastes

● Only hundreds of years of storage versus thousands for the current

wastes

● Can completely destroy military plutonium

● Can burn the existing wastes (spent fuel)!

● Higher thermal efficiencies (operates at a "Red Heat"; ~700° C [1,260°

F])

The above was written and created by

Bruce Hoglund

<bhoglund@earthlink.net.DoNotSpamMe>, © 1997

Please send me any HELPFUL comments. Responsible use is allowed as long as the

author is cited.

Above from:

MSR -

What is Molten Salt & Its Technology_ .pdf

(Right) In fact, there were

TWO nuclear aircraft engines under development at the time. Heat Transfer

Reactor Experiment - 3 (HTRE-3) is the large one above and on the left in

the small picture. It came from Pratt & Whitney. The other one,

HTRE-1

(later rebuilt as HTRE-2) was an air-direct-core-cooled General Electric design.

(Small image above from Wikipedia (click

on it for large image), large

image (above) taken by author Sept, 2010 from Idaho National Labs parking lot.)

"The US Aircraft Reactor

Experiment (ARE) was a 2.5 MW

thermal

nuclear reactor experiment designed to attain a high

power density for use

as an engine in a nuclear powered bomber. It used the molten fluoride salt

NaF-ZrF4-UF4

(53-41-6 mol%) as

fuel,

was

moderated by

beryllium oxide (BeO), used liquid

sodium as a secondary

coolant and had a peak

temperature of 860 °C. It operated for a 1000-hour cycle in 1954. It was the

first molten salt

reactor. Work on this project in the US stopped after

ICBMs made it obsolete. The designs for its engines can currently be viewed

at the

EBR-I memorial building at the

Idaho National

Laboratory." - -

http://en.wikipedia.org/wiki/Aircraft_Nuclear_Propulsion

For more information about the

airplane photos, see ASME web article:

http://www.asme.org/kb/news---articles/articles/nuclear/molten-salt-reactors

________________________________________________________________________________________

After

Nuclear Aircraft Engines

After

Nuclear Aircraft Engines

Molten-Salt

Reactor Experiment 1965 to 1969.

(Oak Ridge National Labs Photo from Kirk Sorensen's 2011 TEA talk slides.)

Notice the water-cooled pump motor. The 1,200°F reactor was so hot you

could take a photograph of it at night without a flash. Both the heat and

corrosiveness of the salt makes this a place to stay away from. EBASCO did

some unrecognized brilliant engineering and came up with a far better reactor

confinement cell design.

(Left) SHOW ME THE FIRE-HOT HEAT.

Molten salt-to-air heat exchanger running

full-blast. 1,200°F+ is the normal discharge temperature of this reactor.

It can replace most coal, natural gas, and oil fires. Molten salt reactor

experiment, Oak Ridge National

Laboratories.

Temperature Colors - 540.jpg

(Right) Assembling the graphite core of the

experimental 10

megaWatt Molten Salt Reactor (MSRE).

"The MSRE's piping, core vat and structural

components were made from

Hastelloy-N and its

moderator was a

pyrolytic graphite core. The fuel for the MSRE was

LiF-BeF2-ZrF4-UF4

(65-30-5-0.1), the graphite core

moderated it, and its secondary

coolant was

FLiBe (2LiF-BeF2),

it operated as hot as 650 °C (1,200°F) and operated for the equivalent

of about 1.5 years of full power operation."

From:

http://en.wikipedia.org/wiki/Molten-Salt_Reactor_Experiment

________________________________________________________________________________________

Costs

Molten salt is salt heated hot enough to melt and

flow like water. So a liquid reactor fueled by

thorium is called "Liquid Thorium" (at least

on this web site).

One unpleasantness

is the is the reactor's salt, FLiBeF (Flibe). While a great reactor

salt that will last forever carrying radioactive fuel dissolved in it, is toxic

(as are most salts) and also expensive. Fortunately, not a large amount is

needed to fill the reactor and the primary heat exchangers. FLiNaFKF

(Flinak) could be a secondary coolant loop salt. Some think a much cheaper

commercial heat transfer salt such as HITEC (used in solar heat collectors)

might suffice in some secondary loop designs and would certainly work in any

tertiary loops. Corrosion is addressed by using alloys such as

Hastelloy-N, with 2% titanium added to avoid long-term embrittlement due to

radiation. The operating design life would be 90 years with 30-year major

maintenance intervals.

________________________________________________________________________________________

NEWS ITEMS

Richard Houghton, March

26th, 2011 at 10:46

I wish that Mr. Gates had first seen the research already done and

already tested for 5 years at Oakridge, namely liquid fluorine thorium reactors.

This nuclear reactor uses liquid salts with dissolved thorium which is converted

to a fissile material (u233) and burned. No cooling system required, no bomb

material is possible, can be shut down and restarted in same day, uses nuclear

waste material as fuel, needs no massive containment structure, operates at

atmospheric pressure, needs no water to cool or create steam. And it has been

proven by our own nuclear program and run for 5 years. They would run it during

the week and turn it off for the weekend and restart it on Monday. Will cost

half of what a conventional nuke plant costs. Is scalable for large plants and

for industrial business use.

Check out thoriumalliance.org for more information.

Bill Gate's Traveling Wave

Reactor: How do you turn it on and off for maintenance? How do you

turn it up and down for load following? How hot is it? Is there some

web site where these questions are answered?

I wonder about the neutron

spectrum, and whether the reactivity control is accomplished by a combination of

Doppler and density (as a function of temperature). This seems to be an

interesting exercise on paper, but I'm highly skeptical with respect to

practicality.

I'm curious about the transport of fission gases (Xe, Kr) and volatiles to the

plenum volume, and the conduction of heat to the liquid metal coolant. -

Astronuc

Thorium Another sign it is the coming nuclear fuel .pdf

![]() ran for several years on solid thorium.

ran for several years on solid thorium.

and various blends of

thorium, uranium, and plutonium.

and various blends of

thorium, uranium, and plutonium.