thoriumapplications

.com

to

Home Page  Site Map

Endless

Clean Energy

Site Map

Endless

Clean Energy

MOLTEN

SALT REACTORS, Chapter

9, Page 2:

Fast-Tracking The Next Prototype MSR On A Slow Boat From China

< 1 Page

3 >

Prototype Testing Barge

Fast-tracking MSR development on a slow boat from China.

The

"Proof-of-Performance" EBASCO Reactor Cell Barge

(Fast-Tracking development in the olden days

of slide-rules was more cavalier. Build it, then test run it from behind a nearby wall.

If it doesn't blow up, you're in.)

(Have you noticed we haven't put anyone on the Moon since we've become addicted

to computers?)

Note: A single fluid molten salt reactor

emulator might be possible substituting the graphite rods with steam tubes

heated by a package boiler.

The Chinese have a formal thorium MSR program at the

Chinese Academy of Sciences University (their equivalent to MIT).

Hire Dr. D. L. as consultant, K. S. as engineer, show up at CAS with a barge

full of cash and a pad of purchase orders.

Let me be completely up-front about

this particular brainstorm.

If the United States government wasn't so nuclear dysfunctional, this scheme

would never have occurred to me.

By building a 100 megaWatt (thermal) size development reactor (about 10 times

the size of ORNL's experimental Molten Salt Reactor) in a full-size EBASCO

confinement cell on a barge, it can be built legally anywhere in the world.

Then it can be taken to some extremely isolated unpopulated island owned by some

nuclear-friendly small country (there are over 200 countries), fueled with uranium-235 (for simplicity) and run

through whatever tests are dreamed up. Something like operating a ship

under a "Flag of Convenience."

Even if you plan to never have fissile material

within U.S. jurisdictions, be certain that whatever you do meets

10 CFR

PART 810.3

Ch. III (1–1–08 or later edition). Get paperwork that confirms that you

have reviewed and confirmed all your fissile material plans with the proper

authorities of U.S., whatever foreign jurisdictions you will be working with,

and the IAEA. Nobody likes people who are being secretive about their

fissile materials activities.

Molten Salt Reactor Simulator

A molten salt reactor simulator, using electric Calrods for core heat instead of

nuclear fuel, done in the spirit of NuScale and mPower, should be the first

order of business. Picking up where the ORNL Molten Salt Experiment

reactor left off, but of the same size and using modern materials, with both

primary and secondary cooling loops.

http://www.energyfromthorium.com/pdf/NAT_MSREexperience.pdf Experience

with the Molten-Salt Reactor experiment. Haubenrich and Engel, 19 page pdf

http://energyfromthorium.com/forum/download/file.php?id=988&sid...

Stability Analysis of the Molten Salt Reactor Experiment. SJBall, TWKerlin

51 page pdf

Barge -

Sub-Seabed Waste Solution - 96.10.pdf If the remote testing of

the prototype reactor mounted on the barge goes terribly wrong.

Barge - Seabed Disposal of High-level Radioactive Waste .pdf If the

remote testing of the prototype reactor mounted on the barge goes terribly

wrong.

MSR - Denatured -

CNSLeBlanc2010revised.pdf Since the barge will be on the high seas,

there will always be the remote possibility it will be stolen by pirates or

environmentalists. By using more expensive denatured fuel instead of

thorium for the tests, if the barge is taken the fuel will be virtually useless

to even advanced countries.

100 megaWatt (thermal) Prototype Reactor

With today's space-age telemetry technology,

a distant and upwind "Mother Ship" could manipulate and monitor the unmanned reactor far

better than the original 1950's and 1960's "Hands On" tests that were done so

long ago on the original MSR reactors at Oak Ridge National Laboratories.

After it is known for certain all is safe under all conditions, it is suggested

a "Galena-like" offer be made to one of the host country's isolated populated

islands to supply free electricity from the reactor barge for the next 10 to 30

years for long-term operational observations. The 20 megaWatt (electrical)

Stirling turbogenerator is a substantial amount of electricity for some small

town and would make an excellent long-term fluctuating test load for the

reactor. Real-time

monitoring (and

supervised

circuit shut-down controls)

via satellite links would be easy.

This will be the molten salt reactor's modern

"Pathfinder."

The first time you build something is when

you make completely detailed plans - down to the last screw and wire connector.

Errors caught in the planning stage are usually 1,000 times cheaper to fix than errors

caught in the field.

Systems built to nuclear navy standards are always more rugged than when built to

land only standards, i.e., corrosion, flexing, thermal stress, etc.

This particular EBASCO cell barge will be isolated for long periods of time

during proof-of-performance testing and so must

provide oil platform-like living quarters.

http://energyfromthorium.com/2011/12/27/bonometti-teac3/

Lessons Learned Lecture:

Lesson Learned # 1

Lesson Learned # 2

Lesson Learned # 3

Lesson Learned # 4

Lesson Learned # 5

Lesson Learned # 6

Lesson Learned # 7

Lesson

Learned # 8

Lesson Learned # 9

Specifications

All electrical 220V, 50 Hz.

Ancillary Equipment

Designing, Building, Testing

Designing

The Panamax Ocean-Going Barge

100' w, 300' l, 40' h 30,000 sq ft per deck, 70,000 total

Barge Equipment Room (U)

Bilge Pump Panel (BER)

Bilge Pumps (L)

Bilge Pump Disconnects (L)

Barge Lighting Panel (BER)

Barge Emergency Electrical Panel (BER)

Float Switch Panel (BER)

Rooms

Control Room (U)

Electrical Room (U)

Instrumentation Room (U)

Maintenance Shop (U)

Toilet, Shower, Locker Room (2) (U)

Lounge - Conference Room (U)

Sleeping Quarters (4)

Office Room (U)

Diesel Engine Room (L)

Salt Storage Room (L)

Thorium Storage Room (L)

General Storage Rooms (U)

Diesel Fuel Storage Room (L)

Lift Shaft

Environmental Systems

Heating

Cooling

Hot Room (U)

Radiation Proof Viewer

Manipulator

Fuel Blender

Reactor Confinement Cell for up to 1,000 mW electrical or 2,500 mW thermal

Cell Walls and Roof

Roof Penetration Sleeves

Wall Penetration Sleeves

Reactors, 100 mW Thermal, 1,000 mW electrical

Reactor Tank

Graphite Core

http://en.wikipedia.org/wiki/Nuclear_graphite Conventional Graphite is

about $15 per pound.

Control Rod System

Package Heater - Diesel Fuel

Heat Exchangers

Primary to Secondary (2)

Idle Heat Exchanger

Fuel Salt Drain Tank Heat Exchanger coolant:

http://www.radcoind.com/mk1prop.html

http://www.dow.com/heattrans/prod/synthetic/syltherm.htm

Confinement Cell Passive Cooling System

Circulation Pumps

Primary Cooling Loop (Fuel Salt) Pumps (2)

Secondary Cooling Loop (Clear Salt) (1)

Fission Gas Handler

Drain Tanks (L)

Freeze Plug System

Drain Tank Pump System

Diesel Fired Package Heaters for Drain Tanks

Fuel Salt Drain Tank

Clear Salt Drain Tank

Leak Tank

Electrical System

Circulating Pump Feeder Panel

Circulating Pump Disconnects

Nichrome Tracing System Panel

Emergency Electrical Panel

Lighting Panel

Diesel Generators (2)

Diesel Fuel Storage Tank

Instrumentation

Local Control Panel

Thermocouples

Telemetry

Communication Systems

Telephone

Radio

Satellite Link

PA System

Intercom

Life Safety Systems

Fire Alarm

Sprinkler System

Fire Pumps

Life Raft (4)

Helicopter Pad

Inerting System (L)

Pressure Regulators (2)

Pressure Sensors (5)

Gas Storage Tanks (2)

Water System

Reverse Osmosis Desalinator

Potable Water Storage Tank

Pressurization Pump and Tank

Sewage Holding Tank

Refrigerated Drinking Fountain

Galley

Range

Food Storage Room

Freezer Locker

Refrigerator

Supplies (L) Make sure you know exactly how

everything was made, everything that ever touched the equipment, pipes, and storage

tanks.

Fuel Salt

Secondary Salt or Clear Salt

Thorium

Externally Heated Turbine (Top Deck)

Control Panel (Control Room)

Transmission Instrument Panel (Control Room)

Main Transmission Breaker (Top Deck)

Cost Estimate

Construction

Equipment Suppliers

Testing

Reactor Simulation Boiler

Operating tests at uninhabited remote South Pacific island

Post Testing Trial Service

Russian Nuclear

Barges

________________________________________________________________________________________

Specifications

(Following copied from "Restarting

America's Liquid Reactor Technology" page.)

(Below) It

strikes me that the next logical step up might

be a 100 megaWatt

(thermal) unit in EBASCO's 2,500 megaWatt (thermal) confinement cell with 2

fuel salt circulating pumps and 2 100 megaWatt (thermal) heat exchangers, each with its

own clear salt circulating pump and independent heat sink.

The oversize cell will give us a break in the heat department and dual 100 mWt pump/heat

exchanger systems will give us 100% redundancy in cooling capabilities.

Heat sinking is one thing you don't cheap out on when fooling around with

nuclear reactors.

The turbine's 25MVA generator should be 2Pole, 50Hz, 6.3KV.

The barge generally should be 220 Volts, 50Hz.

Ancillary Equipment

Drain tank heaters would

have to be propane gas.

There would have to be a pair of fairly large diesel generators aboard for

the circulating pumps, etc.

The two dummy load water heat exchangers would not need to be made of

Hastelloy-N. The MSRE consumed 200,000 pounds of Hastelloy-N, this

project should come in at well below 300,000 pounds.

The test load combustion turbine would be a 25 megaWatt unit with its

combustors replaced with Hastelloy-N molten salt heat exchangers.

Here's a company who is advertising to do the job.

http://www.cpsag.ch/power-generation/advanced-product-development/conversion-to-external-firing

This Australian company is making small external combustion turbines:

http://www.btola.com/

________________________________________________________________________________________

Designing, building

and testing the molten salt reactor prototype.

Designing

Below is the reactor-barge, to the right is the

70 foot by 50 foot high

1,000 megaWatt molten salt converter reactor (tank in center of the cylindrical

confinement cell, surrounded by 4 fuel salt circulating pumps - 2 shown, motors

in the cool above the cell's ceiling - and 4 fuel salt-to-clear salt heat

exchangers) as described in the report above.

While the author has been a control system project

engineer for most of his career, he has never taken on anything close to this.

Tempering the Author's thinking is a whiff of

"Cargo Cult" enthusiasm often present in

presentations by thorium advocates.

Over the years I've seen this same sort of enthusiasm cause even IBM to stumble.

It ain't pretty when you are a member of the project team.

The hard fact is that only one clear-cut molten salt

reactor has ever been built (an 8 megaWatt (thermal) air-cooled unit that was powered for a short while on thorium) and run in the United States. It never produced a single

Watt of electricity. But it also never produced any nasty surprises over

its 5-year run with both uranium and thorium as fuels.

MSRE experience report (pdf)

While the EBASCO report was done by "A" list

engineering companies under contract to Oak Ridge Laboratories, the fact is the

plant was never built so we'll never know for sure if they got it "right

enough."

The heat and corrosiveness of this reactor is

daunting. At 1,300°F it runs so hot you can take a photograph of it in the

dark without a flash. Thorium, which gets converted into

uranium-233, can have one of its neutrons knocked off later, producing

uranium-232, which then produces an especially dangerous form of gamma radiation

when it decays.

The Oak Ridge National Laboratories 1965 to 1970

"Molten Salt Reactor Experiment" reactor was 8 megaWatts (thermal). The EBASCO design shown above is for a 2,500 megaWatt

(thermal), 1,000 megaWatt (electrical)

power station. A 312-fold jump in thermal power beyond what is proven, far

too large to be attempted in a single step. The proposed "Proof of

Performance Prototype" is 100 megaWatts (thermal), a twelve-fold increase in

size. If there are no nasty surprises in the prototype, the ten-fold step

up from the prototype to EBASCO's design would be reasonable.

http://www.flowserve.com/Products/Pumps/Vertical/Wet-Pit/Molten-Salt-VTP-Pump%2Cen_US

(Right) Decide on the power you want and the

chart at right shows the diameter the core needs to to be to last the number of

years you want power (up to 30 years max). (From Moir-Teller)

- - Then cut the "I" beams in the reactor cell to fit.

The prototype molten salt reactor would have a

30-year core diameter of about 3 meters (9 1/4 feet). The inside diameter

of the EBASCO confinement cell is about 66 feet so there will be plenty of elbow

room for the two heat exchangers and associated pumps and piping.

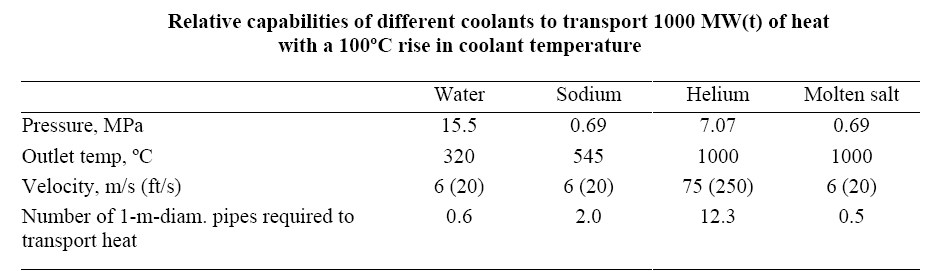

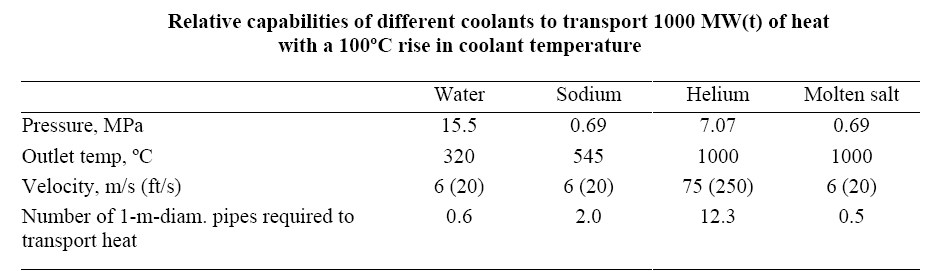

(Below) You can compute the size and flow rates of

the cooling loops from the table below. NOTE: The table is for 1,000

megaWatts THERMAL !

(From Forsberg)

________________________________________________________________________________________

The Panamax Ocean-Going Barge

Panamax Ocean-Going Barge

PANAMAX: The maximum

dimensions allowed for a ship transiting the Panama canal are:

- Length: 965 ft (294.13 m)

- Beam (width): 106 ft

(32.31 m)

- Draft: 39.5 ft (12.04 m) in

tropical fresh water (the salinity and temperature of water

affect its density, and hence how deep a ship will float in

the water)

- Air draft: 190 ft (57.91 m)

measured from the waterline to the vessel's highest point

A Panamax cargo ship would

typically have a DWT of 60,000 to 80,000 tonnes and a maximum cargo

intake of 52,500 tonnes.

Smaller

typical

Seagoing Barge: 150' x 40' x 10' 965 Short Tons.

Larger typical Seagoing Barge:

210' x 60' x 13' 6" 3,050 Short Tons.

http://www.mcdonoughmarine.com/index.htm

U.S. River Barge:

A typical large river barge measures 195

by 35 feet (59.4 m × 10.6 m), and can carry up to 1,500 short

tons of cargo. 9 feet of draft is typical.

It's going to

have to be Panamax wide. The EBASCO reactor confinement cell is 70

feet Diameter by 50 feet high. The reactor tank is

about 29.9 feet in diameter, 30.8 feet tank height. That makes it a candidate for the

106' wide, 201' long, 13.5' draft,

3,050 short ton, larger seagoing barge. This would give about 15 feet of

clearance between the barge's 3 foot thick walls and the outside of the cell's

wall.

http://www.atomicinsights.com/aug96/Conventional.html Power Barges:

Tools for Progress

Saint Lawrence Seaway

Seawaymax

(From various Wikipedia articles.)

The southern

terminus of the Welland Canal on Lake Erie, located at Port Colborne, is 99.5

meters (326.5 feet) higher than the northern terminus of the Canal at Port

Weller on Lake Ontario. This canal includes eight ship locks, each of which is

24.4 meters (80 feet) wide by 233.5 meters (766 feet) long.

The Poe Lock, re-built in 1968, after

the Saint Lawrence Seaway had opened. It is 1,200 feet (366 m) long,

110 feet (34 m) wide, and 32 feet (10 m) deep. It can take ships

carrying 72,000 tons of cargo. The Poe is the only lock that can handle

the large lakers used on the upper lakes. The original Poe Lock was

engineered by Orlando Poe and, at 800 feet long and 100 feet wide (244 x

30 m), was the largest in the world when completed in 1896.

The size of vessels that can

traverse the seaway is limited by the size of locks. Locks on

the St. Lawrence and on the Welland Canal are 766 ft (233.5 m)

long, 80 ft (24.4 m) wide, and 30 ft (9.14 m) deep. The maximum

allowed vessel size is slightly smaller: 740 ft (225.6 m) long,

78 ft (23.8 m) wide, and 26.5 ft (8.1 m) deep; many vessels

designed for use on the Great Lakes following the opening of the

seaway were built to the maximum size permissible by the locks,

known informally as Seawaymax or Seaway-Max. Large vessels of

the lake freighter fleet are built on the lakes and cannot

travel downstream beyond the Welland Canal. On the remaining

Great Lakes, these ships are constrained only by the largest

lock on the Great Lakes Waterway, the Poe Lock at the Soo Locks,

which is 1,200 ft (365.8 m) long, 110 ft (33.5 m) wide and 32 ft

(9.8 m) deep.A vessel's

draft is another obstacle to passage on the seaway, particularly

in connecting waterways such as the St. Lawrence River. The

depth in the channels of the seaway is 41 ft (12.5 m)

(Panamax-depth) downstream of Quebec City, 35 ft (10.7 m)

between Quebec City and Deschaillons, 37 ft (11.3 m) to

Montreal, and 27 ft (8.2 m) upstream of Montreal. Channel depths

and limited lock sizes mean that only 10% of ocean-going ships

can traverse the entire seaway.

Mississippi Barges

What is the size of a barge?

The standard barge is 195 feet long, 35 feet wide, and

can be used to a 9-foot draft. Its capacity is 1500 tons. Some

of the newer barges today are 290 feet by 50 feet, double

the capacity of earlier barges.

________________________________________________________________________________________

Rooms

Control Room

Electrical Room

Instrumentation Room

Maintenance Shop

Toilet, Shower, Locker Room

Lounge - Conference Room

Office Room

Diesel Engine Room

Salt Storage Room

Thorium Storage Room

General Storage Rooms

Diesel Fuel Storage Room

________________________________________________________________________________________

Supplies

The Salts

The Salts are fluorides of light metals - lithium

and beryllium - commonly called

FLiBe (2LiF-BeF2).

http://www.dow.com/heattrans/prod/synthetic/dowtherm.htm Dowtherm "A"

(15 to 400°C) might be considered a test stand-in for FLiBe for early heat exchanger experiments.

FLiBe is a mixture of

lithium fluoride (LiF) and

beryllium fluoride (BeF2). As a

molten salt it is proposed as a

nuclear reactor coolant, and two different mixtures

were used in the

Molten-Salt Reactor Experiment.

1.

The 2:1 mixture with proportions Li2BeF4

has a melting point of 459°C (858°F), a boiling point of

1430°C (2610°F), and a density of 1.94 g/cm3. Its

heat capacity is 4540 kJ/m3, which is

similar to that of water, more than four times that of

sodium, and more than 200 times that of helium (at

typical reactor conditions).

2. The

eutectic mixture is slightly greater than 50% BeF2

and has a melting point of 360°C (680°F). -

http://en.wikipedia.org/wiki/FLiBe

http://en.wikipedia.org/wiki/Heat_capacity

The fuel for the MSRE was

LiF-BeF2-ZrF4-UF4

(65-30-5-0.1), the graphite core moderated it, and its secondary coolant was

FLiBe (2LiF-BeF2), it operated as hot as 650 °C (1,200°F) and

operated for the equivalent of about 1.5 years of full power operation."

http://en.wikipedia.org/wiki/FLiBe

http://en.wikipedia.org/wiki/Lithium_fluoride

http://en.wikipedia.org/wiki/Beryllium_fluoride

http://en.wikipedia.org/wiki/Zirconium_fluoride

http://en.wikipedia.org/wiki/Uranium_tetrafluoride

In the

Molten-Salt Reactor Experiment it served as

solvent for the

fissile and

fertile material fluoride salts, as well as

moderator and coolant. Different mixtures were used in

the two cooling circuits.

Some other designs

(sometimes called molten-salt cooled reactors) use it as

coolant, but have conventional solid

nuclear fuel (i.e., TRISO pebbles) instead of

dissolving it in the molten salt.

ORNL has 2400

kg of

Flibe. He estimates that

Flibe costs somewhere

between $45 and $125 per kg.

(

www.fusion.ucla.edu/apex/meeting5/summary5.pdf-

)

Another, commercially available, heat transfer salt

is "HITEC." It was suggested for use in the third loop of the

EBASCO-designed supercritical steam power plant.

Several issues

touched on in the LFTR forum's cost thread invite Nuclear Green

posts, but one by Chemical Engineer Kim L Johnson

(

http://fluorine.sites.acs.org/apps/profile/58116851/ )

MSR - Johnson, Kim L - Fluorine Chemistry - 760.jpg

is down right pregnant. Johnson writes,

"I'm

a chemical engineer who has been working to develop industrial

Fluorides for many years and have assembled lots of online

documentation for the benefit of Lftr and the like.

If you have any significant interest in Fluorides, structural

materials for Fs and in which forms of whatever elements are

best for the Lftr bath & containment, I would be happy to send

you lots of link. Sadly however, I can no longer post

important details Freely. Serious Foreign competition

could very well, in a few years' time, leave the US so far

behind in our own Fluoride-Energy tech we'd never recover

economically. Fortunately, the very successful efforts of

TEA & other "T Com" leaders -- fruit we shall soon see in the

Senate & elsewhere -- should shortly enable guys like you,

(hopefully) Lars, and many others to develop Thorium-enabled

technologies full time (*just* getting off the phone with this

effort's champion) !"

via NuclearGreen

- Charles Barton 9/2/11

The third part of my interview Q&A with Sherrell Green

focused on questions concerning the future of nuclear

technology. My father had been a pioneer in research on Liquid

Chloride Reactor technology in the 1950's. Sherrell Greene

mention LCR development during out preinterview, so I wanted to

ask him some follow up questions. The LCR is a potential

competitor to the Liquid Metal Fast Breeder Reactor, but it is

not clear if itsadvantages would out wight its potential costs.

Sherrell notes that,

The environment

in today’s nuclear energy enterprise is hostile to innovation.

This is undoubtedly the case, and the consequence of our

unwillingness to take risks on new concepts in nuclear power are

ominous. for our country are ominous. Continuing a business as

usual pattern is likely to bring national economic and

environmental failure, but it is not clear what it is we should

be doing.

34. Do any Liquid Chloride Salt formulas hold potential

advantages in comparison to Flibe (The lithium fluoride (LiF)

and beryllium fluoride (BeF2) mixture, often referred to as the

preferred carrier/coolant salt formula for MSRs?

Most of the chloride-based salts

don’t perform well in the thermal spectrum. Corrosion management

is more demanding than the fluoride salts. LiF-BeF2 (FLiBe)

mixtures are very attractive from the nuclear, thermal,

chemical, and thermo-mechanical standpoint. But with you have a

tritium production issue, a lithium enrichment cost issue, and a

beryllium occupational exposure issue to deal with. All of that

drives up the cost. George Flanagan and David Holcomb at ORNL

have recently evaluated some of these issues. They conducted an

initial screening of LCR salt options, and developed a pre-pre-

conceptual concept for a LCR. MIT and a few others have also

done work in this area.

35. Do any Liquid Chloride

Salt formulas have the potential of being technically

competitive with Flibe, but at a lower cost?

Again, I think you will want to

consider chloride salts for harder-spectrum systems. So it’s a

different application. That’s said, I don’t think we know enough

to answer the question. I am pessimistic there is a chloride

salt that can match FLiBe from an integrated performance

perspective.

via NuclearGreen

- Charles Barton

Fuel Salt

Secondary Salt or Clear Salt

(No tertiary salt such as HITEC should be needed in

this application.)

Thorium

________________________________________________________________________________________

Externally Heated Turbine

The table above gives an idea as to

the range of temperature expected from non-intercooled,

non-reheat, single shaft turbine engines. The centrifugal

compressor has an isentropic efficiency of 80% and a pressure

ratio of 4 to 1 while the axial-flow turbine has an isentropic

efficiency of 85% and a pressure ratio of 3.8 to 1. Ambient air

temperature is specified at 32-degrees C or 90-degrees while the

compressor outlet temperature has been calculated at 424-degrees

F. The part-load fan and combustion induction fan are specified at

pressure ratios of up to 1.1 to 1.

The range of combustion temperatures

reflects the range of fuel being used, from gasified biomass

having high moisture content to anthracite coal. Gasified coal

typically combusts near 2100-deg F.

The X211, also known

as the J87, was a nuclear-powered turbojet engine

designed to power the proposed WS-125 long-range bomber.

The program was started in 1955 in conjunction with

Convair for a joint engine/airframe proposal for the

WS-125. It was one of two nuclear-powered gas turbine

projects undertaken by GE, the other one being the X39

project.The X211

was a relatively large turbojet engine of straight

conventional layout, save for the combustion chamber

being replaced with a heat exchanger. It featured

variable-stator compressors and an afterburner. A single

nuclear reactor was intended to supply heat to two X211

engines.

http://www.poweronsite.org/ Cogeneration

Association

http://www.energysolutionscenter.org/ Gas

Association - GE has some interesting turbines -

organic, etc.

http://www.poweronsite.org/Tutorial/CombTurbine.htm#Overview

Good paper, good source.

http://www.ecotera.com/tec.htm External

combustion turbines.

http://www.btola.com/

Creative Power Solutions

- Brent Gregory, President

Title

President at Creative Power Solutions

Demographic info

Phoenix, Arizona Area

|

Utilities

Current: Partner at Creative Power Solutions, President

at Creative Power Solutions (USA) Past: Consulting

at Siemens Energy, Senior Staff Engineer at GE Energy,

Manager at GE Education: Rolls-Royce - Engineering

Apprenticeship Summary: Engineering Manager

Creative Power

Solutions (Usa),

Inc in

Scottsdale, AZ

is a private

company

categorized

under Turbines

Manufacturers.

Current

estimates show

this company has

an annual

revenue of

$470,000 and

employs a staff

of approximately

3. Companies

like Creative

Power Solutions

(Usa), Inc

usually offer:

Olympian

Generator Sets,

Motor Generator

Sets, Capstone

Turbine, Steam

Turbine

Generator Set

and The Partisan

Turbine.

________________________________________________________________________________________

Cost Estimate

Order of Magnitude Cost Estimate: The author knows of several

consulting engineering firms that may be

willing to take on such a task and several nuclear energy consultants that may

be willing to share their thorium-fueled Molten Salt Reactor knowledge. Neither are inexpensive, but this is the moment where many

securable innovative ideas occur. In light of the unique international

nature of this endeavor, both the engineers and the nuclear consultants - along

with their previous works - will have to be extensively vetted. Corrosion

is still a concern, so expertise in corrosion would be a plus.

Scope:

As a preliminary engineering investigation for

the coal2nuclear reactor barge concept the author

is advocating, the reactor and steam generators from this 1962 design will be

extracted and used as rough design and preliminary cost

templates.

Once this is complete, a realistic preliminary cost

estimate for building and installing a coal2nuclear

conversion reactor can be made.

The new engineering study and preliminary drawings

would be divided into six major

sections:

1. The barge-mounted reactor and first salt heat exchanger.

2. The second salt heat exchanger and its building.

3. The steam generators and their building.

4. The barge's radiation confinement

slab system.

5.

The barge itself.

6. A materials list covering the initial load of salt and fuel materials.

Changes in devices, materials, and their procurement will produce a modern

Model "T" reactor that will be the reactor envisioned in

Dr. Ralph Moir and Dr. Edward Teller's

paper.

Connected to an existing superheated steam power

plant, it will be a coal2nuclear conversion.

Model "T" reactor has an estimate for the complete plant.

Table N . l . 1000 Mwe Molten Salt Converter

(Begins on pdf page 292)

Reactor Plant -Estimate of Capital Investment

ONE (1) 2500 MWt MOLTEN SALT REACTOR

ONE (1) 1000 MWe REHEAT TURBINE GENERATOR

UNIT C.C.6F 40" L.S.B.

(2400 Psi. - 1000°F - 1000°F)

(Prices as of 11-1-62 and Based on a 40 Hour Work Week)

TOTAL CAPITAL INVESTMENT $148,875,600

(on pdf page 327)

To get some idea of what this sort of equipment might cost

in 2011 dollars, there was a 1,000 KW diesel generator quoted at $110,000 on pdf

page 326. On the web, GoPower.com is offering a new 1000 KW Cummins

Powered Generator Power Module, Model OC1000 PM for $260,000.

Extracting the relevant components from the Model "T"

reactor

document.

Major components:

1. The barge-mounted reactor and its fueling

system

2. First salt heat exchangers - 4

3. Second salt heat exchanger and its building.

4. Feedwater pre-heater

5. Combined evaporator and steam superheater

6. Steam reheater

7. Dump Tanks and package boiler salt heaters

8. Barge and its radiation confinement slab system

Dump tank shields. What about adding fixed boron rods

to the dump tanks to quench decay heat?

9. Steam Generator Building

Major Factory Infrastructure Components:

1. Fuel salt preparation facility

Estimated capital costs for only the coal2nuclear

equipment from the 1972 report:

Structures & Improvements

Grounds - p295

501,500

Turbine Building - p299

2,342,600

Waste Disposal Building - p301 165,950

Misc. Structures - p301

24,500

Reactor Plant Building - p304 2,932,400

Stacks: Concrete Chimney - p304

31,000

Reactor Equipment

Reactor Equipment - p306

8,823,300

Heat Transfer Systems - p309

23,609,700

Fuel Handling and Storage - p310

1,517,200

Radioactive Waste Treatment and disposal - p311

361,150

Instrumentation and Controls - p312

1,100,000

Other Reactor Plant Equipment - p315

3,048,500

Discussion:

The United Nations (UN),

http://www.un.org/en/index.shtml,

is biased toward helping the poorest countries in every way they can.

The United Nations, through the International Panel on Climate Change (IPCC)

http://www.ipcc.ch/, is doing everything it can to persuade countries

to cease the production and emission of greenhouse gasses, most notably carbon

dioxide. These are the entities the author hopes to help and regards them

as potential sources of guidance.

The International Atomic Energy Agency (IAEA),

http://www.iaea.org/,

a subdivision of the United Nations, has

become the world's dominant international nuclear regulatory agency (largely as

result of the world not wanting another Chernobyl). They have become the

de facto Nuclear Regulatory Commission for the world's 225 countries and are

establishing a protocol to enable non-nuclear countries to take advantage of

nuclear medicine, nuclear electricity, and nuclear desalination.

Try to form a relationship with

http://www.hyperionpowergeneration.com/ . Not a competitor in this

power area, but certainly a U.S. nuclear innovator in foreign markets that also

has experience working seriously with the U.S. Nuclear Regulatory Commission.

Remain mindful you are doing this to make

money, not save money.

________________________________________________________________________________________

Construction

It is unlikely the reactor-barge would be built in

the United States. China has a formal thorium-fueled molten salt reactor

program in place now and would be very likely to want to participate in the

development of this prototype to learn the new construction and operational

details first.

Concrete Reactor Cell

http://en.wikipedia.org/wiki/Properties_of_concrete

Concrete Barge

http://www.precastdesign.com/projects/platforms-barges.php Yee

Precast Design Group Ltd., Honolulu, Singapore

Dr. Alfred A Yee, P.E., Director, PRECAST DESIGN

CONSULTANTS PTE. LTD., 315 Alexandra Road, #04-07 Sime Darby Business Centre,

Singapore 159944,

+65 6735 8884 t, +65 6736 1077 f,

alyee.sg@precastdesign.com

President, YEE PRECAST DESIGN GROUP LTD., 1217 Palolo Avenue, Honolulu, HI 96816

U.S.A., +1 808 733 8686 t, +1 808 737 1808 f

alyee@precastdesign.com

www.precastdesign.com

________________________________________________________________________________________

Equipment Suppliers

http://www.qnpower.com/index.aspx

Chinese company that looks to be able to

build the entire EBASCO reactor cell. They do steam, but not gas,

turbines.

http://www.qnpower.com/tech.aspx?id=477 Check out their shop floor.

http://www.bechtel.com/

Having a long history of nuclear plant engineering and construction, they are

currently partnered with B&W's mPower Small Modular Reactor (SMR) power plant and

can certainly provide any heavy lifting.

http://www.babcock.com/

A nuclear equipment builder, Babcock & Wilcox is as good a source of heat exchangers and steam generators as you can find.

http://www.sargentlundy.com/ One of the world's best.

http://www.kiewit.com/districts/kiewit-power/overview.aspx Kiewit is

currently partnering with NuScale Power, a small modular reactor (SMR) company.

http://www.shawgrp.com/markets/powersvcs/nuclearpower Shaw Group.

http://www.cammell-laird.com/

British shipbuilder interested in building nuclear modules.

http://www.nuvia.co.uk/ Cammell-Laird's

nuclear partner. Could make a good partner since they are non-U.S.

________________________________________________________________________________________

Testing

Why only a 12 times scale-up of the Molten Salt

Reactor Experiment reactor - and spend so much effort to test it in the middle of

nowhere - when EBASCO was looking at a 312 times scale up to be built and first

run in the populated Midwest of the United States?. Simple, as an old

engineer I know there are many things I do not know I don't know. A 12

times scale up is an order of magnitude. If there are things to worry

about I'd rather find out with a 12 times scale up than a 312 times scale up.

The fact the reactor is mounted on an ocean-going

barge opens up a new paradigm for nuclear reactor testing. The uninhabited

far Southern Hemisphere comes to mind as a place where suitable and extremely

remote uninhabited islands are available.

The author is a control systems engineer and is

looking forward to going hog-wild with remote telemetry systems so no one needs

to be within several hundred miles the the first time the key is turned.

As a model for modern reactor as done by Americans

testing we have both NuScale's 45 megaWatt Small Modular Reactor

and Babcock & Wilcox's 125 megaWatt "mPower" SMR unit.

(SMRs have been defined by the Nuclear Regulatory Commission as nuclear reactors

300 megaWatt (e) or smaller.) Both are smaller versions of conventional

reactors with a slew of new safety and convenience features. They both run

on small, half-length versions of standard reactor fuel rod bundles so the

nucleonics are extremely well-known. The modern passive safety features were not so well known so

both companies built 1/3 scale models (I think) with electrical heating rods

substituting for the radioactive fuel rods. B&W's scale model reactor is

still under construction.

http://www.nuscalepower.com/

http://www.babcock.com/products/modular_nuclear/

NuScale completed their test prototype several years

ago. They then did everything bad they could think of and watched how the

reactor behaved. As far as I know, it passed with flying colors. As

an engineer, I must say I admire the NuScale folks. The reactor has a

North-West Coast

design flavor and looks like everyone involved were tree-hugging greens. It has

to be the safest conventional reactor in the world. The bad news is that,

while about the same size as B&W's mPower, the NuScale produces only about 1/3

as much power and probably will cost 2/3 as much. NuScale are newbies in

the reactor business, B&W, on the other hand, have, in association with

Westinghouse, produced most of our small military reactors for more than 50

years. It is interesting to note that Westinghouse recently announced its

own SMR that looks quite a bit like the other two and has some of the safety

features of both.

http://www.westinghousenuclear.com/smr/index.htm

The molten salt Proof-of-Performance prototype reactor in this

web site is a totally different animal from conventional water-cooled reactors

and its nucleonics, while prototyped a couple of times and studied sporadically

by several countries over the last 40 years, is virtually unknown when it comes

to doing a year-in, year-out workhorse task like making electricity.

________________________________________________________________________________________

Post-Testing Trial Service

This idea came from Toshiba Electric. Toshiba

developed a small fast-neutron reactor they call the 4S. It comes in 10

and 50 megaWatt (e) sizes and is designed to run unattended for 30 years.

The 4S is designed to be installed in a 90 foot deep silo and be removed and

returned by barge to Japan for refueling after 30 years. Toshiba has

offered to provide Galena, Alaska, with a 10 megaWatt unit for free for thirty

years. As it so happens, the molten salt reactor in the reactor barge is

supposed to go 30 years between servicing.

http://en.wikipedia.org/wiki/Toshiba_4S

http://en.wikipedia.org/wiki/Galena_Nuclear_Power_Plant

Somewhere in the world there has to be a remote

isolated ice-free seaside town - large enough to have a hospital - that is currently running

on costly diesel electricity. Since the prototype barge has a 25 megaWatt

gas turbine generator mounted on it, the town could provide a realistic

long-term load

cycle regimen. This would also provide a realistic support logistics

setting.

Additional electrical switchgear would make the

town's existing diesel generation

facility available as standby and peaking capacity assuming the diesels were

equipped with 50Hz line synchronization throttles.

________________________________________________________________________________________