REACTOR BARGES

CHEAP

GASOLINE ! ![]() Map

Map

REACTOR BARGES

RELOCATED NOVEMBER 20, 2011

The

Reactor Barge Module

Panamax Barges: Tug + Barge = 900 ft, Width = 106 ft,

Draft = 37 ft, Height = 190 ft, Max Dead Weight Tonnage Cargo = 55,000 Short

Tons,

Concrete, Limestone w/Portland: Specific Gravity = 2.37, 148 pounds per cubic

foot.

Contents

of this page

1)

2)

3)

4)

5)

6)

7) Russian Nuclear Barges

News Items

Cost Estimates

Components

The Panamax barge itself

The reactor cell and hot room

The passive cooling system

The reactor vessel itself - How much power do you want?

The graphite reactor core

The control rod system

The 4 fuel salt primary cooling loop circulating pumps

The 4 primary-to-secondary cooling loop heat exchangers

The reactor idle heat exchanger

The noble gas collection system

The fuel salt processing system

The freeze plugs

The fuel salt main drain tank

The fuel salt main drain tank passive heat exchanger

The fuel salt main drain tank fission decay squelch system

The fuel salt spill holding tank

The secondary loop clear salt drain tank

Operating tests at uninhabited remote South Pacific island

(Left) FlowServ molten salt

circulation pumps are available

on the web.

(Right) Decide on the power you want and the chart at right shows the diameter the core needs to to be to last the number of years you want power (up to 30 years max). (From Moir-Teller)

Then cut the "I" beams in the reactor cell to fit.

(Below) You can compute the size and

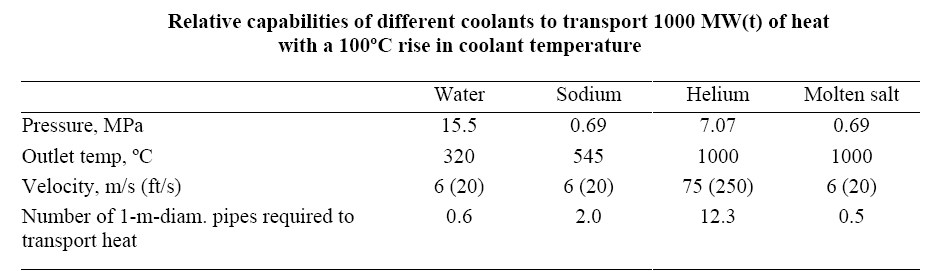

flow rates of the cooling loops from the table below. NOTE: The table is for

1,000 megaWatts THERMAL !

(From Forsberg)

________________________________________________________________________________________

If something goes bad, the reactor barge goes back to the factory. If something doesn't go bad, after 30 years the reactor goes back to the factory for either disposal or refurbishing, refueling, and reuse. The use of molten salt to transfer heat is commonplace in both industry and solar heat collection and storage systems, the use of molten salt as a carrier of dissolved nuclear fuel is not, but is a very good idea since certain salts are virtually immune to the damaging effects of the intense neutron radiation typically found in reactors. - - Jim Holm

About the above sketch:

What YOU are looking at. In 1972 EBASCO designed a 1,000 megaWatt molten salt reactor powered electricity generating plant for a consortium of 15 mid-west electricity utilities. It was never built. The drawing above shows the 70 foot in diameter, 50 foot high reactor cell EBASCO designed (their isometric sketch) surrounded by a modern passive air cooling system as it would look installed in a Panamax concrete ocean-going barge with 3 foot thick walls to contain the reactor's radiation.

Unbelievably simple and non-precision as a cooking utensil, the inexpensive self-controlling molten salt reactor shown above is basically an unpressurized tub full of melted salt and graphite rods plus 4 circulation pumps and 4 unpressurized shell-and-tube heat exchangers. The magic is in the recipe.

About the labeled items in the above sketch:

Label (In Alphabetical Order.) Explanation

Reactor Tank

4 Circulating Pumps

Primary to Secondary Salt Loops Heat Exchanger

Over half of the 1,200 supersized power plants are on navigable water, making shipyard mass produced concrete "Reactor Barges" a cost-attractive approach. They would be parked in filled-in slips cut next to a power plant’s turbine gallery. If desired, a great deal of physical security can be economically added. Such "Reactor Barges" would act as catch basins in the event of an accidental spill, "float" on the ground during an earthquake, be "high and dry" in the more likely event of a storm surge, be easily returned to a factory for its 30-year refurbishing-refueling, and be easily removed forever when no longer needed, leaving no residual radiation or nuclear power site decommissioning costs.

________________________________________________________________________________________

Panamax Ocean-Going Barge

A Panamax cargo ship would typically have a DWT of 60,000 to 80,000 tonnes and a maximum cargo intake of 52,500 tonnes.

Smaller Seagoing Barge: 150' x 40' x 10' 965 Short Tons.

Larger Seagoing Barge:

210' x 60' x 13' 6" 3,050 Short Tons.

U.S. River Barge: A typical large river barge measures 195 by 35 feet (59.4 m × 10.6 m), and can carry up to 1,500 short tons of cargo. 9 feet of draft is typical.

The Model "T" reactor is about 29.9 feet in diameter, 30.8 feet tank height. That makes it a candidate for the 60' wide, 201' long, 13.5' draft, 3,050 short ton, larger seagoing barge.

http://www.atomicinsights.com/aug96/Conventional.html

________________________________________________________________________________________

Squeezing the cost of a nuclear boiler down to its practical market value.

Mass production is important to cash-strapped Global Warming mitigation. Never underestimate the power mass production has over price. The Model T sold for $850 in 1909, by 1920, mass production brought the price of a higher quality Model T down to $290, or 1/3 the 1909 price. Mass production is the way to dramatically bring unit costs down and quality up. To date, there have been no mass produced basic nuclear boilers. The author has found several references to such in the literature and has added David Walter's version to this page.

Getting an idea of a Model "T" reactor's price.

Mass Production

Construction of a Nuclear Reactor

To end 3/4 of coal's Global Warming we will need to

manufacture, transport, install,

and fuel about 5,000 Model "T" reactors or equals.

The reactors needed to replace Mega-Boilers will have to be built by shipyards

on barge/foundations for transport.

Rod Adam's article about Westinghouse's reactor-on-a-barge concept

Building the

"Reactor Barge" in a shipyard.

David Walters from Left Atomics, "A LEFT-WING PRO-NUCLEAR ENERGY PERSPECTIVE, FIGHTING FOR A SAFE, CLEAN AND SUSTAINABLE ENERGY FUTURE WHERE GENERATION IS FOR HUMAN NEEDS AND NOT FOR PROFIT" http://left-atomics.blogspot.com/ David has an idea that's too good to ignore for any future reactor - large or small. David has been working hard with others on what the author hopes will be the successor to the Model "T" reactor - the Liquid Fluoride Thorium Reactor or "LFTR' (called "Lifter") reactor. The LFTR is a reactor that really has the "Punch" needed to replace coal-burning boilers. It has all the power you could possibly want and will deliver it in steam or supercritical water at whatever temperature any turbine designed for coal steam needs.

LFTRs can run well on the very plentiful energy metal, thorium, once the thorium has been made radioactive by spending time in a running power plant reactor's neutron flux. LFTRs haven't been developed by any of the nuclear countries in the past because uranium is plentiful and cheap and LFTRs have no weapons potential.

TAICHUNG offers Taiwan (and China) a once-in-a-lifetime opportunity: Taiwan has shipyards. Taiwan could license the Model "T" reactor from the U.S., build them first for the TAICHUNG project to build Taiwanese expertise in "Universal Remediation Reactors", then build and float them to the rest of the world, becoming the world's dominant country in the manufacture and export of 1,000 MWe (1.4 million horsepower) nuclear reactors thermally optimized for replacing the world's large coal-burning power plant boilers. Once they get a few years and a few projects under their belts, their experience and developed manufacturing base would make it highly unlikely any other country could catch up with China. Rosatom could continue to be the fuel vendor.

Since we are talking only about the reactor, not the whole power plant, things are not as large as they may first seem. Using a barge as a foundation could also add a great deal of earthquake resistance to the reactor.

See also:

http://www.atomicinsights.com/aug96/Offshore.html

From David Walter's web site: Various approaches to the building of the Liquid Fluoride Thorium Reactors (LFTR).

"The small

scale size of the LFTR…maybe as little as 1/3 the size of an equivalent Light

Water Reactor for the same MW output...and the ability to build LFTRs from as

small as 5MWs up to 1.8 GWs (or bigger) gives LFTR siting a far more flexible

deployable possibilities than any other source of energy except, perhaps, diesel

electric generators used throughout the world for smaller grids and remote

applications.

But the smaller intermediate units, from the 100 to 500 MWs range, used as a

replacement for gas fired peaking units (site restricted for environmental

reasons and access to natural gas lines) and baseload replacement of coal, allow

a more creative approach to application of this, real Generation IV fission

energy.

My own contribution to this in the past few years was the "Missile Silo"

paradigm. A subsurface structure, with a removable, concrete reinforced 'lid' on

top, making for barely any above ground profile.

Excavations can be made using standard industrial

reinforced concrete for the floor and sides, much of that modularly cast above

ground and installed below ground. The LFTR modules, turbine generator train,

etc can be brought in and lowered into place and assembled. Only the control

room and, the air/water coolers would be above ground (air cooled condensers or

low profile cooling towers/once through cooling if located near surface water

supplies).

LFTRs are small because they are operate at normal atmospheric pressure and

don't require the huge containment domes and heavy piping you see around nuclear

plants today.

But there is

another, more fascinating, and perhaps much cheaper way to deal with LFTR sites.

Build them on barges in shipyards and ship them whole to any site with navigable

sites…like existing coal plants, for example, many that have river or canal

access.

The Russians are in the process now of building floating nuclear power plants of

the pressurized water reactor style used on Russian maritime vessels and

submarines. They are marketing them as being deliverable almost anywhere in the

world. The LFTR can follow this paradigm but the floating LFTR is not what I'm

proposing.

Secondly, Northrop Grumman Shipbuilding and nuclear giant Areva just started

construction of their

nuclear components factory at Grumman's Newport News

Shipyard: to use the facilities, cranes and dry-dock to help build, assemble and

ship their components around the globe.

The barge the LFTR would be sitting on would not be a temporary structure

designed to either transport the LFTR or as a permanent floating lodge for the

power plant.

Here is a generalized outline of how the construction/assembly/shipping/siting

would work:

1. Factories and machine shops in the shipyard would upgraded, where needed,

to nuclear specifications.

2. These factories and shop would forge, shape, assemble and finish components

for the LFTR.

3. Additionally components manufactured elsewhere would be laid out in the

shipyard.

4. A barge would be built big enough to transport, either for ocean going or

inner-coastal transport, that would be towed to the siting.

5. The LFTR barge would be assembled in the dry dock using existing facilities

at the shop yard. Cast concrete comes to mind.

6. As the barge is built from the bottom of the dry-dock up, the main decking

would be jacked up over the keel of the barge and sub-assembly of the LFTR and

it's main components would be assembled: reactor core, associated piping, heat

exchangers, [no turbine, generator, or lube oil for a boiler-only replacement

project - JPH] and associated balance of plant equipment.

7. The barge would be built for permanent dry stationing at a prepared site.

8. The site would be excavated and prepared with a temporary caisson off the

main navigable waterway. The caisson is like a dam used to block water from

flowing into the dry dock.

9. After the LFTR barge is assembled and towed to the site the caisson would

be put back in place and the barge/site temporary dry-dock would be drained.

10. The LFTR barge would settle on prepared pre-stressed concrete blocks.

11. The LFTR barge itself would be of steel and concreted design and completely

self contained as a nuclear power plant.

12. 1 large LFTR could be transported and sited this way or numerous smaller 100

to 500MW LFTRs on one barge as needed-->All "Factory Assembled".

13. The areas around the barge and supports could then be filled in with spoil

or clay or concrete depending on regulations.

14. Hooking up the LFTR to the site balance of plant would commence (station

power, grid access, control room, etc).

Charles Barton and others at

energyfromthorium.com/forum

are noted for advocating that the smaller LFTRs

be constructed in-lieu of a larger one because it could be completed basically

in a small series of modules and easily trucked and then assembled on site. This

would be next to impossible for the

larger 1GW-plus reactors as even the smaller-per-MW LFTR of this size is way to

big. The advantage of course of the smaller ones is that they could, in theory,

be composed of all-assembly line built components mass produced for low price

and high volume.

The shipyard metaphor, described above, combines both this concept of factory

production with the "line production" of large air craft and ships using

existing facilities that give LFTR manufacturers the

flexibility of designing any number of

sized LFTRs, from the smallest 5 MW (or smaller) which could be shipped on an

air plane to multi-module larger sizes of the plus-GW capacity…all factory

produced and assembled, ship whole and

sited in one fell swoop."

JPH Thought: Water tables at power plants are often high due to the proximity of cooling water. This can complicate sealing a below grade silo. Weather can also be a factor at many of the world's seaside power plants. As an example, the huge Big Bend coal-burning power plant, located on Tampa Bay near Tampa, Florida, is in a hurricane storm surge prone area. Dredging an access channel through the coal storage yard to near the power plant, riving foundation pilings, running the barge in, attaching the barge to the pilings at high tide, then building a super-thick nuclear containment silo around the reactor higher than any possible storm surge - perhaps 40 feet above sea level, finally, mounding dirt or fly ash capped with paving around the silo might also be given consideration.

The bulk dirt handling equipment to bring in and shape the dirt is already on site - the coal handling railroads, barges, bulldozers - should be able to make a 50 foot high by 100 foot in diameter, or a thousand feet long in the case of, say, four reactors in a row, containment mound with an access road along its top in a relatively short time for not too much money.

Unlike conventional water-cooled

reactors, the possibility of a catastrophic steam explosion with IFRs or LFTRs

doesn't

________________________________________________________________________________________

Links Fixed Down to Here Nov 20 2011

are also capable of mass producing Reactor Barges

http://en.wikipedia.org/wiki/Shipyard

United States: Electric Boat

(EB) Private

Russia: Russian Shipyard No. 10—Shkval -- is located in

Polyarny

Northrop Grumman Newport News shipyard

Notice nuclear aircraft carrier in center of picture.

Gdynia shipyard

Mass producing the Reactor Barges

Any country that can make a superheated steam boiler that will last several years before burning out can make acceptable reactors.

Production lines provide substantial quality and cost benefits. That's good because over 7,000 will be needed.

________________________________________________________________________________________

UK partnership for major components

01 September 2010 http://www.clbh.co.uk/

A British shipbuilder aims to 'catapult' itself into the nuclear industry with a partnership to bid for module construction jobs.

Cammell Laird boasts a large manufacturing base on the Mersey River near Liverpool where it primarily builds, repairs and refits ships. It can also undertake specialist electrical, thermal insulation and sheet metal work as well as heavy engineering. The firm is already involved in the UK's push for offshore wind power capacity and recently signed to partner with Nuvia for nuclear construction work.

"This is just the beginning of what we hope will be a relationship of towering achievement," said Cammell Laird chief executive John Syvret. "The nuclear sector, like the off shore renewables sector, presents huge growth potential for Cammell Laird."

The companies said they would "join forces to bid for contracts for the fabrication of heavy modules and components for new nuclear plants." While Cammell Laird will bring manufacturing capability, Nuvia will provide the nuclear expertise. That company traces its history back to the beginnings of the UK nuclear program but is now part of Soletanche Freyssinet, itself part of the Vinci construction group.

(Right) The construction hall that could begin making nuclear power plant modules. (Image: Cammell Laird)

Key to the operation would be Cammell Laird's construction hall which covers some 40,000 square metres and can handle modules of up to 1000 tonnes. The company said "due to its ability to slipway launch as well as conventionally load-out or transport via road, the size of module that can be produced is usually only governed by the transport medium."

The pair said they were

interested in modular construction work in the UK market and that preparation

for bids was already underway.

Researched and

written

(Right) Example of a highly government-regulated, physically large, multi-million dollar product being made at the rate of one a day.

Some of the wind is at our backs. Since these reactors are limited-life and built as a stop-gap solution to an emergency, we can sacrifice a lot of thermal efficiency for safety, simplicity, and reliability.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

about building Reactor Barges in modules.

The competition arising from simultaneous mass production of standardized reactors in as many as 8 different countries will bring about an amazing drop in both the reactor's fabrication complexity and cost while creating "build quality" competition.

http://en.wikipedia.org/wiki/Cargo_ship

________________________________________________________________________________________

The Coal2Nuclear

concept:

"A terrific application for several [nuclear] heaters that can produce 400

MW thermal at about 800 C is to replace similar sized boilers at coal fired

power plants. Like Jim Holm, I think that

Coal2Nuclear is the best way to make use of the investment at existing coal

fired facilities for items like steam plants, electrical distribution, and

cooling water. I think the conversion would be a heck of a lot cheaper than

trying to install the chemical facilities and plumbing required to capture and

sequester CO2. Preventing pollution is often cheaper than trying to cure it." --

Rod Adams,

http://www.atomicinsights.blogspot.com/

Heat Transfer Salt source:

http://www.dynalene.com/HeatTransferFluids/MoltenSalt.html?gclid=CLeeicHW66kCFUHu7QodJWVLZg

Building your own "Model T"? It seems to the author a person could build at least several of these molten salt reactors and their concrete containment cells for the same cost - say, 400 million - as a single typical Loeffler boiler in a coal-burning power plant.

In fact, the special pumps needed to

circulate the molten salt are available on the web at:

http://www.flowserve.com/Products/Pumps/Vertical/Wet-Pit/Molten-Salt-VTP-Pump%2Cen_US

Designed to move the large volumes

of very hot molten salt used in huge desert solar heat collection systems, these

pumps are not currently nuclear-rated (only the ones in the reactor cell that

move radioactive fuel salt need to be nuclear-rated).

FlowServe's VTP pump series have performance specifications far better than needed.

Flows to 13 600 m3/h (60 000 gpm)

Heads to 530 m (1740 ft)

Pressures to 100 bar (1450 psi)

Temperatures to 600°C (1100°F)

Settings to 20 m (65 ft)

Please show this web page to someone who builds large things for a living - preferably power plants. Solicit their opinion.

________________________________________________________________________________________

Russian Nuclear Barges

Russia, China work on advanced nuclear barges, reactors.

08 December 2011

Russia and China have held their first meeting for cooperation in the development of marine nuclear energy for floating power plants and potentially for propulsion of large ships.

While hundreds of nuclear reactors have been employed in the military navies of China, France, Russia, the UK and USA for decades, only Russia has maintained a fleet of civil nuclear ships: the icebreakers that work the country's Arctic ports and one freighter. Other countries' forays into civil marine nuclear power - the NS Savannah, the Otto Hahn and the Mutsu - did not continue in the long term due to various social, economic or technical factors.

Russia went on to expand its leadership in this area with the adaptation of the KLT-40S small reactor for installation in pairs on a barge. This vessel could be docked in remote places to supply power and heat either to the local population or new industry. The first such floating nuclear power plant, the Akademic Lomonosov, is at an advanced stage of construction at the Baltiysky Zavod shipyard. The barge is completed and afloat, with main power systems already fitted. Eventually it will be maneuvered along rivers and canals to the Arctic sea and towed to the town of Vilyuchinsk on the Pacific coast of Kamchatka Peninsula in Russia's far east. Another is planned for Pevek, on the Arctic coast.

Chinese interest in this kind of power source has grown steadily in recent years and has now reached the level of formal cooperation. The first meeting for this was held at the end of November in Chengdu, Sichuan province. Around the table were representatives of power plant operator Rosenergoatom, designer OKBM Afrikantov as well as China National Nuclear Corporation (CNNC) and its subsidiary the Nuclear Power Institute of China.

Rosenergoatom reported a 'high degree' of interest from the Chinese side, 'with a view to joint development of design solutions for the construction of floating nuclear power plants in China and joint promotion of projects in third countries.'

The bilateral cooperation group talked about the possible direction it could take. China is primarily interested in deploying floating nuclear power platforms for oil and gas installations at sea, and for the service of remote communities. Another application under consideration in Beijing is the propulsion of large cargo ships, for example on point-to-point routes carrying heavy cargo like mineral ore.

Based on the status of the Akademik Lomonosov, Rosenergoatom said it had at its disposal 'a full package of design documents to create a reference floating nuclear power plant for China'.

China has given a set of proposals to Russia for consideration as dialogue continues ahead of the next formal meeting in May 2012. Separately the countries are discussing cooperation for space nuclear power systems, and from mid-2012 Russia will supply radioisotope thermal generators to the Chinese space program.

In more conventional nuclear power, Russia has already built the two-unit Tianwan nuclear power plant in Jiangsu province, where two more are expected to be fully contracted soon. OKBM led the construction of the 65 MWt China Experimental Fast Reactor near Beijing, and a 1000 MWe power-generating version is slated to begin construction in 2017 known as the China Demonstration Fast Reactor. Before that, however, could come two BN-800 fast-reactor units also by OKBM at Sanming, on which construction could start in 2013.

Researched and

written

by World Nuclear News

Court seizes floating nuclear plant

15 August 2011

The world's first floating nuclear power plant, currently under construction, has been seized by the Court of Arbitration of Saint Petersburg as the shipyard building it faces bankruptcy proceedings.

The largest shareholder in the Baltiysky Zavod shipyard, with an 88.3% stake, is United Industrial Corporation, which is owned by Sergei Pugachev. This stake has been pledged to Russia's Central Bank as collateral for an unreturned loan to International Industrial Bank, another Pugachev-controlled company which was declared bankrupt in November 2010. The shipyard therefore appears on the brink of bankruptcy.

At the request of Rosenergoatom, the court has now impounded the partly-built vessel at the Baltiysky Zavod shipyard. Rosenergoatom was afraid that it could lose its investment in the 9.8 billion rouble ($340 million) project if another claimant seized the shipyard's assets during bankruptcy proceedings. The Arbitration Court - an independent permanent court under the St Petersburg Chamber of Commerce and Industry - ruled in Rosenergoatom’s favour on 26 July that the company stood a "significant risk" of losing its investment in the project.

Although the vessel - the Akademik Lomonosov - has already been registered in the name of Baltiysky Zavod as a ship under construction, Rosenergoatom is seeking to have it re-registered in its name as it claims it is the rightful owner. The vessel, it says, has been built using its funds. A certificate of ownership in Rosenergoatom's name would prevent the floating plant being seized as part of Baltiysky Zavod's assets.

In addition, Rosenergoatom claims that the shipyard's risk and civil liability insurance for the construction of the floating plant has expired and that Baltiysky Zavod has failed to fulfil its obligation to provide Rosenergoatom with a bank guarantee of return of advanced payments. The court also noted confirmation of the "financial hardship" of the shipyard.

The arbitration court sided with Rosenergoatom and ruled that taking possession of the Akademik Lomonosov on the company's behalf was justified.

The keel was originally laid for the first floating plant at the Sevmash shipyard in Severodvinsk in April 2007. However, in 2008, Rosatom said that it was to transfer its construction to Baltiysky Zavod because Sevmash was inundated with military contracts. A contract was signed in February 2009 between Rosatom and Baltiysky Zavod for completion of the plant. Construction of the plant has since progressed, with the turbo-generators recently being installed. The two 35 MW KLT-40S nuclear reactors - similar to those used in Russia's nuclear-powered ice breakers - have already been assembled and delivered to the shipyard ready for installation.

Despite the seizure, a Rosatom spokesman told the Moscow Times, "Work is continuing as normal, and I think it should be commissioned on schedule by 2012."

Researched and written

by World Nuclear News

Turbines installed on floating plant

10 August 2011

Construction of Russia's first floating nuclear power plant is progressing, with the two steam turbines now in place on the vessel. The Baltiysky Zavod shipbuilding company in Saint Petersburg said that the "complex and time-consuming" process of installing the turbo-generators - each weighing 230 tonnes - was completed on 3 August. The turbines were designed and supplied by the Kaluga Turbine Plant. Baltiysky Zavod said that it is now installing and connecting cables between the two main switchboards and the transformer compartment and is preparing to install cables between the main switchboards and the back-up diesel generators. Some four kilometres of power cable are scheduled to be installed by mid-August, the company said. The first plant - called the Akademik Lomonosov - will house two 35 MW KLT-40S nuclear reactors, similar to those used in Russia's nuclear-powered ice breakers. The reactors have already been assembled and delivered to the shipyard. The plant is expected to be commissioned in 2012, after which it will be put into use in Vilyuchinsk, in the Kamchatka region in Russia's far east

Reactors ready for floating plant

07 August 2009

Russia's Afrikantov OKBM has completed the assembly of the second KLT-40S reactor for the country's first floating nuclear power plant, currently under construction in St Petersburg. The first reactor has already been delivered.

The assembly and acceptance testing of the reactor was

conducted at the Nizhniy Novgorod AtomEnergoProekt (NN-AEP). OKBM Afrikantov

designed and provided technical support for the manufacture of the reactor,

while Izhorskiye Zavody produced the reactor vessel and NN-AEP manufactured

parts for the reactor and assembled it.

The assembly and acceptance testing of the reactor was

conducted at the Nizhniy Novgorod AtomEnergoProekt (NN-AEP). OKBM Afrikantov

designed and provided technical support for the manufacture of the reactor,

while Izhorskiye Zavody produced the reactor vessel and NN-AEP manufactured

parts for the reactor and assembled it.

An acceptance committee has confirmed that reactor is to the required standard. The committee comprised representatives from NN-AEP, Afrikantov OKBM, from Energoatom's Directorate for the Construction of Floating Nuclear Power Plants, the Russian Maritime Register of Shipping and the Federal Service for Ecological, Technological and Nuclear Supervision (Rostekhnadzor).

Assembly of the first reactor for the floating plant was completed earlier this year and the reactor vessel for the unit was shipped to the Baltiysky Zavod shipbuilding company in St Petersburg on 31 May for fitment to the completed keel of the first floating plant, the Akademik Lomonosov. The pressure vessel for the second reactor was shipped on 5 August The reactor internals are scheduled to be shipped to the company in mid-August.

The Akademik Lomonosov will house two 35 MW KLT-40S nuclear reactors, similar to those used in Russia's nuclear powered ice breakers, and its generators will be capable of supplying a city of 200,000 people, officials said. OKBM has designed and supplied the reactors, while Kaluga Turbine Plant will supply the turbo-generators. The power vessel was originally destined for the Archangelsk industrial shipyard, which is near to Severodvinsk in northwestern Russia, but will now be deployed at Vilyuchinsk, in the Kamchatka region in Russia's far east.

Baltiysky Zavod is to complete the floating plant in 2011. It should then be ready for transportation by the second quarter of 2012 and is set to be handed over to Energoatom by the end of 2012. Rosatom is planning to construct seven further floating nuclear power plants in addition to the one now under construction, with several remote areas under consideration for their deployment. Gazprom is expected to use a number of the floating units in order to exploit oil and gas fields near the Kola and Yamal Peninsulars.

Assembly of Russian floating plant starts

20 May 2009

A ceremony has been held to mark the start of the

assembly of the world's first floating nuclear power plant in St Petersburg,

Russia. Construction had earlier been transferred from Severodvinsk.

The keel was originally laid for the first floating plant -

the Akademik Lomonosov - at

the Sevmash shipyard in Severodvinsk in April 2007. However, in 2008, Rosatom

said that it was to transfer its construction to the Baltiysky Zavod

shipbuilding company in Saint Petersburg because Sevmash was inundated with

military contracts.

|

|

|

Five floating

reactors could go to Gazprom to power oil and

|

A contract was signed on 27 February 2009 between Rosatom and the Baltiysky

Zavod shipyard for completion of the plant. The contract was valued at almost 10

billion roubles ($315 million). A new keel has now been laid at Saint Petersburg

for the first floating plant. As part of the contract, Baltiysky Zavod will

receive the incomplete floating plants started by Sevmash.

The first plant will house two 35 MW KLT-40S nuclear reactors, similar to those

used in Russia's nuclear powered ice breakers, and two generators, and will be

capable of supplying a city of 200,000 people. OKBM will design and supply the

reactors, while Kaluga Turbine Plant will supply the turbo-generators.

The Akademik

Lomonosov was originally destined for the Archangelsk industrial

shipyard, which is near to Severodvinsk in northwestern Russia, but the vessel

is now destined for Vilyuchinsk, in the Kamchatka region in Russia's far east.

Baltiysky Zavod is to complete the floating plant in 2011. It should then be

ready for transportation by the second quarter of 2012 and is set to be handed

over to Energoatom by the end of 2012. Rosatom is planning to construct seven

further floating nuclear power plants in addition to the one now under

construction, with several remote areas under consideration for their

deployment. Gazprom is expected to use a number of the floating units in order

to exploit oil and gas fields near the Kola and Yamal Peninsulars.

Speaking at the ceremony, Sergey Obozov, director general of Energoatom, said

that construction of a second floating plant may start in the autumn of 2010. He

said, "We already have agreement with the authorities of Chukotka to station the

plant in Pevek."

Russia relocates construction of floating power plant

11 August 2008

The Russian government has approved a decision by

Rosatom to cancel the general contract with Sevmash for the construction of the

first floating nuclear power plant and to move production to Baltiysky Zavod.

|

|

|

How the floating plant could look (Image: Rosatom) |

According to Rosatom, the Sevmash shipyard in Severodvinsk

is inundated with orders and must concentrate its efforts on fulfilling federal

military contracts. The floating nuclear power plant project, together with

unused funds, will be returned to Rosenergoatom, the customer for the floating

plant.

Rosatom said that the government has approved the transfer of work from Sevmash

to Baltiysky Zavod, based in St Petersburg. Rosenergoatom and Baltiysky Zavod

have already agreed the preliminary terms of a contract, which Rosatom expects

to sign in the "near future."

The keel was laid for the world's first floating nuclear power plant - the

Akademik Lomonosov - at the

Sevmash shipyard on 15 April 2007. So far some 3 tonnes of steel, out of a total

9 tonnes, has been used in constructing the plant's hull and central section,

which will accommodate two small reactors.

The plant will house two 35 MW KLT-40S nuclear reactors,

similar to those used in Russia's nuclear powered ice breakers, and two

generators, and will be capable of supplying a city of 200,000 people.

Originally destined for the Archangelsk industrial shipyard in northwest Russia,

the Akademik Lomonosov will

cost an estimated six billion roubles ($232 million) to build. OKBM will design

and supply the reactors, while Kaluga Turbine Plant will supply the

turbo-generators. With the move of construction from Severodvinsk to St

Petersburg, the destination of the first floating plant is now uncertain.

However, Rosenergoatom said a decision would be made before October.

Rosatom is also planning to construct seven further

floating nuclear power plants in addition to the one now under construction.

Five of these will be used by Gazprom for offshore oil and gas field development

and for operations on the Kola and Yamal peninsulas. One is planned for 2012

commissioning at Pevek on the Chukotka peninsula, another for Kamchatka region,

both in the far east of the country. Further far east sites being considered are

Yakutia and Taimyr. In 2007 an agreement was signed with the Sakha Republic (Yakutia

region) to build a floating plant for its northern parts, using smaller ABV

reactors.

Russia also hopes to export the floating units to other countries for electricity and seawater desalination, operating for 15 years before returning to Russia for defuelling and maintenance. Countries including China, Indonesia, Malaysia, Algeria, Namibia, Cape Verde and Argentina are reported to have expressed interest in buying the plants.

Russian floating reactor construction starts

17 April 2007

The keel was laid for the world's first floating nuclear power plant at the Sevmash shipyard on 15 April. The Akademik Lomonosov will house two 35 MW KLT-40S nuclear reactors, similar to those used in Russia's nuclear powered ice breakers, and two generators, and will be capable of supplying a city of 200,000 people.

After decades of discussion, work has reached the first landmark stage in the development of floating nuclear power plants. Destined for the Archangelsk industrial shipyard in northwest Russia the Akademik Lomonosov will supply 70 MWe from two KLT-40S naval-developed reactors. It is estimated that the plant will cost around six billion roubles ($232 million) to build.

A ceremony was held at the Sevmash shipyard at which first Vice Premier Sergey Ivanov, the head of the Federal Atomic Energy Agency (Rosatom), Sergey Kiriyenko, and academic Yevgeny Velikhov fixed a memorable plaque on the body of the future plant.

Later, a memorandum was signed by Sevmash and Rosenergoatom (Russia's nuclear operator) for up to six more of the floating plants between 2008 and 2016. Two are envisaged for Pevek on Russia's Chukotka peninsula on the East Siberian Sea, while others are thought to be suitable for providing power to Gazprom's Arctic oil extraction operations. These uses would help Russia to achieve President Vladimir Putin's goal of having nuclear generate 25% the country's electricity by 2030.

The floating units could also be deployed in other countries for electricity and seawater desalination, operating for 15 years before returning to Russia for defuelling and maintenance. Other countries including China, Indonesia, Malaysia, Algeria, Namibia and Argentina are reported to have expressed in buying the plants, which could also be used for desalination.

Responding to safety concerns from the advent of a new type

of nuclear installation, Kiriyenko cited the 2000 Kursk disaster as evidence of

Russian naval nuclear excellence: "After the boat was raised, specialists proved

that the reactor could be put into service that very moment."

"If today we are building low-capacity floating nuclear power plants based on 70

MWe ice-breaker reactors, tomorrow, we will start building medium-capacity

plants based on unique technologies designed for nuclear submarines, ie 300-400

MWe" Kiriyenko said.

Some commentators, however, have expressed misgivings about

the safety of the floating plants, particularly their potential vulnerability to

accidents and terrorism.

Further information

WNA's

Nuclear Power in Russia

information paper

WNA's

Nuclear powered ships

information paper

WNN: Two floating nuclear plants for Chukotka