CHEAP GASOLINE ! ![]() Map

Restoring Our Oil

Independence

Map

Restoring Our Oil

Independence

Halting Global Warming

This is why people who are concerned about Global

Warming have failed miserably; they think this fact of life does not apply to

them.

They cannot fix their own cars and despise those who can. Why do they

think they can fix the machines that are making Global Warming?

They are their own worst enemies.

Contents

of this page

1) Planet Earth's Carbon Deposits

2)

Global Warming's Sources and

Sinks

3) Where Does Most

Global Warming Come From?

4)

What Can We Do About

Fossil Fuel Boilers?

5)

6)

7)

8)

9) Coal

10) Natural Gas

11) Oil

________________________________________________________________________________________

Why more, not less, energy is needed to halt Global Warming.

Simply put, more energy needs to be put into our fuels to refine out their Global Warming emissions properties.

________________________________________________________________________________________

Everything organic on Planet Earth is inextricably part modern and part fossil carbon.

This is why people who are concerned about

Global Warming have failed miserably. Not knowing how to fix the

fossil fuel industries that make Global Warming, they are telling them to

commit suicide. You can't tell an industry to commit suicide.

Re-channeling vehicle fossil fuels so they are "Green" was worked out in

detail about 5 years ago by NETL, the US Energy Department's National Energy

Technology Laboratories. One thing that stopped them was they did not have the

necessary heat source to power the processes needed to make fossil fuels

green.

I think the molten salt reactor has both the

temperature and the bulk energy to do the job.

Moving from less profitable markets such as heat in preference to more

profitable markets such as vehicle fuels is something any fossil

fuel company will gladly do.

That is what the author is suggesting.

Defining

"Halting Global Warming"

James Hansen pointed out that ending one pound of CO2 emissions does not stop one pound of CO2 from being added to the atmosphere.

How much benefit will reducing CO2 emissions produce?

(Right) About 46% of man's CO2 emissions ends up in the air. This implies that only 46% of any REDUCTION in CO2 emissions will be reflected in measurements of the air.

The important thing to remember

is that we have pushed up Planet Earth's thermostat. For the last 12,000 or so

years, we have been running at about 235 watts per square yard. The additional

heat we are getting is just two more watts per square yard and it will take

hundreds of years for Planet Earth to reach the new set-point.

Meantime, any additional burning of fossil fuels we do from now on just pushes the thermostat still higher. As you can see in the CO2 decay diagram, (left), dropping our CO2 emissions to about 2/3 of today's level will only cause the CO2 concentration to stabilize.

The world's largest producer of Global

Warming carbon dioxide is "Taichung," a coal-burning power plant

located on Taiwan. Just 1,200 of world's 30,000 fossil fuel power plants

make over 30% of ALL Global Warming. These coal burning "Mega-Plants"

(bright red in diagrams at left and right, click to enlarge) were built after the environmentalists

persuaded the world that equal sized nuclear mega-power plants were not

acceptable.

The world's largest producer of Global

Warming carbon dioxide is "Taichung," a coal-burning power plant

located on Taiwan. Just 1,200 of world's 30,000 fossil fuel power plants

make over 30% of ALL Global Warming. These coal burning "Mega-Plants"

(bright red in diagrams at left and right, click to enlarge) were built after the environmentalists

persuaded the world that equal sized nuclear mega-power plants were not

acceptable.

Examine James Hansen's graph

(above). Notice

how the rate of Global Warming, which had largely flat-lined during the

late-80s as nuclear mega-power plants were coming on-line, took a sharp turn for

the worse as coal-burning mega-plants began coming on-line.

Mega-Sized Power Plant List

.pdf

Examine James Hansen's graph

(above). Notice

how the rate of Global Warming, which had largely flat-lined during the

late-80s as nuclear mega-power plants were coming on-line, took a sharp turn for

the worse as coal-burning mega-plants began coming on-line.

Mega-Sized Power Plant List

.pdf

The coal-burning boilers in these 1,200 mega-power plants can be quickly replaced with small, ultra-safe, molten salt nuclear boilers. That would immediately end about 30% of ALL Global Warming. Converting the boilers on the world's remaining 29,000 fossil power plants would end about another 6%.

This engineer would suggest the first thing that should be done to halt Global Warming is to undo what the environmentalists have done.

"Bottom Up" halting.

The environmentalists appear to be suggesting: "Change your incandescent light bulbs to high efficiency fluorescent and hope something good happens."

________________________________________________________________________________________

2) Global Warming's Sources and Sinks

The diagram below shows the world's carbon flows into and out of the atmosphere as carbon dioxide in metric billions of tons. As you can see, vegetation on land and the ocean's water naturally remove some of the carbon dioxide from the air. As you can also see, man's ability to add carbon dioxide to the air is overwhelming nature's ability to remove it, leaving an accumulating excess in the air of about 12 billion tons per year (Red Bar). It is estimated that since man first began to overwhelm nature's ability to remove all of man's CO2 from the air about 1 trillion tons of extra CO2 have accumulated in the air.

The stacked bar chart on the right shows man's major CO2

sources (the fossil fuels) and how nature is dealing with it (CO2

sinks). The author got the coal, natural gas, and oil

Bottom Line: An additional 12 billion tons of carbon dioxide is accumulating in air every year

________________________________________________________________________________________

Boiler-driven machines make 2/3 of ALL Global Warming

The "CO2 Sources and Sinks" diagram from the "Global Warming Today" page is repeated here with another diagram that shows the "Sources" matched up with the "Fossil Fuel Emitter" machines that make and emit the CO2.

Most of coal, natural gas, and a little oil is used to heat boilers.

Most of oil is used to power vehicles with a little being used as feedstock for plastics and fertilizers.

Deforestation is associated with wood harvesting and "slash and burn" agriculture.

The important thing to notice is that much of fossil fuel boiler heating is for making electricity..

Fossil fuel boilers can be replaced by nuclear fuel boilers of about the same physical size. And, since nuclear heat is 1/3 to 1/20th as expensive as fossil heat, nuclear heat as a general source of heat may prove to be far less expensive in the long run.

Where are we burning most of our fossil fuels? We are burning 2/3 of our fossil fuels in boilers.

What fossil fuels

are we burning in our boilers?

Almost all Coal and

Natural Gas.

Source:

http://tonto.eia.doe.gov/energyexplained/index.cfm?page=environment_where_ghg_come_from

In the diagram below you can see how much heat is being used various sectors of the United States' population and, on the right, the carbon dioxide emissions that result from that use.

What this shows is that a

Transportation = 1,851

Electricity Generation = 2,147 (Does not

include hydro and renewables)

Industrial, commercial boilers, hot water heaters, furnaces combined =

1,407

All Boilers = 2,147 + 1,407 = 3,554

________________________________________________________________________________________

4) What can we do about fossil fuel boilers?

Coal and natural gas boilers can be repowered with nuclear boilers.

Fossil

Fuel Boiler Awareness

Most coal and natural gas is burned in

boilers so most Global Warming could be considered to be happening in boilers.

Hidden away, largely forgotten, all over the world,

perhaps a billion

huge-to-tiny boilers, hot water heaters and furnaces

are silently making most of the Global Warming CO2

that's overwhelming Nature. All day, every day.

hot water heaters and furnaces

are silently making most of the Global Warming CO2

that's overwhelming Nature. All day, every day.

Click on pictures for larger

images.

230 feet high, open-air for cooling, a pair of Babcock & Wilcox supersized coal burning power plant boilers. - Photo: B&W Brochure

50,000

Natural Gas

Burning Electricity Turbines make

about 4% of Global Warming's CO2

1 Million

Large

Industrial and Commercial Natural Gas Boilers

make about 4% of Global Warming's CO2

1 Billion

Small

Commercial Gas Boilers,

residential hot water heaters, and furnaces make about 4% of Global

Warming's CO2

Ocean-going ships, which could be nuclear powered, make about 4% of Global

Warming CO2.

Concrete production, which could be nuclear fired, about 3%.

EPA: The United States has 200,000 industrial boilers, heaters and incinerators. (US has about 20% of the world's boiler and heater infrastructure.)

Notes:

1. Boiler population numbers are 2005 world-wide counts or estimates.

2.

The advanced nuclear boiler that can replace supersized coal boilers - the

ORNL-TM-1060.

(Right) Classic American natural gas burning 800 horsepower industrial

boiler. Click on image to see a cutaway of this boiler - which is the same

concept as a classic steam locomotive fire-tube boiler.

- - Hurst Boiler & Welding

Hurst boiler brochure .pdf

(Above) a typical building complex boiler house. Click on images for larger view.

The Boiler "Donut Hole"

Currently there are no nuclear boilers smaller than 75 megaWatt (thermal) on the horizon. Dr. Peterson test ran a 15 megaWatt (thermal) uranium hydride reactor for his patent, but nothing about that reactor has been published in the last couple of years. Due to wire and transformer limitations and losses, there is an upper limit on how powerful an electric boiler can be.

This represents what is currently commercially practical in electric boilers.

From the

http://www.cleaver-brooks.com/Home.aspx

http://www.deanboiler.com/home.htm

What are these industrial boilers like? Here is a view of a typical 800 bhp (boiler horsepower) natural gas fired industrial boiler (inside view) Brochure .pdf From the Hurst Boiler Company brochure, their Series 200 natural gas 800 bhp (boiler horsepower) boiler burns 33,600 standard cubic feet of gas (a scf of natural gas has 1,005 BTU) every hour making 33.7 million BTU every hour.

Hurst's Web Site: http://www.hurstboiler.com/biomass_boiler_systems "Hurst Boiler & Welding Company, Inc. has been manufacturing, designing, engineering and servicing gas, oil, coal, solid waste, biomass & hybrid fuel-fired steam & hot water boilers since 1967. The Hurst Product Line includes Packaged boilers: 6 to 2000 hp, pressures to 450 psi. Fire-tube, water-tube & feedwater equipment for all heating & process applications including: schools, dry cleaning, hospitals, universities, military & all commercial/industrial operations. Hurst is a custom manufacturer of engineered packaged boilers & boiler systems, biomass boiler systems, boiler controls & accessories. Low NOx modular boilers & burner configurations are available for all models, starting at 9.5 hp, meeting all state environmental requirements, including SCAQMD." - - from "About Hurst Boiler & Welding Company" on the Hurst web site.

Going Green. To make 33,700,000 BTUs of heat in an hour using electricity from any source, you would need about 11 million electrical watts for an hour (it takes a watt an hour to make 3.41 BTUs).

What will the "Small Energy" picture be like when all we

have is nuclear? Small stores would be well served by electrical heat

and cooling; "Big Box" stores, like WalMart and

There is a huge gap between the 25 MWe (about 70 megaWatt thermal) obtainable from the smallest commercial reactor that's about to come on the market - the Hyperion - and what thermal energy may be obtained from the typical 4kV 3 phase city electrical distribution line.

The classic American 800 boiler horsepower boiler consumes about 33,600

Standard Cubic Feet

A Cleaver-Brooks CEJS 4200 25 kV electric boiler, rated at 56 megaWatts (173 million BTU), is 1616 amps with a power factor of 0.8. This is as much power as some small rural coal power plants make.

To do 70 MW thermal at 4,160 volts 3Φ, would take 12,144

amps at 0.8 pf. Loads over 400 amps on a typical city distribution

line is an impractical amount of current. 400 amps is about as high

as we can go. So a This should cover small individual stores.

This should cover small individual stores.

A typical large load would be a hospital campus, school campus, office complex, shopping mall, etc. What would make operational and economic sense is to get one or more Hyperion nuclear heat modules (right), use the heat for heating, cooling, and generating electricity. Today's windmill and solar cell electricity feed-in rules should make it easy to sell any occasional dispatchable electricity into the local distribution grid.

A great little electrical power calculator: http://www.jobsite-generators.com/power_calculators.html

Basic electricity distribution components. Below, from: http://en.wikipedia.org/wiki/Electricity_distribution Notice all circuits are 3 phase (Φ), 60 Hz.

(Above) Higher-voltage transmission lines are more typical of a grid several hundred miles in diameter. kV = kiloVolts or thousands of Volts.

________________________________________________________________________________________

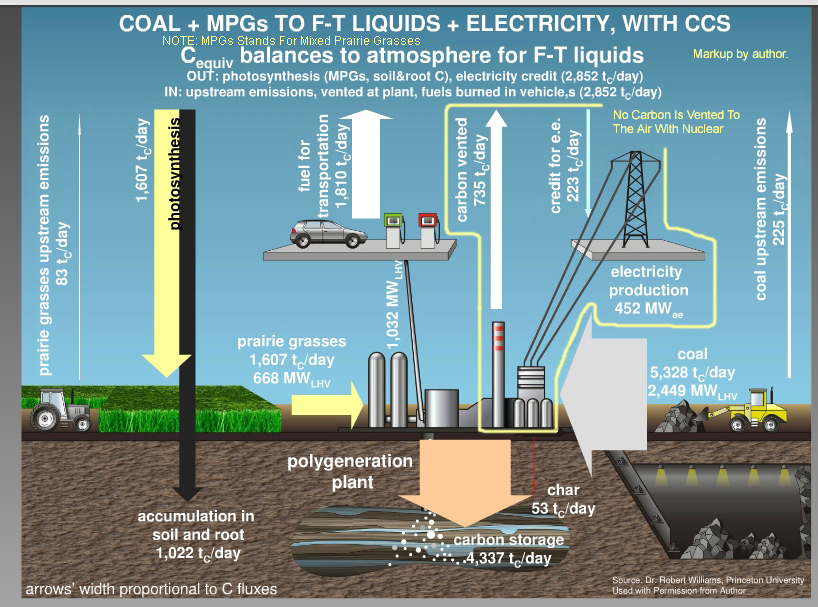

5) A Zero-Emissions Coal + Biomass Synthetic Oil Refinery

A Zero-Emissions Synthetic Oil Refinery

for Making Net-Zero Emissions Transportation Fuels

This is the difficult part. By using high temperature nuclear heat instead of coal heat to make coal-to-oil, you are painting with a different palette.

The RAND Corporation studies indicate that complete capture and disposal of CO2 emissions would add less than $5 to a barrel of CTL oil, burning coal to make oil.

Co-generation of electricity by burning unusable process gas is the major source of CTL's Global Warming emissions. Since this is no longer acceptable, this gas must be kept inside the product stream or become part of the CCS disposal stream.

If coal-to-oil is to be done

squeaky-clean, we will have to use high temperature nuclear heat and capture the

inevitable streams of CO2

and H2S.

This will take more processing, more expensive heating equipment such as

Westinghouse-plasma electric

torches with 1,000 hour electrode life to vaporize the coal feedstock. ![]() But it can be done. The author has a 2002 Westinghouse Plasma Corporation

paper about a "next-generation" Plasma Gasification Reactor study with a

capacity of 360 tons/day. 42 of these gassifiers would vaporize the 15,000 tons

of coal per day. At 1/2 billion dollars.

But it can be done. The author has a 2002 Westinghouse Plasma Corporation

paper about a "next-generation" Plasma Gasification Reactor study with a

capacity of 360 tons/day. 42 of these gassifiers would vaporize the 15,000 tons

of coal per day. At 1/2 billion dollars.

The biggest hit will be the additional energy needed to make clean happen. But, heat from thorium is so cheap it is almost free. That's the trade-off.

And nuclear promises even cleaner, more energetic synthetic fuels (higher miles-per-gallon) than today's fuels if we can manage to cleanly obtain the hydrogen available from water to upgrade the oil molecule even more. "A nuclear source of hydrogen coupled with nuclear process heat would more than double the amount of liquid hydrocarbons from the coal and eliminate most CO

2 emissions from the process." - http://world-nuclear.org/info/inf116_processheat.htmlThe coal-to-oil conversion

process produces ultra-clean clean fuels with all of coal's solid pollutants

being trapped in the coal's solid waste char and gas pollutants captured during

refining. Coal-to-oil conversion is a well-known process, and its environmental

aspects are well-documented by many sources. (Click to enlarge.)

![]()

Environmental impact. Converting our 286 largest power plants from coal to nuclear to make both electricity and synthetic oil would end about 40% of ALL U.S. Global Warming emissions. If the solid waste, CO2, and H2S (sulfur) from the coal refining process is sequestered, then there should be no objections about use of ultra-clean synfuels produced from coal.

Replacing all of America's imported oil would consume a little more than ALL the coal the U.S. is currently burning to make electricity.

To make this all environmentally sane, the EPA should make the allowable combined power plant and coal-to-oil refinery emissions equal to or lower than had the power plant alone converted to "Carbon Capture and Sequestration" emissions control instead, i.e., an 80% or more reduction in ALL emissions, including CO2 (carbon dioxide). CCS backgrounder: http://en.wikipedia.org/wiki/Carbon_capture_and_storage

More on the zero-emissions synthetic oil refinery page >

________________________________________________________________________________________

6) A Water-Splitting Hydrogen Generator to Upgrade Coal Molecules to Oil Molecules

A

Water-Splitting Hydrogen Generator to Upgrade BioCrude to BioGasoline

Upgrading and refining synthetic crude oil made from coal and biomass. Crude oil made from coal + biomass from all sorts of sources will be very pure but composed of a wide variety of different molecule weights that will have to be broken down (cracked) into vehicle-ready fuels. The 1,300°F heat from the reactor will hit the spot for catalytic cracking of some oil molecules; other synthetic oil molecules will need hydrocracking which, in a conventional oil refinery, uses hydrogen from natural gas, a process that produces large amounts of carbon dioxide.

Small amounts of hydrogen can be obtained without Global Warming emissions from electrolyzers. If large amounts of hydrogen are needed, the extremely high temperature water-splitting sulfur-iodine process will have to be used. The reactor's 1,300°F heat isn't quite hot enough to drive the water-splitting process, but when another 350°F is added via electrical heat booster elements, the FLiBe heat transfer salt should be hot enough to get the job done. Both electrolyzers and calrod heat boosters consume a lot of electricity. Being located at the power plant, they avoid costly electricity transmission costs.

http://en.wikipedia.org/wiki/Oil_refinery

http://en.wikipedia.org/wiki/Hydrocracking#Hydrocracking

http://en.wikipedia.org/wiki/Algae_fuel#Biogasoline

________________________________________________________________________________________

7)

Endless Heat Is

Necessary To Make Endless Oil

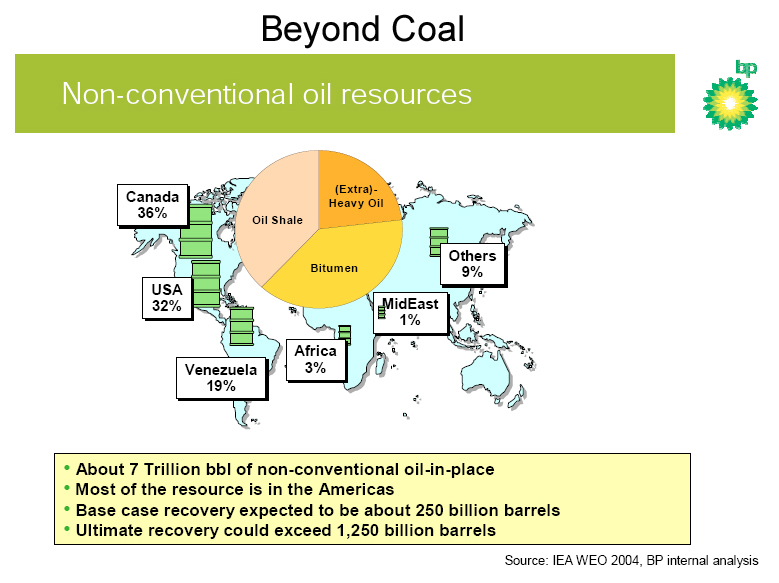

The US has virtually

endless

feedstock for making oil, but we also need endless, clean, very hot heat to

make endless clean oil. While we do have 27% of all the world's coal, we can't

burn coal or natural gas because they are our feedstocks, it is becoming obvious

coal is so valuable we simply can't afford to burn coal to make the necessary

heat for producing electricity or synthetic oil. Coal reserves expectancies

chart: ![]() Windmills are clean and endless but don't make heat. That leaves only nuclear

heat. (Click to enlarge image at right.)

Windmills are clean and endless but don't make heat. That leaves only nuclear

heat. (Click to enlarge image at right.)

![]()

THE BAD NEWS: The nuclear reactors we are using today are simply not hot enough at 550°F to do anything much beyond boiling water to make electricity.

THE GOOD NEWS: Another type of reactor, the air cooled 1,300°F high temperature Molten Salt Reactor is hot enough to replace the coal being burned in power plants and also to convert that coal into crude oil. This much safer reactor has little in common with today's reactor.

Reality Check: At the present time, there are no molten salt reactors in operation. The US government abandoned molten salt reactors about 1972 when it was understood that thorium had near-zero nuclear weapons value. That was then, this is now. You wouldn't be reading this if liquid thorium were not being "taken back off the shelf" in many places for many reasons.

For the purposes of showcasing a Molten Salt Reactor on this web site, the author has chosen the 1 gigaWatt (electrical) [2.5 gigaWatt (thermal) reactor and confinement cell combination designed by EBASCO.

Molten salt

reactors have little in common in physical size, cost, or the way they work

when compared to the solid uranium reactors in worldwide use today. The most

commonly suggested nuclear fuel for this type of reactor is

thorium. ![]() http://en.wikipedia.org/wiki/Molten_salt_reactor

http://en.wikipedia.org/wiki/Molten_salt_reactor

Top U.S. molten salt web site: http://energyfromthorium.com/

________________________________________________________________________________________

8) Making Fossil Fuels "Green"

SYNTHETIC BioGasoline from Blends of U.S. Coal + Biomass

"Carbon-Neutral" means

burning the biogasoline neither hurts nor helps Global Warming.

Coal + Biomass refining technologies for cheap, environmentally friendly transportation fuels

"Indirect" conversion of coal

into synthetic oil opens the door to environmentally friendly gasolines,

diesels, and jet fuels. By using Liquid Thorium nuclear energy to power the

"Coal and Biomass to Liquid" (CBTL) process, a substantial additional Global

Warming benefit can be achieved. Chart:

![]()

"Carbon-neutral" synthetic

gasoline, diesel, and jet fuel may be possible

when coal feedstock + certain biofuel feedstocks + carbon capture + nuclear heat

are combined. Results from some blends using coal heat + carbon capture

technology are very promising. Chart:![]() From:

http://en.wikipedia.org/wiki/Synthetic_fuel

From:

http://en.wikipedia.org/wiki/Synthetic_fuel

CTL - Affordable, Low-Carbon Diesel Fuel from Domestic Coal and Biomass - CBTL

Final Report .pdf

If the coal + biofuel blend folks are correct, it may be possible to come up with identical or better (and cheaper) gasoline, diesel, and jet fuels having net zero lifecycle CO2 emissions with surprisingly small percentages of biofuel in the blend if liquid thorium instead of coal burning is used to power the CTL conversion and if carbon capture technology is used to prevent the CO2 emissions normally associated with the CTL process from being vented to the air.

In addition to cellulosic biomass feedstock (grasses, woods), municipal solid wastes (MSW) and sewage are potential sources of carbon-neutral carbon. Plasma arc waste disposal, which gasifies municipal solid wastes using a device called a plasma converter, are a practical source of carbon-neutral feedstock producer gas. The useable syngas is drawn off the top off the gassifier, the slag and metals from the bottom. The non-metal solid wastes can be added to the wastes from the coal gassifier and placed in played-out mine shafts.

America's sewage alone can supply

almost 10% worth of gasifiable carbon-neutral feedstock for America's vehicles.

In these feedstock blends, coal is used as the sequestered (plant root) carbon

component (See "Comparing Fuels.")

http://www.corebiofuel.com/ Core Biofuel produces a 100% cellulosic biogasoline that is "greener" than carbon-neutral but burns to provide the energy to drive the process, thus reducing the "green-ness" of the final product.

http://www.sundropfuels.com/ Sundrop fuels are building a cellulosic biomass + natural gas synthesis plant that should be able to make exactly carbon-neutral biogasoline at a better than natural crude gasoline price.

What is being suggested by Restoring America's Oil Independence is far "Greener," than Core's or Sundrop's technology since the energy needed to make its biogasoline will come from extremely cheap CO2-free nuclear. It can blend coal + biomass for a variety of "green" or cheap biogasolines. (See "Comparing Fuels," right.)

________________________________________________________________________________________