Categories:

TIGHT OIL![]() Contents

Restoring

Our Oil Independence

Contents

Restoring

Our Oil Independence

Categories:

by adding synthetic oil

refineries to our largest coal power plants.

Oil Security

The “Restoring Our

Oil Independence” plan would increase the amount of oil energy available to

the world by about 12% with

NO net increase in Global Warming CO2 and a global

DECREASE of over 25% of coal’s biotoxic pollutants.

Endless, Non-Global Warming BioBlend Oil.

(Left) If you notice, the

imported oil slice of our energy pie and the coal slice are about the

same size. We could convert our coal into synthetic crude oil to end imported

oil and regain our energy independence.

How?

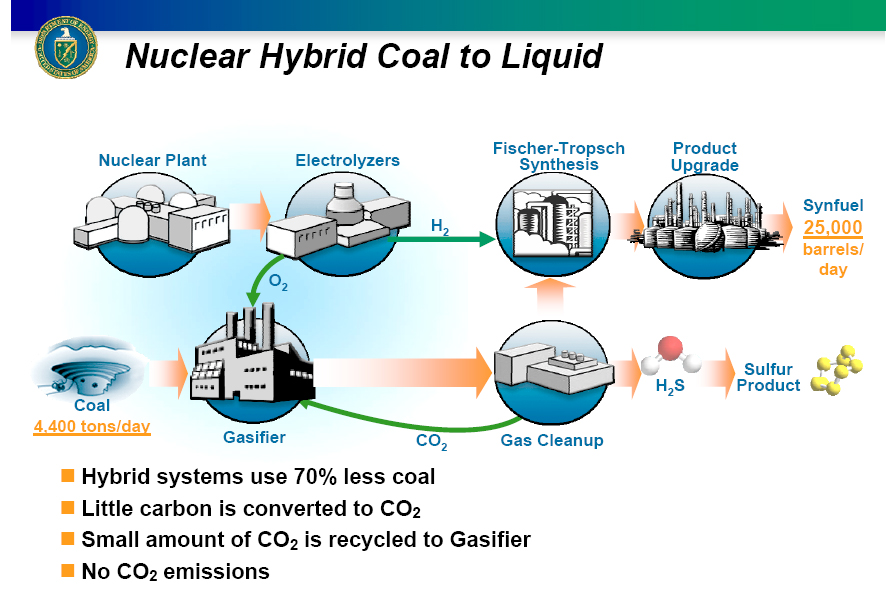

(Right) We would convert our 300 largest power plants to nuclear and then add

coal-to-oil refineries to the now-nuclear power plants to make the oil.

The power plant's unneeded coal transportation, coal handling, and coal

pulverizing equipment would be reconnected to the coal-to-oil refinery.

Solving America's oil supply problem

will solve the World's oil supply problem

Global Peak Oil has

arrived. "Peak Oil"

means the world simply can't pump oil any faster. For six

straight years,

![]() the world has been UNABLE to pump more than

about 74 million barrels of crude oil per day no matter how hard the oil

companies try. Planet Earth's oil spigot is now wide open. Can't

lift oil out of the ground faster.

the world has been UNABLE to pump more than

about 74 million barrels of crude oil per day no matter how hard the oil

companies try. Planet Earth's oil spigot is now wide open. Can't

lift oil out of the ground faster.

What recent global oil supply growth we have obtained has come from environmentally dirty unconventional sources of oil such as fracking "Tight Oil," melting down tar-like Oil Sands, and gasifying coal to synthesize it into oil.

Currently the world uses over 85 million barrels of petroleum per day and global primary energy demand is growing at a rate of 1.6% per year. That means that global primary energy demand will double over the next 40-50 years with global 100 mbpd, $240 per barrel, demand by 2035. Doubling an inelastic demand for an inelastic supply always means a drastic increase in price. Consider black markets. Oil situation in detail .pdf The U.S. imports a billion dollars of oil a day and burns 243 barrels of oil per second. How it looks for us.

Insecurity. If

petroleum is influence, what is our future?

Being dependent on imported oil

means America will ALWAYS be bogged down in one global oil insecurity crisis after another.

Insecurity. If

petroleum is influence, what is our future?

Being dependent on imported oil

means America will ALWAYS be bogged down in one global oil insecurity crisis after another.

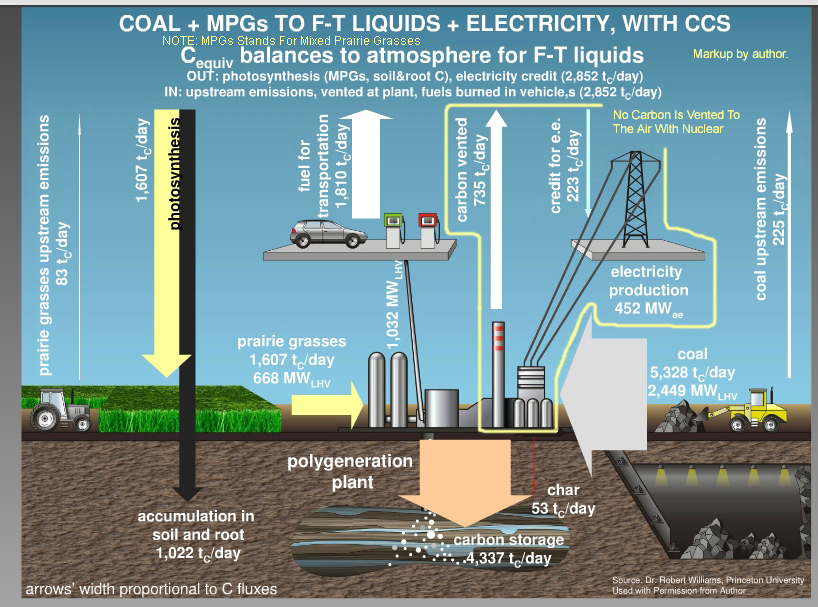

It doesn't have to be this way. It is America's good fortune to have both the natural resources and technology to escape Peak Oil's damaging effects. This same technology will also overcome Global Warming emissions in a way that will boost our economy with cheap conflict-free oil. BioCrude oil is an environmentally friendly synthetic crude oil that can be made from blends of biomass from plants plus coal or natural gas. If we so wish, we will never run low on biocrude oil.

The energy economics: Coal is selling at about $2 per million British Thermal Units (30.8 million BTU from a ton of coal at $68 per ton). This means the energy content in US coal is priced at the equivalent of about $13 per barrel of oil (5.8 million BTU from a barrel of oil), making coal energy about 1/8 of the cost of internationally traded crude oil energy, such as Brent crude ($104 on 10/1/2011). With a margin that large, using coal instead of oil to make vehicle fuel is highly attractive.

Reality Check:

Altona energy (UK)

believes it can supply vehicle-ready diesel at $53 a barrel ($1.26 per gallon)

from mine-mouth coal, by burning coal, at Arckaringa, Australia.

Synthetic bio-crude promises to be extremely profitable. Several U.S. "Green and Clean" synthetic fossil fuel + biomass bio-crude oil refineries are already in progress. Most advanced is Sundrop Fuel's state-of-the-art refinery, planned to be built near Alexandria, Louisiana.

Biofuel-only feedstock is a rougher row to hoe. Cellulosic biofuel feedstock, the biofeedstock that doesn't compete with food, is very difficult to break down. This is why the author is suggesting using a nuclear electricity powered Westinghouse plasma torch gasifier instead. Plasma gasifiers are powerful enough to gasify whatever is in your town's landfill. Coal - SRI Research Identifies Environmentally Friendly Process to Make Coal-Based Liquid Fuel .pdf The Zero Emission Coal Alliance. See also http://en.wikipedia.org/wiki/API_gravity

To Blended Biocrude Oil Refinery

Restoring America's Oil Independence

is suggesting that instead of burning our coal to make electricity, we repower

our 300 largest coal burning power plants with thorium nuclear to make electricity,

then add coal + biomass-to-oil refineries to these power plants. We could

reconnect the power plant's coal transportation, handling, and pulverizing

equipment to the refinery and

convert our coal

into synthetic bio-crude oil to replace imported natural crude

oil. This would create hundreds of thousands of good paying jobs for decades to come.

Coal -

Cleaner Cheaper Liquid Fuel from Coal .pdf

This is a global opportunity. Adding nuclear boilers and coal-to-oil refineries to America's 300 largest coal burning power plants will enable America to sell its coal into world energy markets at increasingly higher world oil prices while assuring a secure and stable domestic supply of cheap gasoline, diesel, and jet fuel for Americans. OPEC has been doing this for its populations for decades. What's So Bad About Exporting Gasoline? .pdf

New energy

technologies make this plan possible.

1) Carbon Capture and Sequestration. To make the manufacture of

synthetic bioblends of oil

completely emissions-free.

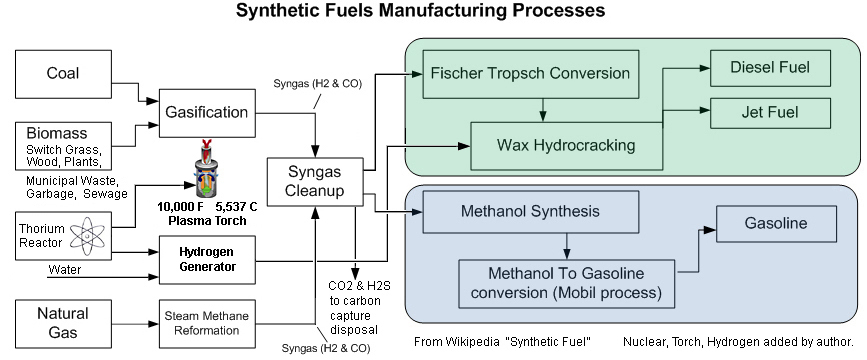

2) 10,000°F Plasma Torches. At 10,000°F, hot as the sun, to gasify

whatever is needed to make oil. Only by gasifying feedstock can you make

ultra-clean oil.

3) FLiBe heat transfer salt. Red-hot heat transfer salt has never been used

to transport massive amounts of heat

in power plants and coal-to-oil refineries before.

4) Naturally Fail-to-Cold Molten Salt nuclear reactors (MSRs).

Molten Salt Reactors have almost nothing in common with today's nuclear

reactors.

5) Thorium. The MSR will run well for 30 years on tiny amounts of either dirt-cheap

Thorium or plentiful Nuclear Waste from conventional reactors, producing 1% the

nuclear waste of conventional reactors.

6) Sulfur-Iodine water splitting process to produce the massive amounts of cheap

hydrogen needed to crack F-T waxes for making biodiesel and biojet fuel.

7) Hastelloy-N metal alloys for a nuclear reactor that contains corrosive red-hot

1,300°F molten salt.

8) Aircraft-Type Programmable Logic Controllers

to eliminate human operator error in the reactor, water-splitter, and the

refinery.

Coal +

Cellulosic Biofeedstock Logistics

Logistics

"You load 16 tons and what do you get?

The U.S. burns 36 tons of coal per second.

http://205.254.135.7/coal/

300+ U.S. communities have large power plants. They are already built and running. We will need their coal handling and processing equipment to feed our coal-to-oil refineries. Like coal, cellulosic biofeedstock would also come in on rail coal cars. Slag (there will be no ash) would be returned to played-out mines for disposal. CO2, H2S, and other gases would be captured and properly sequestered.

Every coal-burning power plant

has:

1) A large piece of real estate called a "Coal Yard."

It is usually large enough to hold several of the coal-to-oil refineries being

discussed here.

2) The necessary railroad (and often barge) connections, rotary dumper,

conveyors, coal crushers, and ash handlers to transport large volumes of coal

and coal ash. (Photo by author.)

![]()

3) Typically 16 coal pulverizers per power plant to turn coal into powder-like dust, essential for processing coal-to-oil.

4) The necessary federal, state, and local permits to consume and dispose of

large volumes of coal.

5) The necessary skilled trades workforce to competently operate and maintain

coal processing equipment.

6) The acceptance, good will, and support of the local community.

7) The perhaps 400 billion dollar total U.S. cost of mercury, SO2,

NOX, and CO2

emission systems retrofits or repowering with

liquid thorium nuclear.

Adding a Coal-to-Oil refinery will mean reconnecting and reusing the coal handling equipment. A 1 gigaWatt coal power plant typically has 4 generating units. The average power plant site in this size group consumes between 2.6 and 3.4 million tons of coal per year. LiquidCoal's suggested 50,000 barrels of diesel fuel a day coal-to-oil refinery would consume about 150 100-ton railroad cars of coal per day or about 5.5 million tons over a year. That's probably more than the typical large American power plant's coal equipment could handle on a sustained basis.

Perhaps a 3 million ton a year

coal-to-oil refinery would be more appropriate. A 3 million ton per year

CTL refinery might make about 6,500 tons (27,000 barrels of diesel and 19,000

barrels of other oils) of oil products per day. In addition to unloading

and handling the 8,000 tons of coal (82 cars) every day, 1,600 tons of solid

waste (16 cars) will have to be loaded, and the yet unknown amounts of captured gaseous

carbon dioxide and hydrogen sulfide (CO2

and H2S)

will also have to be transported away and sequestered.

The power plant will have to be converted to nuclear for several reasons: 1, coal is too costly; 2, avoid a boiler carbon capture rebuild; 3, free up what will become hard-pressed coal handling equipment. All generating units would have their coal burning boilers replaced with underground molten salt reactor heated steam generators located in a new, adjacent building. Once the coal pulverizers are removed, there should be ample room near the now-cold coal boiler to reconnect the turbine's existing steam lines to new steam feeds coming from the reactor's steam generator building. Bayside is an example of how long turbine steam lines can be (old brown turbine building on left, new gray heat recovery boilers on right).

Coal-to-Oil refineries will need to come in a variety of sizes, perhaps in 1,000 tons of coal increments, to fit the wide variety of power plant sizes found in America.

Powering the Plan

![]() Recycling our largest coal burning power plants into

thorium nuclear power plants.

Recycling our largest coal burning power plants into

thorium nuclear power plants.

![]()

Recycling

Power Plants

If we sell our coal as oil, we'll have to replace its heat from somewhere.

The only replacement source of massive amounts of cheap non-Global Warming heat is nuclear. America can't afford to build 300 new nuclear power plants. A practical option is to recycle our existing coal burning power plants into nuclear power plants by replacing their coal boilers with small underground nuclear boilers. Unfortunately, today's nuclear reactors make 550°F heat, about 1/2 as hot as the 1,000°F superheated steam most coal power plants must have. Another type of reactor, the molten salt reactor, can make heat hotter than 1,000°F.

While molten salt reactors can run on uranium-235, they can also run as "nuclear converters" on either the thorium "232" cycle or the nuclear waste "238" cycle, converting and consuming low-value energy metals unusable in conventional reactors. Heat from both thorium and nuclear waste can be thousands of times cheaper than heat from coal. This fact makes coal far too valuable to use as heat for electricity generation.

About molten salt

reactors. Many different types of nuclear reactors emerged from the

Manhattan project at the end of World War II. We developed a solid fuel

rod, water-![]() cooled reactor for powering submarines. Another type, completely

different from the submarine reactor, using fuel dissolved in a circulating liquid, was developed for powering airplanes.

cooled reactor for powering submarines. Another type, completely

different from the submarine reactor, using fuel dissolved in a circulating liquid, was developed for powering airplanes.

The submarine reactor made 550°F

heat, not as hot as a coal fire, but sufficiently hot enough to boil water for

powering steam turbines. The

airplane reactor

had to provide

1,300°F heat, hot

enough to duplicate jet fuel burning in a turbojet engine. It also had

to largely duplicate a jet engine's quick controllability, something solid rod uranium

reactors cannot do. Controllability analysis: Stability

Abstract,

Full 51 page

pdf

The submarine reactor made 550°F

heat, not as hot as a coal fire, but sufficiently hot enough to boil water for

powering steam turbines. The

airplane reactor

had to provide

1,300°F heat, hot

enough to duplicate jet fuel burning in a turbojet engine. It also had

to largely duplicate a jet engine's quick controllability, something solid rod uranium

reactors cannot do. Controllability analysis: Stability

Abstract,

Full 51 page

pdf

Basically a pot, a pump and a pipe, molten salt reactors are kitchen utensil simple, unpressurized, and naturally safe. Since molten salt reactors are hot enough to replace jet fuel, they are also hot enough to replace coal. Back then, no one saw a reason to replace either jet fuel or coal. So the airplane reactor was put on the shelf, and we continued to build the less efficient and more complicated uranium reactors to make electricity.

About Thorium as a nuclear fuel. Unlike uranium which will fission directly, thorium needs to be converted to a synthetic uranium before it will fission. That, plus the fact that thorium was known to have little or no weapons potential, was a big drawback at the height of the Cold War. So, like the molten salt reactor, thorium was abandoned.

Recycling power plants.

This means coal-burning power plant boilers have a 1,300°F nuclear replacement

boiler waiting in the wings, a

thorium-fueled

molten salt reactor

(MSR). Extremely simple and naturally safe, the MSR has been

built,

tested

at full heat, and

Here

is the world's chance to build a safer,

cleaner, more useful type of reactor incorporating what we have learned from the

earlier types. From a user's standpoint, it would be like going from

candles, with all their weaknesses and dangers, to electric light bulbs, far more

useful and less dangerous.

This brings us to another fact. The

combination of far cheaper thorium nuclear fuel, far cheaper reactor, near zero nuclear waste,

intrinsically safe, and no

need for weapons material could obsolete

today's nuclear reactor business. Think about what digital cameras did to

giant Kodak.

To Recycling Coal Power Plants

Bottom Lines. Using average sizes, 300 coal-to-oil refineries producing 46,000 barrels a day of synthetic crude oil products is about 14 million barrels a day - about the amount of natural crude oil America is currently importing.

At $50 per barrel ($1.20 a gallon), that's $2.3 million per day or $840 million per year of additional gross revenue for a 1 gigaWatt coal power plant. Using 100% coal as CTL feedstock, at $68 per ton of coal, the 3 million tons of coal would cost about $200 million. Thorium to power 1 gigaWatt's worth of electricity generators would be between $50,000 and $3 million per year. Replacing some of the coal with cellulosic biofeedstock to make non-Global Warming vehicle fuel blends will change these numbers.

There is no limit on how much oil we can make this way. We can build and power as many "Mine-Mouth" coal, shale, oil sands, and lignite to oil refineries as we wish. These refineries are air cooled, and the thorium needed to power them will last us thousands of years.

No Americans would be harmed by this change.

How much will this contribute to ending Global Warming emissions? Electricity is the key to solving climate challenge .pdf

This is the

simplest, yet most comprehensive Energy Expansion and Global Warming mitigation plan ever put forth. It will:

1) Make America energy independent forever.

2) Make Americans as energy-rich as they wish to be with reliable energy.

3) Stabilize and reduce the cost of gasoline, diesel, and jet fuel.

4) Make gasoline, diesel, and jet fuel non-Global Warming without having

to change our cars, trucks, and airplanes or our fuel infrastructure one bit.

5) Far cheaper thorium will bring the production cost of electricity down, which will repower the growth of

industries and our economy.

6) End over 50% of ALL of America's Global Warming emissions immediately

without giving up anything.

7) Save the coal and railroad industries from economic destruction.

8) Create hundreds of thousands of new permanent high-paying skilled trade

jobs.

9) Enable our power plants to avoid costly carbon capture rebuilds.

10) Enable America to become an oil exporter again.

11) 100% of the land, railroad connections, 75% of the coal handling equipment

is already in place. The coal pulverizers can come from the now-nuclear

coal power plants.

12) All the plans to make this happen exist. We could begin tomorrow.

13) Any country in the world that has cellulosic biomass plus at least one of

the following: coal, shale oil, lignite, peat, natural gas, oil, oil sands or sludge can do this.

14) OPEC can sell their outrageously priced diminishing amounts of Global

Warming natural oil

elsewhere.

How this will unfold. The author suspects that Restoring America's Oil Independence will happen in several waves: First, we will see mine-mouth coal-to-oil refineries, perhaps without biofeedstock blends. Second, for both environmental and economic reasons, power plant coal boilers will be converted to liquid thorium boilers. Third, perhaps a decade later, the world will finally realize that Peak Oil + Global Warming can only be fully addressed by massive amounts of synthetic non-Global Warming biofuels made from biomass blended with some fossil feedstock. Coal will always have a substantial cost advantage in this feedstock competition.

The important thing to remember is that when our 300 largest coal burning power plants are de-coaled, we do not demolish and scrap out their coal handling systems. We will need them all. Again, to replace all the imported oil we need, we will have to use as much coal as we are now burning to make electricity.

________________________________________________________________________________________

________________________________________________________________________________________

This is not "Popular Mechanics" style vapor reactor, vapor fusion, vapor miracle stuff. This is history in the making. Be part of it.

Give your Congressional representatives an email or phone call:

http://www.contactingthecongress.org/

Please ask them to:

1) Restore molten salt reactor development funding to

DoE's Oak Ridge National Laboratories.

2) Restore

clean

nuclear powered coal-to-oil refinery

development funding to the Department of Energy.

________________________________________________________________________________________