Oil

Gusher !

Site

Map

Making Fossil Fuels Green

Map

Making Fossil Fuels Green

The Prize: Restoring America's Oil Independence

by

adding BioGasoline refineries to our largest coal power plants

An

environmentally-clean coal-to-oil refinery to make environmentally-clean vehicle

fuels.

Endless, Non-Global Warming BioGasoline.

(Left) If you notice, the

imported oil slice of our energy pie and the coal slice are about the

same size. We could convert our coal into synthetic crude oil to end imported

oil and regain our energy independence.

How?

(Right) It will take all our coal to replace all our imported oil, so we would

convert our 300 largest power plants to nuclear and then add coal-to-oil

refineries to the power plants to make the oil. The power plant's unneeded

coal transportation, handling, and pulverizing equipment would be reconnected to

the coal-to-oil refinery.

1)

Introduction: Restoring America's Oil Independence

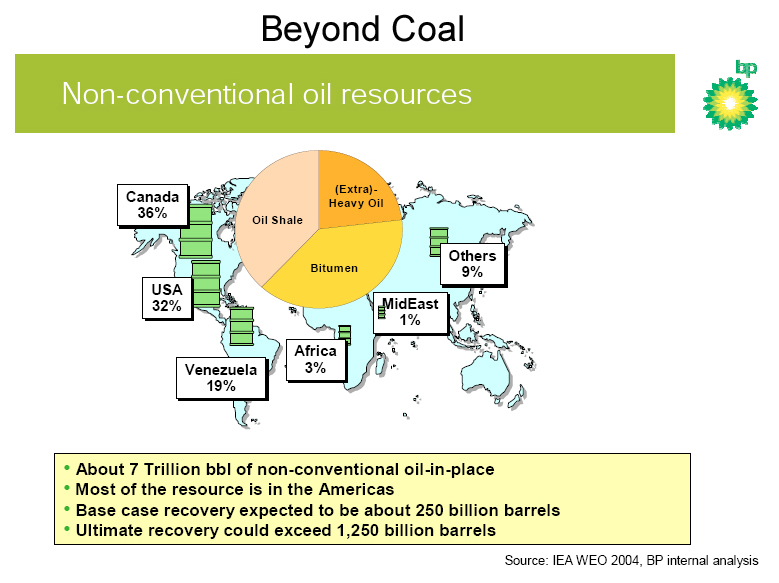

At the right, you can get an idea of

how much carbon there is available on Planet Earth. A relative tiny amount

of carbon is available in the form of Oil, Gas, Tars, and Shales. They are

extensions of coal, the big Kahuna of easily burned carbon.

We have enough carbon to make many

Global Warmings.

In about a 150 years, man has burned

a trillion barrels of oil. At first, oil was so easy to find and pump there were

"Oil Wars" between oil companies and oil prices plunged to as low as 10 cents a

barrel.

The world may be able to find and

pump another trillion barrels over the next 300 years. The scarcer, more

difficult to recover deposits of oil will become much more expensive to find and

pump. Our leaders are hoping pumped oil will stay below $200 a barrel for the

next 20 years.

Converting coal into oil is, in many

ways, completing what nature has been doing for 150 million years - taking coal

and cooking it into oil.

So it's not too surprising that oil

chemists figured out ways to duplicate the coal-to-oil conversion process on an

industrial scale about 100 years ago. Over the years, these processes have

been improved to the point where synthetic vehicle fuels can compete with pumped

oil whenever pumped oil costs more than about $50 per barrel.

The author is suggesting that

"Restoring America's Oil Independence" be a synthetic oil made from blends of coal, tars, natural gas,

and shales + cellulosic biomass in a process that does not harm the environment

in any way. From this synthetic biocrude oil, we can make as much

BioGasoline, BioDiesel, and BioJet Fuel as we want forever.

While the feedstocks are extremely

cheap, this process will consume very large amounts of electricity and heat.

If we use the 1,000 times cheaper energy metal, thorium, instead of coal, to

make electricity and heat, the costs and environmental impacts appear to remain

attractive.

The "Clean

Coal" to Oil Refinery Idea:

In May of 2008, Bonne Posma proposed

a nuclear-powered "Clean Coal-to-Oil" mine-mouth refinery. (

http://www.liquidcoal.com/pdf/reality%20energy_revised_050908.pdf )

Bonne suggested using a very high

temperature helium cooled pebble bed nuclear reactor then under development by

PBMR of South Africa.

Since that time, PBMR went out of

business with most of the technology being transferred to China. A

descendent of PBMR's reactor lives on in the form of China's 100 mW(e) Pebble

Bed reactor. About 20 of them are to be built at a electricity generating complex at

Rongcheng Shidaowan Nuclear Power Plant, China.

The author adapted Bonne's idea for

a nuclear powered clean coal-to-oil refinery to the thorium powered molten salt

reactor currently under development in China.

In the author's conceptual sketch

below, the Oak Ridge National Laboratories EBASCO molten salt reactor and its

confinement cell are being suggested.

Both concepts are "Dry" in the sense

that no water is used to cool the reactors. Also, the "Carbon Capture" and

sequestration component is explicit in the author's sketch.

(The United States shelved thorium

as a heat source along with the molten salt reactor in favor of the uranium +

plutonium fast breeder reactor, which showed much better weapons material

production potential, in 1972, at the height of the Cold War.)

Return to Contents

________________________________________________________________________________________

Part 1 The

Issues

________________________________________________________________________________________

2)

PEAK OIL, Our Gathering Energy Storm. $20 a gallon?

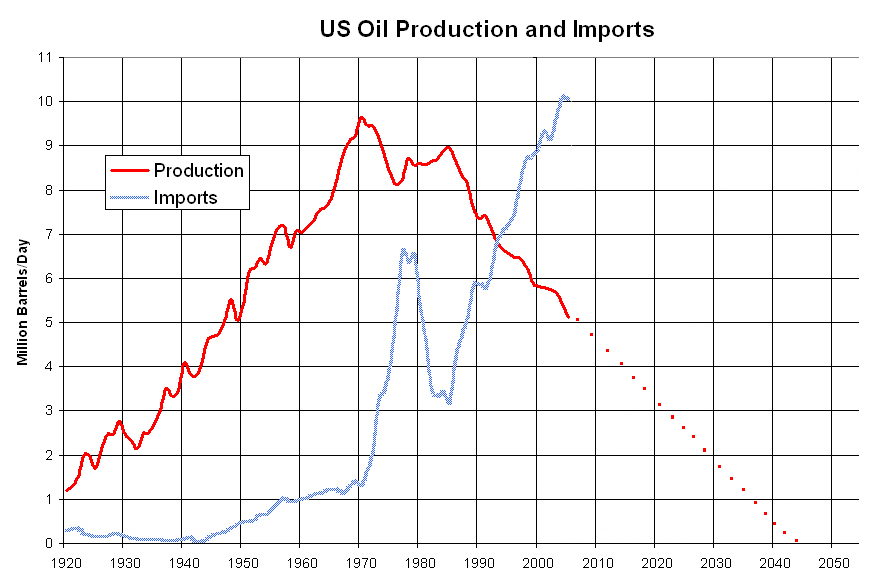

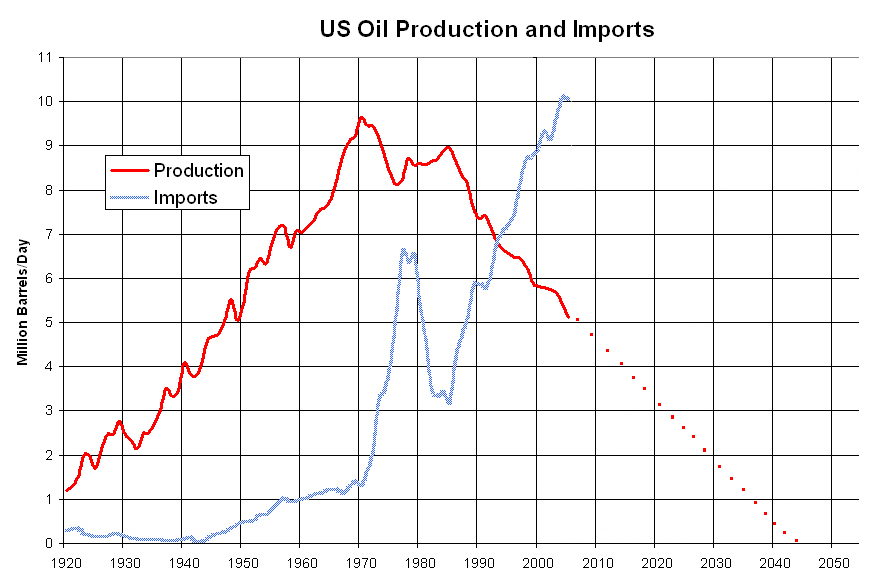

In the late 1960's, United States'

oil production (red line) was peaking, and oil imports (blue line) began to

shoot up. By 2005, oil imports were twice domestic oil production.

(Click to

enlarge this Wikipedia graph.)

(Click to

enlarge this Wikipedia graph.)

Despite having some of the

world's

largest reserves of fossil fuels, coal (US #1), natural gas (US #5), oil

sands (US #4), and shale oil (US #1), we are importing almost 300 billion

dollars worth of oil every year, 1/3 of our entire trade deficit. The U.S.

is 14th in pumpable oil reserves, 3rd in oil pumping.

We are pumping hard and

will

run out soon. Despite all the oil company "Happy Talk" we are getting on TV

about America's oil abundance, U.S. oil wells have been steadily running down

for over 40 years. A simple projection of the red line says the United States'

oil reserves will be almost bone dry by about 2045.

The United States is now consuming 243

barrels of oil per second.

American

geophysicist M. King Hubbert accurately predicted the 1970

U.S. oil peak in

1956. Others are saying

Global Peak

oil is probably happening now. Chart:

American

geophysicist M. King Hubbert accurately predicted the 1970

U.S. oil peak in

1956. Others are saying

Global Peak

oil is probably happening now. Chart:  Unconventional

oil such as oil sands are picking up the shortfall. Chart:

Unconventional

oil such as oil sands are picking up the shortfall. Chart:

OIL

- Peak oil debate losing relevance due to new upstream technology .pdf

OIL

- Peak oil debate losing relevance due to new upstream technology .pdf

Here is what the oil companies don't want you to pick up on:

(Thank you,

Kurt Cobb )

(Thank you,

Kurt Cobb )

Losing control of your energy

sources means losing control of your economy. We know that oil price spikes

have been associated with 10 of the last 11 economic recessions. Worse, war has

already mixed the blood of many Americans with our imported oil.

Reality

Check: Altona energy (UK)

believes it can supply vehicle-ready diesel at $53 a barrel ($1.26 per gallon)

from coal, by burning coal with carbon capture, at Arckaringa, Australia.

Reality Check: Natural Gas can also be used

as Gas-to-Oil feedstock but gas does not promise the same vehicle fuel cost

reductions as coal.

Shell's Pearl

Return to Contents

3)

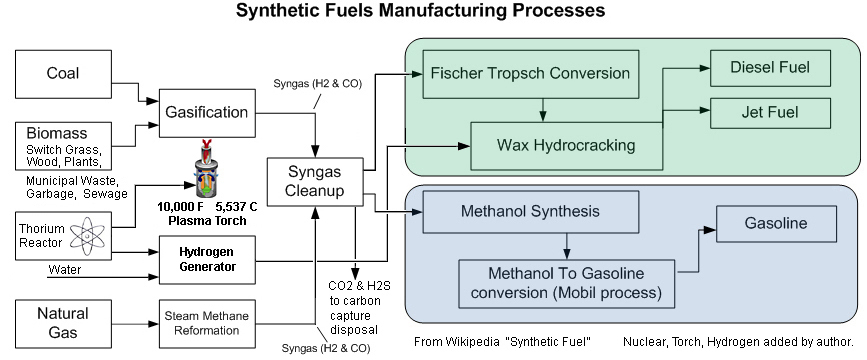

COAL-TO-LIQUIDS (CTL) Synthetic

Oil: Making Our Own Oil From Our Own Coal

Eventually, the United States

will begin the job of replacing its imported oil with oil made from our own

coal, natural gas, oil sands, and oil shale.

We are not alone. The South

Africans have been burning coal to convert coal to oil and other liquids (Coal

To Liquids or CTL) - mostly diesel - for over 30 years,

South Africa now has the capacity of producing over 160,000 barrels per day

(BPD). South Africa's

SASOL company

alone has produced over 1.5 billion barrels of oil this way. Oil poor China is

also investing heavily in CTL (Their first plant,

Shenhua, will be

60,000 BPD).

Australia is considering a 10

million barrels per year project called Arckaringa. Germany had more than

50 coal-to-oil refineries during WWll. US, UK, and South Korea have small pilot

plants and a global total of 600,000 BPD capacity are expected to be on line by the end of 2011.

CTL - US

Synthetic Fuel From Coal - DOE .pdf

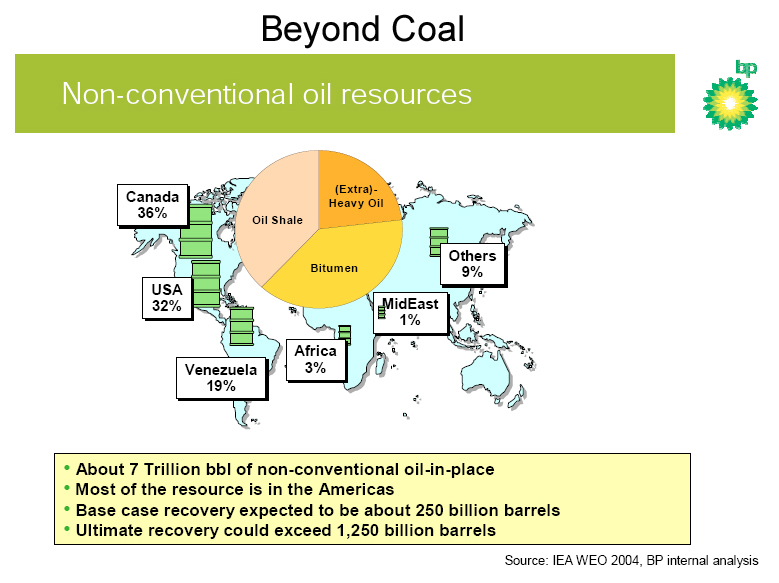

In addition to Coal-to-Liquids, a

larger volume of crude oil is being produced from unconventional sources such as

oil sands (Canada, 1.4 million BPD) and oil sludge (Venezuela, 500,000 BPD).

Like synthetic crude oil from coal, current manufacturing methods for

unconventional crude oil produce a crude oil that causes at least twice the

Global Warming emissions as pumped crude oil.

Interested in coal-to-liquids?

Here is an excellent free downloadable pdf book made available as a public

service from the RAND Corporation:

Summary Only:

http://www.rand.org/content/dam/rand/pubs/monographs/2008/RAND_MG754.sum.pdf

Book + Summary:

http://www.rand.org/content/dam/rand/pubs/monographs/2008/RAND_MG754.pdf

Quick Coal-to-Liquids Overview:

http://en.wikipedia.org/wiki/Synthetic_fuel

<G

Return to Contents

4)

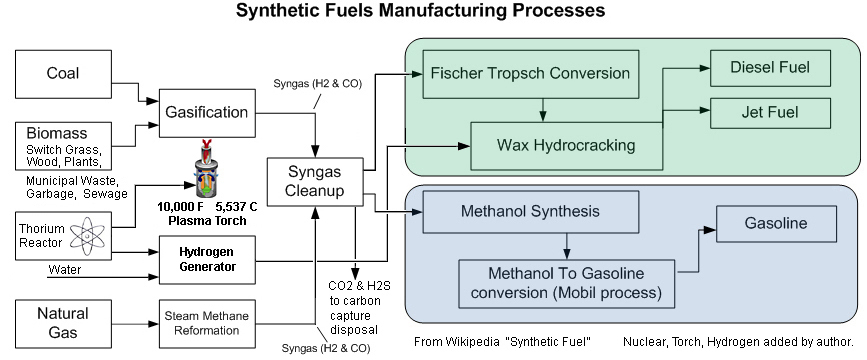

SYNTHETIC

BioGasoline from Blends of U.S. Coal + Biomass

"Carbon-Neutral" means

burning the biogasoline neither hurts nor helps Global Warming.

There are several

general approaches: Biomass

only; Blended coal or natural gas + biomass; Completely synthetic.

1) Biomass

Only

Ethanol, Algae, BioDiesel, Cooking

Oils, Plant Oils,

etc., processed by fermentation and distillation,

by using fossil fuel energy.

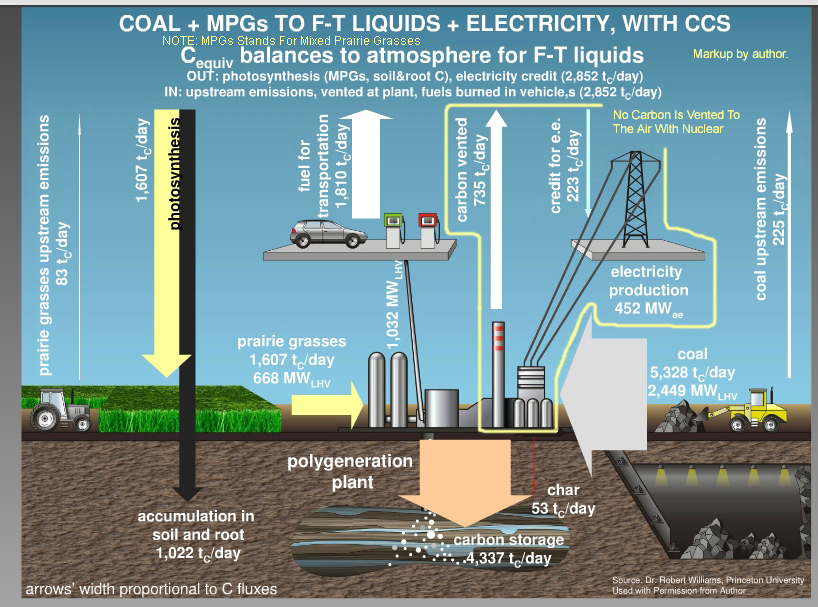

2) Blended

Coal or Natural Gas + Biomass Synthetic

Coal + Biomass

refining technologies for cheap, environmentally friendly transportation fuels,

processed by clean nuclear energy (in this web site).

"Indirect" conversion of coal

into synthetic oil opens the door to environmentally friendly gasolines,

diesels, and jet fuels. By using Liquid Thorium nuclear energy to power the

"Coal and Biomass to Liquid" (CBTL) process, a substantial additional Global

Warming benefit can be achieved. Chart:

"Carbon-neutral" synthetic

gasoline, diesel, and jet fuel may be possible

when coal feedstock + certain biofuel feedstocks + carbon capture + nuclear heat

are combined. Results from some blends using coal heat + carbon capture

technology are very promising. Chart: From:

http://en.wikipedia.org/wiki/Synthetic_fuel

From:

http://en.wikipedia.org/wiki/Synthetic_fuel

CTL - Affordable, Low-Carbon Diesel Fuel from Domestic Coal and Biomass - CBTL

Final Report .pdf

If the coal + biofuel blend folks

are correct, it may be possible to come up with identical or better (and

cheaper) gasoline, diesel, and jet fuels having net zero lifecycle CO2

emissions with surprisingly small percentages of biofuel in the blend if

liquid thorium instead of coal burning is used to power the CTL conversion and

if carbon capture technology is used to prevent the CO2

emissions normally associated with the CTL process from being vented to the air.

In addition to cellulosic biomass

feedstock (grasses, woods), municipal solid wastes (MSW) and sewage are

potential sources of carbon-neutral carbon.

Plasma arc

waste disposal, which gasifies municipal solid wastes using a device called

a plasma converter, are a practical source of carbon-neutral feedstock producer

gas. The useable syngas is drawn off the top off the gassifier, the slag and

metals from the bottom. The non-metal solid wastes can be added to the wastes

from the coal gassifier and placed in played-out mine shafts.

America's sewage alone can supply

almost 10% worth of gasifiable carbon-neutral feedstock for America's vehicles.

In these feedstock blends, coal is used as the sequestered (plant root) carbon

component (See "Comparing Fuels.")

http://www.corebiofuel.com/ Core

Biofuel produces a 100% cellulosic biogasoline that is "greener" than

carbon-neutral but burns to provide the energy to drive the process, thus

reducing the "green-ness" of the final product.

http://www.sundropfuels.com/

Sundrop fuels are building a cellulosic biomass +

natural gas synthesis plant that should be able to make exactly carbon-neutral

biogasoline at a better than natural crude gasoline price.

What is being suggested by

Restoring America's Oil Independence is far "Greener," than Core's or Sundrop's technology since

the energy needed to make its biogasoline will come from extremely cheap CO2-free

nuclear. It can blend coal + biomass for a variety of "green" or cheap

biogasolines. (See "Comparing Fuels," right.)

3) Completely

Synthetic

Beyond Coal-to-Oil: The "Green

Freedom" papers: Green Freedom .pdf

Green Freedom -

Martin_AEC_2008_revised.pdf

This approach has zero fossil fuel

components, relies on extremely large amounts of energy from nuclear.

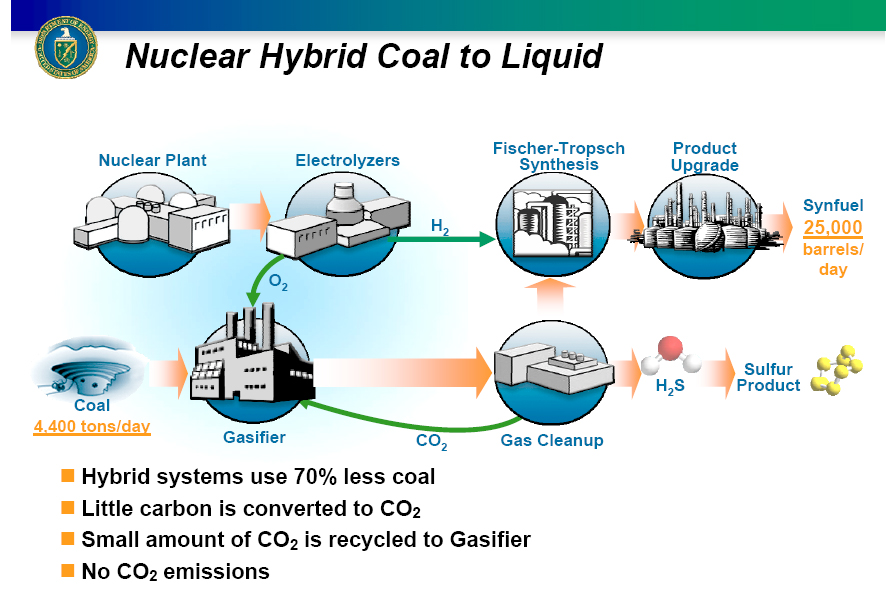

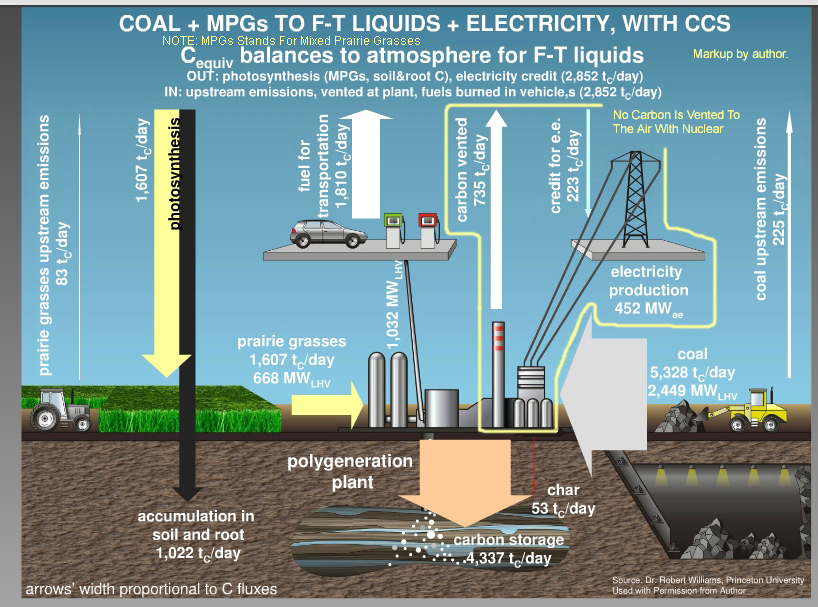

5)

A

Zero-Emissions Coal + Biomass Synthetic Oil Refinery

A Zero-Emissions Synthetic Oil Refinery

for Making Net-Zero Emissions Transportation Fuels

This is the difficult part.

By using high temperature nuclear heat instead of coal heat to make

coal-to-oil, you are painting with a different palette.

The RAND Corporation studies

indicate that complete capture and disposal of CO2

emissions would add less than $5 to a barrel of CTL oil, burning coal to make

oil.

Co-generation of electricity by

burning unusable process gas is the major source of CTL's Global Warming

emissions. Since this is no longer acceptable, this gas must be kept inside the

product stream or become part of the CCS disposal stream.

If coal-to-oil is to be done

squeaky-clean, we will have to use high temperature nuclear heat and capture the

inevitable streams of CO2

and H2S.

This will take more processing, more expensive heating equipment such as

10,000°F

Westinghouse plasma electric

torches with 1,000 hour electrode life to vaporize the coal feedstock.  (

About (pdf)

Applications

(pdf) ) But it can be done. The author has a 2002 Westinghouse

Plasma Corporation paper about a "next-generation" Plasma Gasification Reactor

study with a capacity of 360 tons/day.

(

About (pdf)

Applications

(pdf) ) But it can be done. The author has a 2002 Westinghouse

Plasma Corporation paper about a "next-generation" Plasma Gasification Reactor

study with a capacity of 360 tons/day.

The biggest downside will be the

additional energy needed to make "clean" happen. But, heat from thorium is so

cheap it is almost free. That's the trade-off.

And nuclear promises even cleaner, more energetic synthetic

fuels (higher miles-per-gallon) than today's fuels if we can manage to cleanly

obtain the hydrogen available from water to upgrade the oil molecule further.

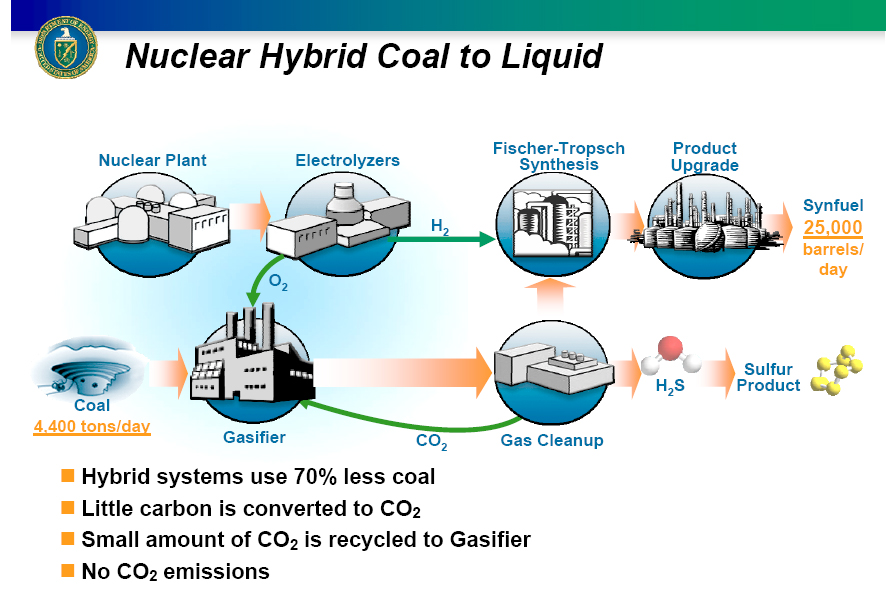

"A nuclear source of hydrogen coupled with nuclear process heat would more than

double the amount of liquid hydrocarbons from the coal and eliminate most CO

2

emissions from the process." -

http://world-nuclear.org/info/inf116_processheat.html

The coal-to-oil conversion

process produces ultra-clean clean fuels with all of coal's solid pollutants

being trapped in the coal's solid waste char and gas pollutants captured during

refining. Coal-to-oil conversion is a well-known process, and its environmental

aspects are well-documented by many sources. (Click to enlarge.)

Environmental impact.

Converting our 286 largest power plants from coal to

nuclear to make both electricity and synthetic oil would end about 40% of ALL

U.S. Global Warming emissions. If the solid waste, CO2,

and H2S

(sulfur) from the coal refining process is sequestered, then there should be no

objections about use of ultra-clean synfuels produced from coal.

Replacing all of America's

imported oil would consume a little

more than ALL the coal the U.S. is currently burning to make electricity.

To make this all environmentally

sane, the EPA should make the allowable combined power plant and coal-to-oil

refinery emissions equal to or lower than had the power plant alone converted to

"Carbon Capture and Sequestration" emissions control instead, i.e., an 80% or

more reduction in ALL emissions, including CO2

(carbon dioxide). CCS backgrounder:

http://en.wikipedia.org/wiki/Carbon_capture_and_storage

More on the zero-emissions

synthetic oil refinery page >

Return to Contents

6)

A

Water-Splitting Hydrogen Generator to Upgrade BioCrude to Vehicle Fuels

Upgrading and refining synthetic

crude oil made from coal and biomass. Crude oil made from coal + biomass

from all sorts of sources will be very pure but composed of a wide variety of

different molecule weights that will have to be broken down (cracked) into

vehicle-ready fuels. The 1,300°F heat from the reactor will hit the spot for

hydrocracking of some synthetic oil molecules which, in a conventional oil refinery, uses hydrogen from

natural gas, a process that produces large amounts of carbon dioxide.

Small amounts of hydrogen can be

obtained without Global Warming emissions from electrolyzers. If large

amounts of hydrogen are needed, the extremely high temperature water-splitting

sulfur-iodine process will have to be used. The reactor's 1,300°F heat

isn't quite hot enough to drive the water-splitting process, but when another

350°F is added via electrical heat booster elements, the FLiBe heat transfer

salt should be hot enough to get the job

done. Both electrolyzers and calrod heat boosters consume a lot of

electricity. Being located at the power plant, they avoid costly

electricity transmission costs.

http://en.wikipedia.org/wiki/Oil_refinery

http://en.wikipedia.org/wiki/Hydrocracking#Hydrocracking

http://en.wikipedia.org/wiki/Algae_fuel#Biogasoline

Return to Contents

7)

Endless Heat Is

Necessary To Make Endless Oil

The US has virtually

endless

feedstock for making oil, but we also need endless, clean, very hot heat to

make endless clean oil. While we do have 27% of all the world's coal, we can't

burn coal or natural gas because they are our feedstocks, it is becoming obvious

coal is so valuable we simply can't afford to burn coal to make the necessary

heat for producing electricity or synthetic oil. Coal reserves expectancies

chart:  Windmills are clean and endless but don't make heat. That leaves only nuclear

heat. (Click to enlarge image at right.)

Windmills are clean and endless but don't make heat. That leaves only nuclear

heat. (Click to enlarge image at right.)

THE BAD

NEWS: The nuclear reactors we are using today are

simply not hot enough at 550°F

to do anything much beyond boiling water to make

electricity.

THE GOOD NEWS:

Another type of reactor, the air cooled 1,300°F high

temperature Molten

Salt Reactor is hot enough to replace the coal being burned in power

plants and also to convert that coal into crude oil. This much safer reactor

has little in common with today's reactor.

Reality

Check: At the present time, there are no molten salt reactors in

operation. The US government abandoned molten salt reactors about 1972 when

it was understood that thorium had near-zero nuclear weapons value. That was

then, this is now. You wouldn't be reading this if liquid thorium were not

being "taken back off the shelf" in many places for many reasons.

For the purposes of showcasing a

Molten Salt Reactor on this web site, the author has chosen the 1 gigaWatt

(electrical) [2.5 gigaWatt (thermal) reactor and confinement cell combination

designed by EBASCO.

Molten salt

reactors have little in common in physical size, cost, or the way they work

when compared to the solid uranium reactors in worldwide use today. The most

commonly suggested nuclear fuel for this type of reactor is

thorium.  http://en.wikipedia.org/wiki/Molten_salt_reactor

http://en.wikipedia.org/wiki/Molten_salt_reactor

Top

U.S. molten salt web site:

http://energyfromthorium.com/

Return to Contents

8)

What About

Stripper and Dirty Oil (Brine and Bromine) Wells?

http://en.wikipedia.org/wiki/Stripper_well

http://stripperwells.com/

There are over 420,000 of these wells in

the United States, they average 2.2 barrels per day, and together

they produce nearly 915,000 barrels of oil per day, 18 percent of

U.S. production.

9)

Adding a Coal + Biomass Oil Refinery to a Large Converted Coal Burning Power

Plant

Taking advantage of already-existing coal

handling facilities.

By taking advantage of molten salt's

heat transfer properties, (molten

salt vs. water), we could transfer the other half of the molten salt

reactor's heat to the adjacent coal-to-oil refinery to convert the coal that is

no longer being burned to make electricity into 50,000 barrels of diesel fuel or

biocrude

per day.

The

coal-to-oil facility would be about the same size as the power plant when

you subtract the heating and coal handling equipment. The molten salt reactor

would be located between the electricity plant and the coal yard, with the

coal-to-oil plant located further out, between the reactor and the far side of

the coal yard for fire isolation. A

pipeline would carry the oil away from the CTL plant to either a nearby crude oil

pipeline or a rail car filling station located adjacent to the coal train dump

loop.

The

coal-to-oil facility would be about the same size as the power plant when

you subtract the heating and coal handling equipment. The molten salt reactor

would be located between the electricity plant and the coal yard, with the

coal-to-oil plant located further out, between the reactor and the far side of

the coal yard for fire isolation. A

pipeline would carry the oil away from the CTL plant to either a nearby crude oil

pipeline or a rail car filling station located adjacent to the coal train dump

loop.

The coal-to-oil refinery would

make use of the power plant's coal handling facilities and cooling water but not

the coal equipment inside the power plant. 15,000 tons of coal per day

would come in (150 100-ton railroad cars). Going out would be 12,000 tons of

oils to market, 3,000 tons of solid waste back to the coal mine. Being nuclear

powered, the refinery would make no air pollution or Global Warming emissions.

The CO2

and H2S

made by the CTL process would be piped away for disposal. A railroad tank car

holds a maximum of 34,500 gallons or 820 barrels, so 50,000 barrels of oil would

make a 70 tank-car long train plus another 30 coal-car train to remove the coal

ash.

Reality

Check: There are many papers for nuclear heat assisted

coal-to-liquids processes but nothing definite at this time. Most are centered

around the small "Pebble Bed" high temperature reactor. China is making a

number of 100 mWe pebble bed reactor units for their Rongcheng electricity

generation complex.

(Refinery numbers thanks to

http://www.liquidcoal.com/ .) See

also World Coal Association

Coal-to-Liquids.

Return to Contents

________________________________________________________________________________________

Part 2

The Economics

________________________________________________________________________________________

10)

ECONOMICS: Cheaper Electricity, Crude Oil, Coal Mine Mouth Oil

ECONOMICS,

Part 1: Electricity At 1/66th Today's Production Cost?

The economics of using

thorium-fueled molten salt heat instead of coal heat to make electricity.

(About 40% of the "Energy Charge" on your electricity bill.)

Cost of thorium vs. coal for a power

plant to make 1 gigaWatt-year of electricity: Thorium: $50,000;

Coal: $200,000,000.

It takes about 3 million tons of

coal (costing 200 million dollars at $68/ton, delivered) to make one

gigaWatt-year of electricity.

"Once up and running, 800 kg of thorium [1,760

pounds] - costing about 50,000 dollars [US$28.40/lb] - would produce one

gigaWatt-year of electricity." (Stated by Dr. David LeBlanc, Physics Department,

Carleton University, Ottawa, in a Google lecture on Feb 19, 2009.)

d_leblanc@rogers.com

His Google lecture:

http://www.youtube.com/watch?v=8F0tUDJ35So

So, using June 10, 2011 coal prices,

heat from simple thorium would be about 4,000 times cheaper than heat from

coal.

Reality

Check: The author is suggesting using the

Denatured

(pdf) thorium fueled molten salt reactor protocol rather than pure thorium, so

the actual annual fuel costs (with uranium ore at $100/kg, $45/lb) for the

reactor being discussed on this web site would increase to about

$3 million per gigaWatt-year or about 66 times cheaper than coal. The

denatured fuel protocol is used to zero-out as much as is possible the fuel's

potential for proliferation and terrorist uses.

With a margin that large, using a

denatured thorium fuel protocol instead of coal to make electricity is highly

attractive.

Natural gas is about twice as

expensive as coal.

ECONOMICS,

Part 2: Synthetic Oil Forever At 1/8 Of Today's Natural Oil Cost?

The economics of converting coal

to oil to replace imported oil.

At about

$2 per million British Thermal

Units (30.8 million BTU per ton at $68 per ton), the energy content in US coal

is priced at the equivalent of about $13

per barrel of oil (5.8 million BTU), meaning that coal is about 1/8 of the cost

of internationally traded crude oil, such as Brent ($104 on 10/1/2011).

(Natural gas is about $4 per million BTU.)

With a margin that large, using coal

instead of oil to make vehicle fuel is highly attractive.

Reality

Check: Altona energy (UK)

believes it can supply vehicle-ready diesel at $53 a barrel ($1.26 per gallon)

from coal, by burning coal, at Arckaringa, Australia.

ECONOMICS,

Part 3: Mine Mouth or Power Plant Coal Yard?

The cost of transporting coal

from the mine to the power plant in the United States is roughly 25% the

cost of the delivered coal. This would make "Mine-Mouth" coal about $50 per ton

or about $100 million cheaper per year than delivered at the power plant for a

50,000 bbl/d CTL plant. Mine-mouth coal refining also makes disposing of the

solid waste (about 1/5 the volume of the coal removed from the mine) back into

the mine extremely cheap. (Click on image to enlarge.)

Summary

Repowered Power

Plants Can Produce BOTH Electricity and CTL Oil

We have to import about 11 million

barrels of oil every day. This drains America of about 250 billion dollars

every year. Coal burning power plants should be modified to make their

electricity from thorium nuclear and to use their coal and biomass as feedstock

for cheap, environmentally friendly synthetic gasoline, diesel, and jet fuel.

Thorium-fueled

molten salt reactors are technology's

unharvested low-hanging fruit.

Return to Contents

________________________________________________________________________________________

Part 3

Recycling Power Plants and Adding Refineries

________________________________________________________________________________________

12)

Recycling our largest coal burning power plants into nuclear power plants.

To replace the

11 million barrels of oil per day we are importing,

it will take 220 50-thousand barrels per day coal-to-liquids refineries.

If you look at the RAND CTL paper,

220 power plants seems like an outrageous concept. But they are thinking inside

the coal box.

America's electricity: Out of 4

trillion kiloWatt-hours produced in America in 2009

Coal produced 1.800 trillion kiloWatt-hours of electricity;

natural gas 0.920 trillion kiloWatt-hours;

nuclear 0.806 trillion kiloWatt-hours; and

oil 0.040 trillion kiloWatt-hours of electricity.

Plant Selection: According

to CARMA (a carbon emissions monitoring web

site, 2007 data), the United States has a total of 5,211 CO2

emitting power plants. The author divided them into four groups: "Mega,"

"Midi," "Mini," and "Micro." Their CO2

emissions distribution is shown below. Most of the "Mega" plants are coal

burners.

Emissions Tons CO2

per yr Count Tons CO2

Total Tons CO2

Average Comment

"Mega" Over 2,585,125 286

2,107,121,906 7,393,410 (About 40% of United States' entire

5.4 billion ton annual CO2

total.)

"Midi" Over 97,426 983

670,955,785 682,559 (Average Midi's emit about 11 times

less than average Megas.)

"Mini" Over 0 3,942

37,587,796 9,535 (Many rural diesel power plants in

this group.)

"Micro" Unknown or None

4,263

(Hydro, does not include wind and solar lull "shadowing" by fossil.)

The average "mega" coal burning

power plant is emitting about 775 times more CO2

than the average "mini" plant. There's

no way you can say the EPA is being fair - or even intelligent - by treating all

of them the same. If you have a bunch of problems that take similar effort to

fix, you get the biggest payback by fixing the worst first.

being fair - or even intelligent - by treating all

of them the same. If you have a bunch of problems that take similar effort to

fix, you get the biggest payback by fixing the worst first.

From CARMA's data base, the first

U.S. plant to fix is Georgia Power Co's Scherer plant. In 2007, it produced

27,200,000 tons of CO2.

That's 3.7 times as much CO2

as the average "mega" sized plant and 40 times as much CO2

as the average American "midi" power plant.

This way,

we would be playing fair with America's thousands of small "midi" and "mini"

power plants and their several hundred thousand skilled trade workers.

Recycling the 983 smaller "midi"

coal burning power plants.

(Left) This rural 55 megawatt power plant is typical of the hundreds of small power plants caught

in the environmental squeeze created by our "one EPA rule fits all" government.

These regulations could cause 40% of our coal burning power plants to go out of

business in the next 10 years taking about 100,000 good-paying skilled trades

jobs with them. - - Power Magazine, May 2011

Too small to convert to nuclear,

too vital to America's economy to kill, an excellent compromise would be to allow them

to repower with "Combined Cycle Natural Gas" (Right). A 30% efficient

coal burning power plant, when converted to combined cycle natural gas can

approach 50% overall efficiency using a fuel that produces only 60% of the

carbon dioxide per kilowatt hour as coal. This is a great way to increase

power generating capacity while reducing CO2

emissions.

Later, when the Chinese version of

our molten salt reactor is being sold here, the natural gas combustor in the

turbine can be swapped out with a

salt heat exchanger and the power plant can go zero CO2

on thorium, a fuel that can be as much as 7,000 times cheaper than coal.

Thorium liquid reactors have

little in common with today's reactors, produce less than 1% of their

nuclear waste, are the most energy-dense of all nuclear reactors, and are hot

enough to replace coal's red-hot fire - something today's conventional reactors

cannot do. We have reached the performance limits of today's reactors. They

have not brought humanity an era of greatly increased amounts of electricity

"too cheap to meter."

Fortunes will be made

converting the world's thousands of coal burning power plant boilers to combined

cycle natural gas, and later, liquid thorium boilers. The two "Fuel

Switch" conversion examples (below) show how Liquid Thorium could be efficiently

integrated into most fossil fuel power

plants, large soon, small later. The United States has become a very risk-adverse country, not a place

where entrepreneurs will want to do new things. In addition to the almost 300

candidate power plants in the United States, there are at least 1,000 similar

coal burning power plants spread around the world.

This link should take you to

a list of them elsewhere on this web site.

The "Top Ten"

candidates for the first U.S. nuclear Coal + Biomass to Biocrude Oil refinery.

|

|

|

|

|

|

|

Rank |

Power Plant Name |

2007 Tons CO2 |

State |

City |

|

|

|

|

|

|

|

1 |

RW SCHERER |

27,200,000

|

Georgia |

Juliette @

33 03 37N 83 48 34W Elev. 455' |

|

2 |

MILLER |

23,700,000

|

Alabama |

Quinton |

|

3 |

BOWEN |

23,200,000

|

Georgia |

Cartersville |

|

4 |

GIBSON |

22,400,000

|

Indiana |

Owensville |

|

5 |

MARTIN LAKE |

21,800,000

|

Texas |

Tatum |

|

6 |

WA PARISH |

20,900,000

|

Texas |

Thompsons |

|

7 |

MONROE (MI) |

20,600,000

|

Michigan |

Monroe |

|

8 |

NAVAJO |

20,200,000

|

Arizona |

Page |

|

9 |

GAVIN |

19,100,000

|

Ohio |

Cheshire |

|

10 |

LABADIE |

18,700,000

|

Missouri |

Labadie |

Return to Contents

13)

RW Scherer Quad 880 megaWatt

(3520 total) coal burning power plant.

(There is nothing about RW Scherer on

this web site that is not available on the internet.)

A suggestion about how one might

nuclear repower and add a coal-to-oil refinery facility.

Listed as the largest producer of

Global Warming CO2

in the United States. "The coal used at the Scherer plant comes

from Wyoming's Powder River Basin, and is delivered by BNSF from the

mines to Memphis, Tennessee. From there, it is taken to the plant by

Norfolk Southern in unit trains of up to 124 cars. Currently, at

least three and as many as five trains a day are unloaded at

Scherer. The trains use an air-dump system and are unloaded from the

bottom of the cars while passing over the unloading trestle. They do

not stop while unloading, and are usually unloaded in around

90 minutes." - - Wikipedia

(Stacks are about 1,000 feet tall.)

-- About 50,000 tons of coal

every day. Enough for three 50,000 barrels per day coal-to-oil refineries

or 150,000 bbl per day (or 6.3 million gallons per day). The United States

is burning about 243 barrels of crude per second (21,000,000 bbl/day), so that

would be about 10 minutes of oil per day for the entire United States. RW

Scherer alone would be making about the same amount of coal-to-oil as all the

CTL refineries in South Africa (160,000 bbl/day).

A single EBASCO liquid thorium

reactor is designed for 1,000 megaWatts (e). RW Scherer has four 880 MW

generators, so would require 4 EBASCO underground reactors because it is not on

navigable water. (See "Mine-Mouth" conceptual sketch below). The

author has no idea at this time how much heat it will take to turn 50,000 tons

of coal into 150,000 barrels (21,000 tons) of crude and how much additional heat

would be required to make the hydrogen needed to upgrade that crude to

vehicle-ready fuel. Let's plug in one additional EBASCO-size reactor.

Plant

Scherer to install coal reburn system

GE Power Systems also recently announced several U.S.

projects, including a contract to supply coal reburn

systems for units 1 and 2 at Plant Scherer near

Juliette, GA. To be installed in the spring of 2001 and

2002 respectively, Southern Company subsidiary, Georgia

Power—the plant operator—expects the coal reburn system

to significantly reduce NOx emissions.

The units at

Plant Scherer have an 870 MW capacity with coal burning,

tangentially fired boilers and GE steam turbines,

possibly "G" Series, (Left).

According to Anthony

James, plant manager at Plant Scherer, the coal reburn

systems will allow it to meet its NOx reduction goals.

"We are excited about this project. It will reinforce

Southern Company's position as one of the leaders in the

application of new power generation technology."

(Right) General

Electric coal steam turbine. About 2,470 psi (170 bar)

and 1,050°F (565°C).

General layout of new underground

silo power plant

reactors plus

the new coal-to-oil refinery and its reactor.

Coal-burning power plant boilers have an

equally hot

nuclear replacement boiler waiting in the wings, the

thorium-fueled

molten salt reactor.

Extremely simple and naturally safe, it has been

built,

tested

at full heat, and

well-documented

by Oak Ridge National Laboratories, and is ready for

final user design. Unlike today's reactors, this

reactor's final user design was not "Cast in Concrete"

by your grandfather. Here is the world's chance to

make a safer, cleaner, more useful type of reactor

incorporating what we have learned from the earlier

types. From a user's standpoint, it would be like

going from candles, with all their weaknesses and

dangers, to electric light bulbs, far more useful, far

less dangerous.

Oak Ridge National

Laboratories had final user design studies for this type

of reactor made in both 1965 and 1972. Both were

for a 1,000 megaWatt (e) molten salt converter reactor.

The 1965 study was ORNL-TM-1060.

The 1972 study was by a team

of senior technical personnel put together by EBASCO

Services, Inc. The team included personnel from

Babcock & Wilcox, Continental Oil Co., Inc., Union

Carbide, Cabot Corp., and Byron-Jackson. It is

archived under TID-26156. Obtaining this document

is the best possible initial introduction to the design

details of the molten salt converter reactor being

suggested here. The author would be delighted to

point out additional such documents to interested

individuals.

Simply Google TID-26156

to download and save this free, extremely detailed 234

page pdf document.

There are about 40 three-line per citation pages of free downloadable ORNL

reports on molten salt reactor technology available at

http://www.energyfromthorium.com/pdf/ (Kirk Sorensen's web site ORNL

collection.)

(Left) Overall view of RW

Scherer plant site and synthetic coal-to-oil refinery

location (rectangle, green).

Coal-To-Liquids refinery and its reactor is located on other side of coal yard for

fire isolation. Click on images for

larger view.

(Left and below) The

liquid thorium reactors (round, blue) and steam

generator buildings (square, red) on gray gravel base;

plus steam lines (red). Size reflects the original

EBASCO confinement cell design. The unpressurized

reactor tank itself is about 30 feet in diameter; the

heavy radiation confinement cell, 70 feet; and the

natural air convection cooling jacket brings the overall

diameter of the blue reactor symbol to about 90 feet.

(Right) Closer view of RW

Scherer plant.

If desired, the original

boiler and coal equipment could be left in place and

selector valves at the coal boiler discharge could make it a

dual-fuel steam power plant.

(Left) Conceptual sketch

showing how new underground silo reactor would be connected to existing

superheated steam turbogenerator. Click to

enlarge, click again to enlarge more.

Return to Contents

________________________________________________________________________________________

14)

The Technology Modules In

Greater Detail

A variety of technologies were combined on this web page to

assemble the "Making Fossil Fuels Green" concepts.

Everything used here has been

invented, much of it is already in use in other commercial areas or in final

commercial development by other countries.

1)

THE NATURALLY SAFE, THORIUM-FUELED, MOLTEN SALT

REACTOR Because of its temperature, and the way it delivers

its heat, this is the only device mankind has at his disposal that can provide

the unique power needed to halt Global Warming.

Halting Global

Warming

2)

The EBASCO Reactor and its Confinement

Cell Assembly

3)

Barge Mounted Air Cooled Liquid Thorium Reactor Assembly

4)

Underground Silo Air Cooled Liquid

Thorium Reactor Assembly

5)

Stirling Air Turbine Electricity Generator

6)

CO2-Free Hydrogen from Water,

Coal, or Natural Gas for Upgrading Oil

(For wax hydrocracking to make diesel and jet fuel

from F-T syncrude.)

7)

Coal Mine-Mouth Waterless

Zero-Emissions Synthetic Oil Refinery

8)

Replacing Coal

Boilers With Thorium Boilers An economic alternative to retrofitting carbon

capture and sequestration equipment.

9)

Upgrading Existing Coal Burning

Power Plants to Nuclear

10)

A Zero-Emissions Synthetic

Oil Refinery making Net-Zero Emissions Transportation Fuel

Return to Contents

________________________________________________________________________________________

Reality Checks

________________________________________________________________________________________

15)

Reality Checks

Reality

Check: The power plant sketches on this web site show heat transfer

salt being used to transmit and divide up the reactor's thermal energy as if it

were electrical energy. This enables reactor modularity where a barge-mounted

reactor can be removed from its load and replaced with another reactor. This

feature is missing from today's nuclear power plants. This is an advanced

technology the author has never seen in use in a power plant. It might not

work, and/or heat transfer salt might cost too much to be practical.

There is a safety advantage in that

hot molten salt has no vapor pressure so there is no possibility of steam

explosions. An operational disadvantage is the salt must be drained into heated

"drain" tanks (blue in drawings below) any time the salt isn't being used or it

will freeze solid in its pipes. It contracts when it freezes, so it won't burst

the pipe as water would. A typical commercial heat transfer salt would be

Costal Chemical's "HITEC."

Heat transfer salts used inside nuclear reactors are

Flinak and

Flibe salts.

Heat transfer salt is currently in

use to gather heat from industrial size solar heat collectors and then to carry

the heat to a central electricity generator. (Right)

Reality

Check: (Below) In 1972, EBASCO designed a

1,000 megaWatt liquid

reactor power plant for a consortium of 15 mid-west electricity utilities

under Oak Ridge National Laboratories auspices. EBASCO engineered an improved

way to deliver nuclear heat while confining both radiation and the reactor's

heat. It was never built. The US government abandoned further work on

molten salt reactors in favor of the liquid metallic sodium-cooled Integral Fast

Breeder Reactor (IFR) which can make large amounts of weapons-grade plutonium

(Nixon). That program was subsequently halted in 1994 (Clinton) because the IFR

could make large amounts of weapons-grade plutonium. The Russians have a

successful fast sodium reactor of that general type, the BN-350 / BN-600 /

BN-800 series.

The drawing below shows the 70 foot

in diameter, 50 foot high reactor cell EBASCO designed in 1972 as

it would look installed in a modern Panamax concrete ocean-going barge with dual

3 foot thick concrete walls to contain the

reactor's radiation and heat. It is surrounded by a modern passive air

cooling system that uses the natural "chimney effect" of convection cooling to

carry away the cell's heat via an annulus located at the bottom of the reactor

cell.

_____________________________________________

Carbon Capture and Sequestration

(CCS) is being developed as both a retrofit and new plant installation

technology to capture up to 80% of the carbon dioxide emissions of a fossil fuel

power plant to minimize it's contribution to Global Warming. It has numerous

drawbacks. As an alternative to CCS, it should be more profitable to convert a

large power plant generating unit to the high-temperature heat of a molten salt

nuclear reactor module. If the power plant site is on navigable water, a

barge-mounted reactor cell offers many advantages over a fixed underground

reactor cell.

Download

"How the Thorium Reactor and Steam Generator Work" pdf

Return to Contents

________________________________________________________________________________________

Wyoming

legislators approve bill providing $10M for coal or natural gas to liquids FEED

study

31 October 2011 - Green Car Congress

Billings

Gazette. The Wyoming Legislature’s Joint Minerals, Business and Economic

Development Interim Committee recently approved a bill providing up to $10

million in matching funds to fund one or more front-end engineering and design

(FEED) studies to determine the feasibility of constructing and operating a

commercial scale facility which converts coal or natural gas to liquid fuels.

http://billingsgazette.com/news/state-and-regional/wyoming/article_c5ea34fb-aac2-5edd-a0d5-9a64ff94e631.html

CTL - FEED - 12LSO-0054.C1.pdf

A

representative of a company seeking to develop one such facility applauded the

committee’s decision. Cary Brus of Casper-based Nerd Gas Co., which is planning

a $1.7 billion natural gas-to-gasoline facility possibly located by Lake DeSmet,

said the proposed funding could help developers make a better pitch to potential

partners and financiers.

The

funding is part of a broader state effort to promote new uses for Wyoming's coal

and natural gas reserves. On Thursday, the committee approved a move to change

the name of the state’s Clean Coal Research Task Force, which funds coal

research, to the Advanced Conversion Technologies Task Force. The name

change and a shift in the task force’s mission allows the group to fund

conversion projects such as the minerals-to-liquids facilities instead of just

research into how to use the state’s coal in a more environmentally friendly

way.

________________________________________________________________________________________

American

geophysicist M. King Hubbert accurately predicted the 1970

American

geophysicist M. King Hubbert accurately predicted the 1970

The

coal-to-oil facility would be about the same size as the power plant when

you subtract the heating and coal handling equipment. The molten salt reactor

would be located between the electricity plant and the coal yard, with the

coal-to-oil plant located further out, between the reactor and the far side of

the coal yard for fire isolation. A

pipeline would carry the oil away from the CTL plant to either a nearby crude oil

pipeline or a rail car filling station located adjacent to the coal train dump

loop.

The

coal-to-oil facility would be about the same size as the power plant when

you subtract the heating and coal handling equipment. The molten salt reactor

would be located between the electricity plant and the coal yard, with the

coal-to-oil plant located further out, between the reactor and the far side of

the coal yard for fire isolation. A

pipeline would carry the oil away from the CTL plant to either a nearby crude oil

pipeline or a rail car filling station located adjacent to the coal train dump

loop.