CONCEPTUAL SKETCHES

Oil Gusher ! ![]() Map

Map

CONCEPTUAL SKETCHES

________________________________________________________________________________________

Part 4

The Application Conceptual Sketches

________________________________________________________________________________________

(Below) Carbon Capture and Sequestration Alternative

Fuel Switch: Existing Coal Burning Steam Plant Converted to Liquid Thorium

Carbon Capture and Sequestration

(CCS) is being developed as both a retrofit and new plant installation

technology to capture up to 80% of the carbon dioxide emissions of a fossil fuel

power plant to minimize it's contribution to Global Warming. It has numerous

drawbacks. As an alternative to CCS, it should be more profitable to convert a

large power plant generating unit to the high-temperature heat of a molten salt

nuclear reactor module. If the power plant site is on navigable water, a

barge-mounted reactor cell offers many advantages over a fixed underground

reactor cell.

Download

"How the Thorium Reactor and Steam Generator Work" pdf

_____________________________________________

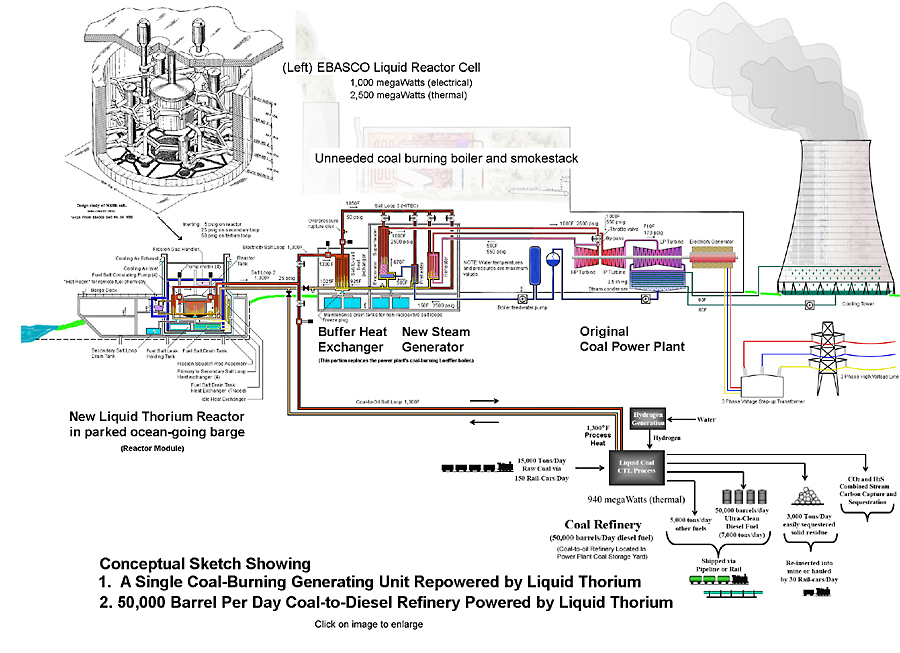

(Below) How a liquid thorium reactor can power both an existing coal power plant unit and a new coal-to-diesel refinery.

Fuel Switch: Existing Coal

Burning Steam Plant Repowered with Liquid Thorium + New CTL Oil Plant.

![]()

The new Coal-to-Oil plant takes advantage

of both the old coal handling equipment and the new liquid thorium reactor.

Example: (None.) Download

"How the Thorium Reactor and Steam Generator Work" pdf

"Don't assume that every 40 year old coal fired power station will simply shut down and disappear without a fight. I am very familiar with a four unit, 2,000 megaWatt power station of that vintage. There are firm plans for it to continue to 2023 at least. Its retiring Manager said as he departed last week that he hopes that the old girl will keep generating for another 30 years.

Be prepared to push the old as well as pull the new. Remember, what is needed is less carbon consumption. Merely adding non-carbon new plant could lock us all into continuation of the current unacceptable levels of CO2 generation for well over 30 years. Chinese and Indian generators being added to their grids weekly might still be around in 2080 or even later." - - John Bennetts commenting on "BraveNewClimate.com"

_____________________________________________

(Below) Mine-Mouth. How a liquid thorium reactor could power both a coal-to-diesel refinery and it's Stirling air turbine electricity generator.

Mine-Mouth CTL

Oil Refinery

![]()

Hydrogen Generation

components simulation.

Detailed

sulfur-iodine chemistry explanation.

_____________________________________________

(Below) The best way to convert small and medium size coal burning power plants to natural gas is to add "Combined Cycle" gas turbines while also replacing the the existing Loeffler coal boilers with new "Heat Recovery" boilers heated by the hot jet exhaust of the gas turbine engines. Very high generation efficiencies with very low emissions will be obtained this way.

Eventually low cost 1 gigaWatt (electrical) [2.5 gW (t)] liquid thorium reactors will be as available as natural gas turbines are today. Then, all the natural gas turbines can have their gas combustors replaced with heat transfer salt heat exchangers to become zero-emissions Stirling air turbines. All of the power plant's air turbines and heat recovery boiler units can be easily powered by a single large liquid thorium reactor's secondary salt feeding a multiple heat transfer salt loop gas turbine distribution manifold (See below.)

Fuel Switch:

Gas Turbine + Steam Turbine Combined Cycle Plant Repowered With Liquid Thorium.

![]()

Example: Bayside Above Gas

Turbine image Download and save Hi-rez pdf Download

"How the Thorium Reactor and Modified Gas Turbine Work" pdf

http://en.wikipedia.org/wiki/Combined_cycle About

Combined Cycle Conversions - Babcock & Wilcox pdf

Good text about

MSR - Repowering Existing Fossil Steam Plants - SEPRIL .pdf ( from:

http://soapp.epri.com/ )

Note: Some coal burning power plants have been

converted to natural gas simply by replacing their coal burners with gas

burners.

These power plants would be converted to liquid thorium as if they were still

coal burning power plants.

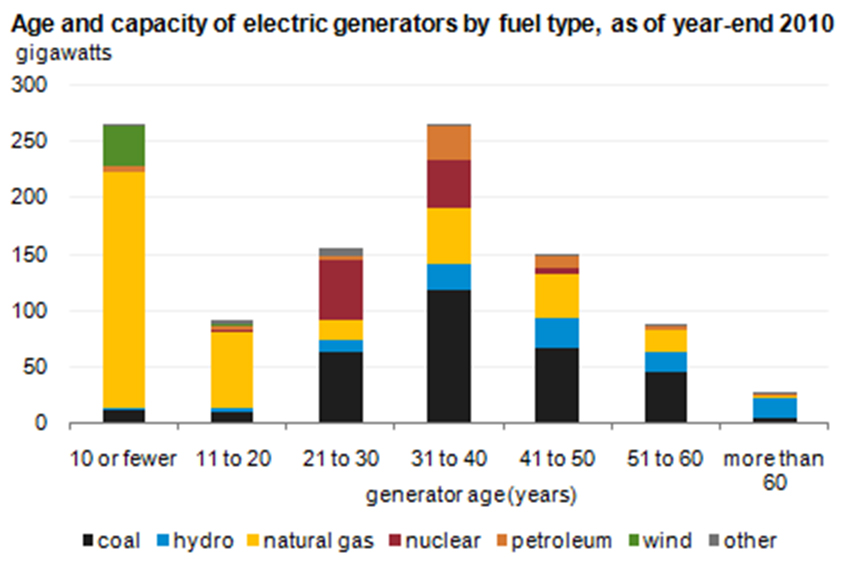

(Above - U.S. power generation.) Why being able to

convert gas power plants, in addition to coal power plants, to liquid thorium is

so important.

_____________________________________________

The Technology Modules In Greater Detail (Repeated from "Restoring America's Oil Independence" page.)

A variety of technologies were combined on this web page to assemble the "Making Fossil Fuels Green" concepts.

Everything used here has been invented, much of it is already in use in other commercial areas or in final commercial development by other countries.

1) THE NATURALLY SAFE, THORIUM-FUELED, MOLTEN SALT REACTOR Because of its temperature, and the way it delivers its heat, this is the only device mankind has at his disposal that can provide the unique power needed to halt Global Warming. Halting Global Warming

2) The EBASCO Reactor and its Confinement Cell Assembly

3) Barge Mounted Air Cooled Liquid Thorium Reactor Assembly

4) Underground Silo Air Cooled Liquid Thorium Reactor Assembly

5) Stirling Air Turbine Electricity Generator

6)

7) Coal Mine-Mouth Waterless Zero-Emissions Synthetic Oil Refinery

8)

9) Upgrading Existing Coal Burning Power Plants to Nuclear

10) A Zero-Emissions Synthetic Oil Refinery making Net-Zero Emissions Transportation Fuel

________________________________________________________________________________________